Preparation method of plastering anhydrite retarder

A technology for plastering gypsum and setting retarder, which is applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problem that the construction operation time cannot be satisfied, only a few minutes to ten minutes, and the strength of gypsum materials Large losses and other problems, to solve the problems of poor operability, low production cost, and meet the needs of production and construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

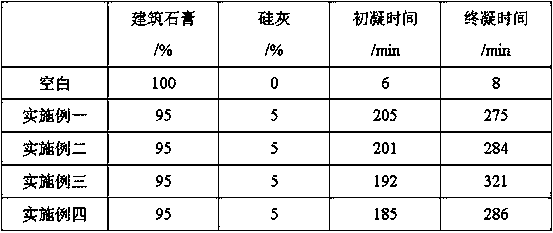

Embodiment 1

[0011] 2 parts of slag (specific surface area 416m 2 / kg), 4 parts of Portland cement clinker (specific surface area 397m 2 / kg), 0.1 parts of silica fume are mixed to make plaster gypsum retarder, and then added to building gypsum to make plaster plaster; the setting time of plaster plaster is tested according to the standard GBT28627-2012.

Embodiment 2

[0013] 1 part of slag (specific surface area 537m 2 / kg), 6 parts of Portland cement clinker (specific surface area 438m 2 / kg), 0.3 parts of silica fume are mixed to make plaster retarder, and then added to construction gypsum to make plaster plaster; the setting time of plaster plaster is tested according to the standard GBT28627-2012.

Embodiment 3

[0015] 6 parts of slag (specific surface area 434m 2 / kg), 1 part of Portland cement clinker (specific surface area 424m 2 / kg), 0.4 parts of silica fume are mixed to make plaster retarder, and then added to building gypsum to make plaster; the setting time of plaster is tested according to the standard GBT28627-2012.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com