Method and device for dynamic non-destructive measurement of CRTSII type plate-type ballastless track seam

A slab ballastless track, non-destructive testing technology, applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, can solve the problems affecting the stability and smoothness of train operation, failing to meet the requirements of track safety early warning, and high detection and maintenance costs. The results are intuitive and reliable, meeting the effect of short skylight time and saving detection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

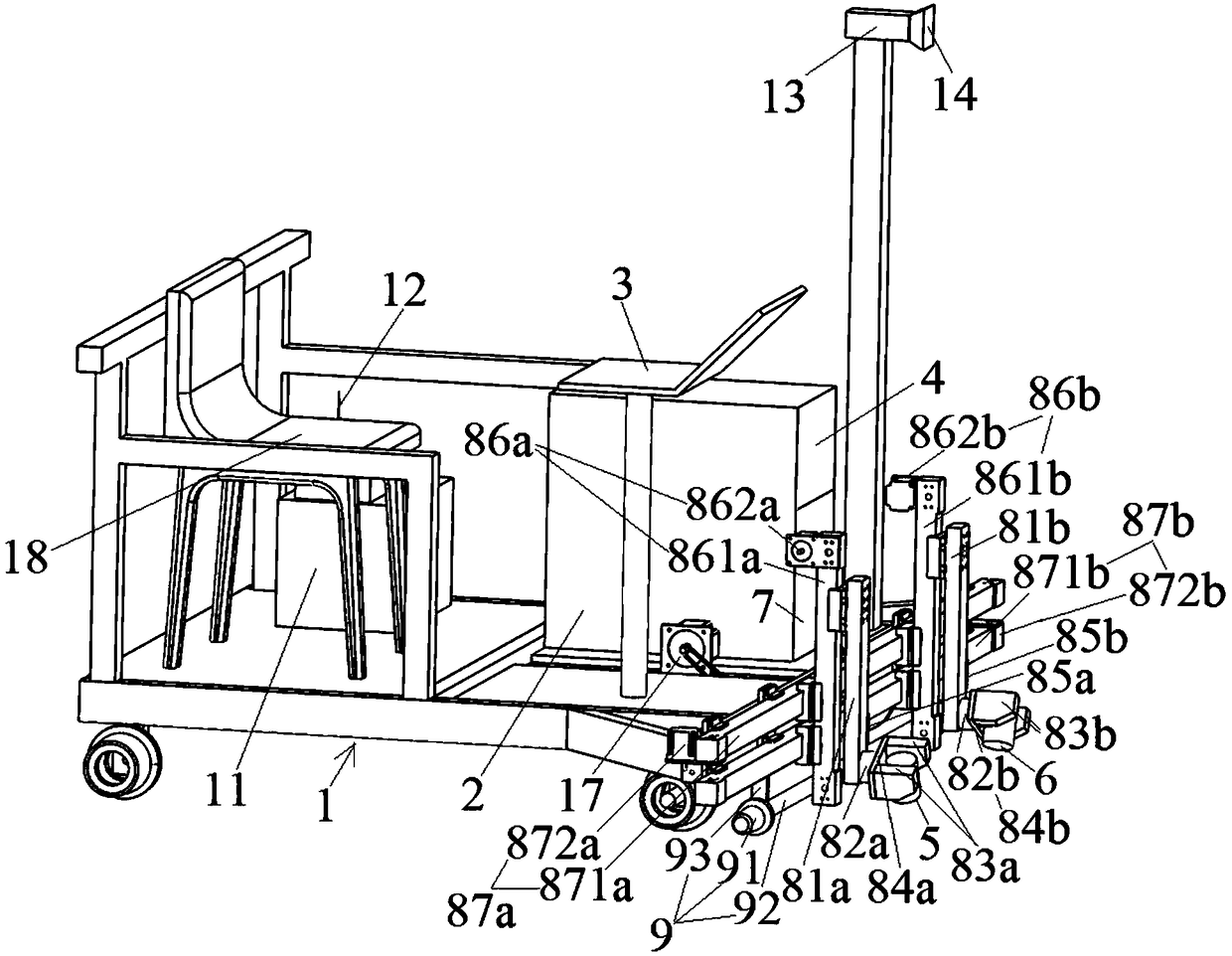

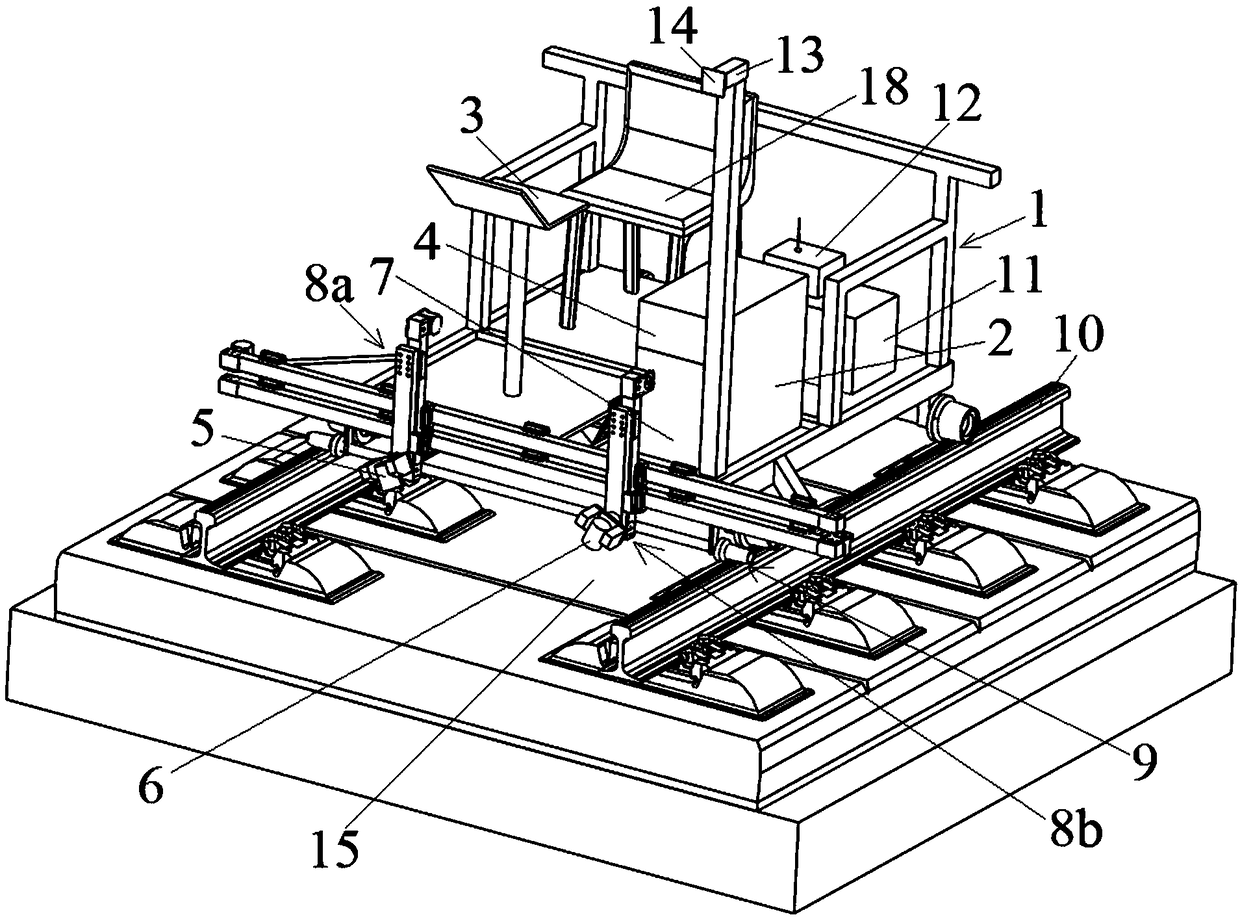

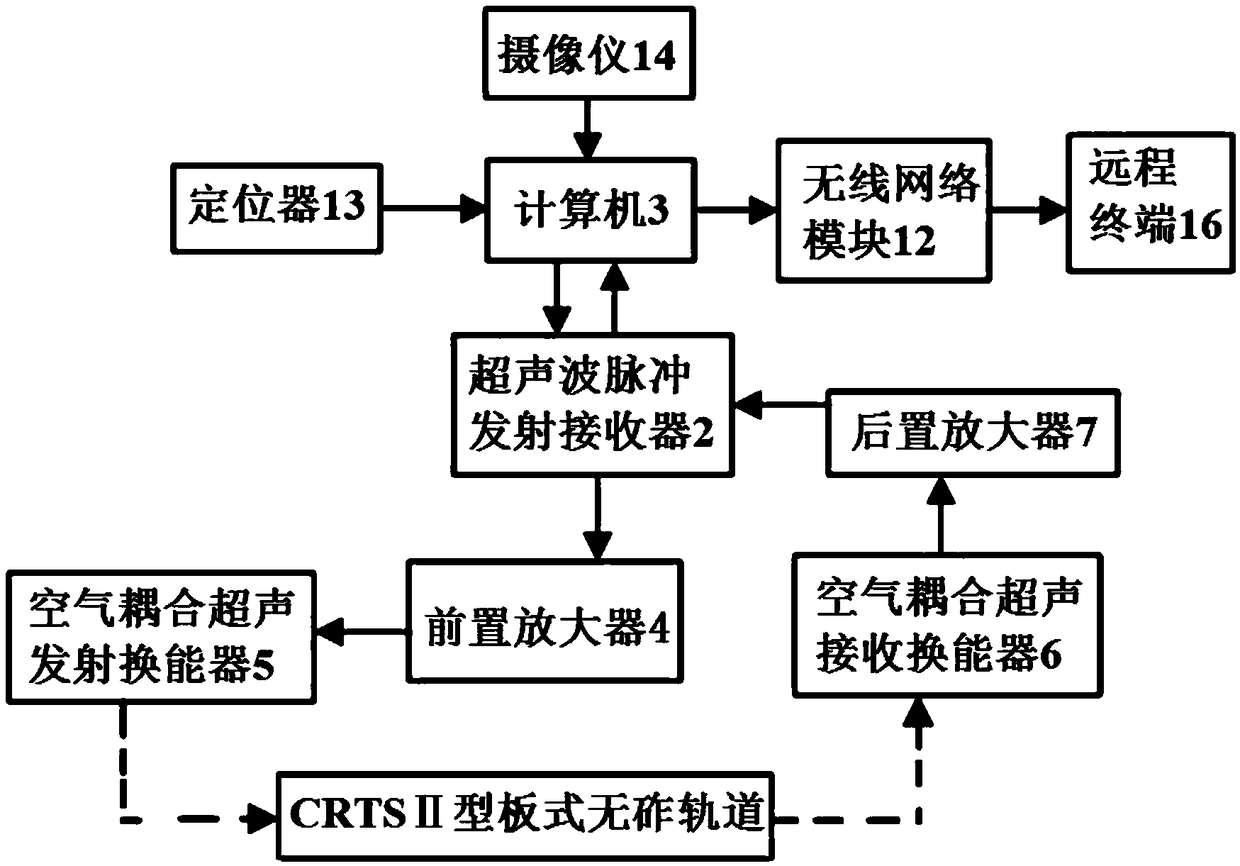

[0028] see figure 1 with figure 2 As shown: a device for dynamic non-destructive testing CRTS II type ballastless track separation provided by this embodiment, including: track inspection trolley 1 and ultrasonic pulse transmitter receiver 2 and computer 3 arranged on track inspection trolley 1, Also includes a preamplifier 4, an air-coupled ultrasonic transmitting transducer 5, an air-coupled ultrasonic receiving transducer 6 and a post-amplifier 7, the air-coupled ultrasonic transmitting transducer 5 and an adaptive displacement feedback The adjustment device 8a is connected, and the air-coupled ultrasonic receiving transducer 6 is connected with an adaptive displacement feedback adjustment device 8b, and the adaptive displacement feedback adjustment devices 8a and 8b are both fixedly connected to the front end of the track inspection trolley 1 .

[0029]The adaptive displacement feedback adjustment device 8a / 8b includes a mounting plate 81a / 81b on which a rotating motor 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com