Wide-angle lens and panoramic photography system

A wide-angle lens and lens technology, which is applied in the field of wide-angle lens and panoramic camera system, can solve the problems of high processing difficulty, short time, and inability to correct high-order aberrations well, and achieve the effect of small overall length, processing difficulty and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

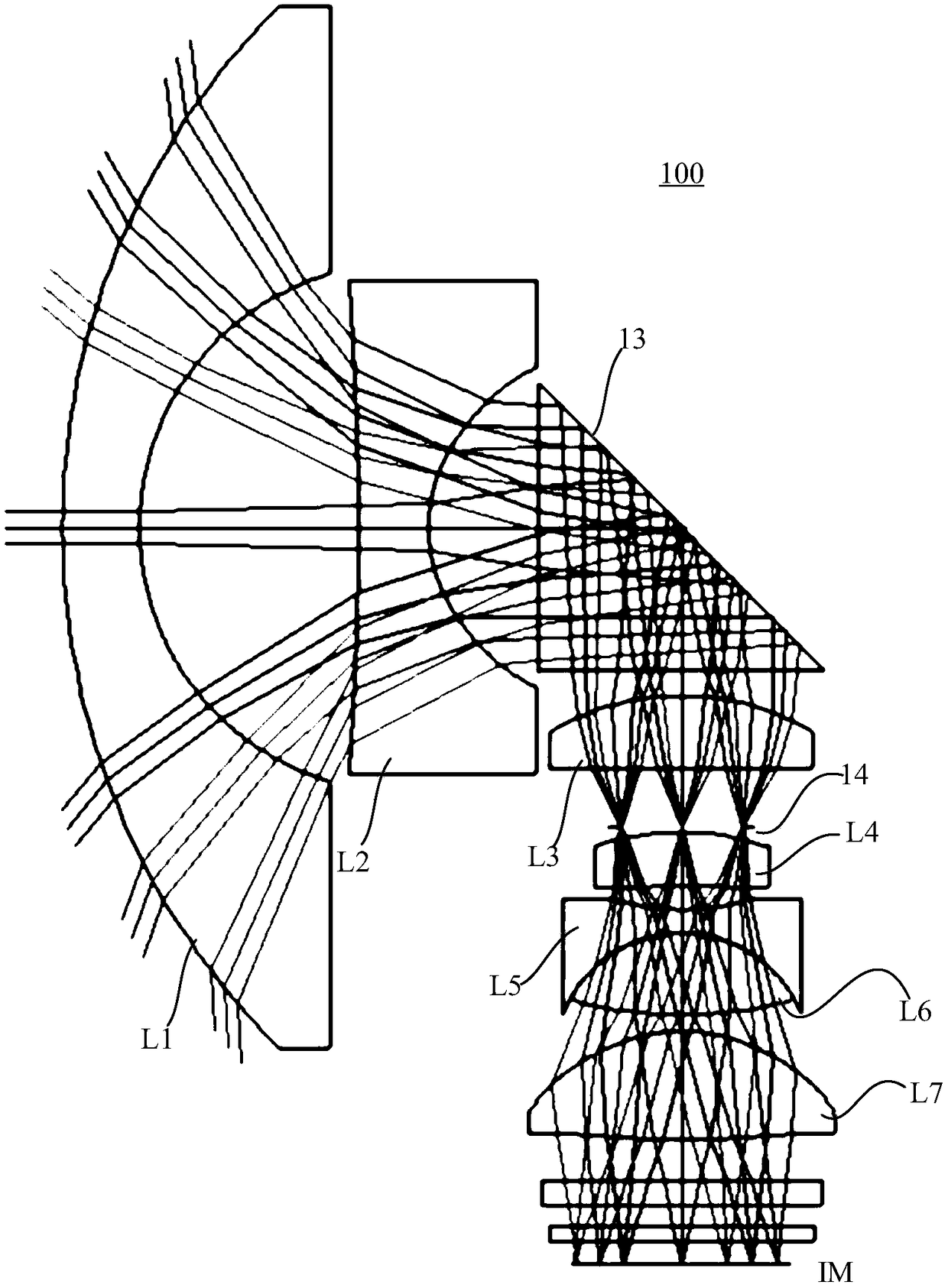

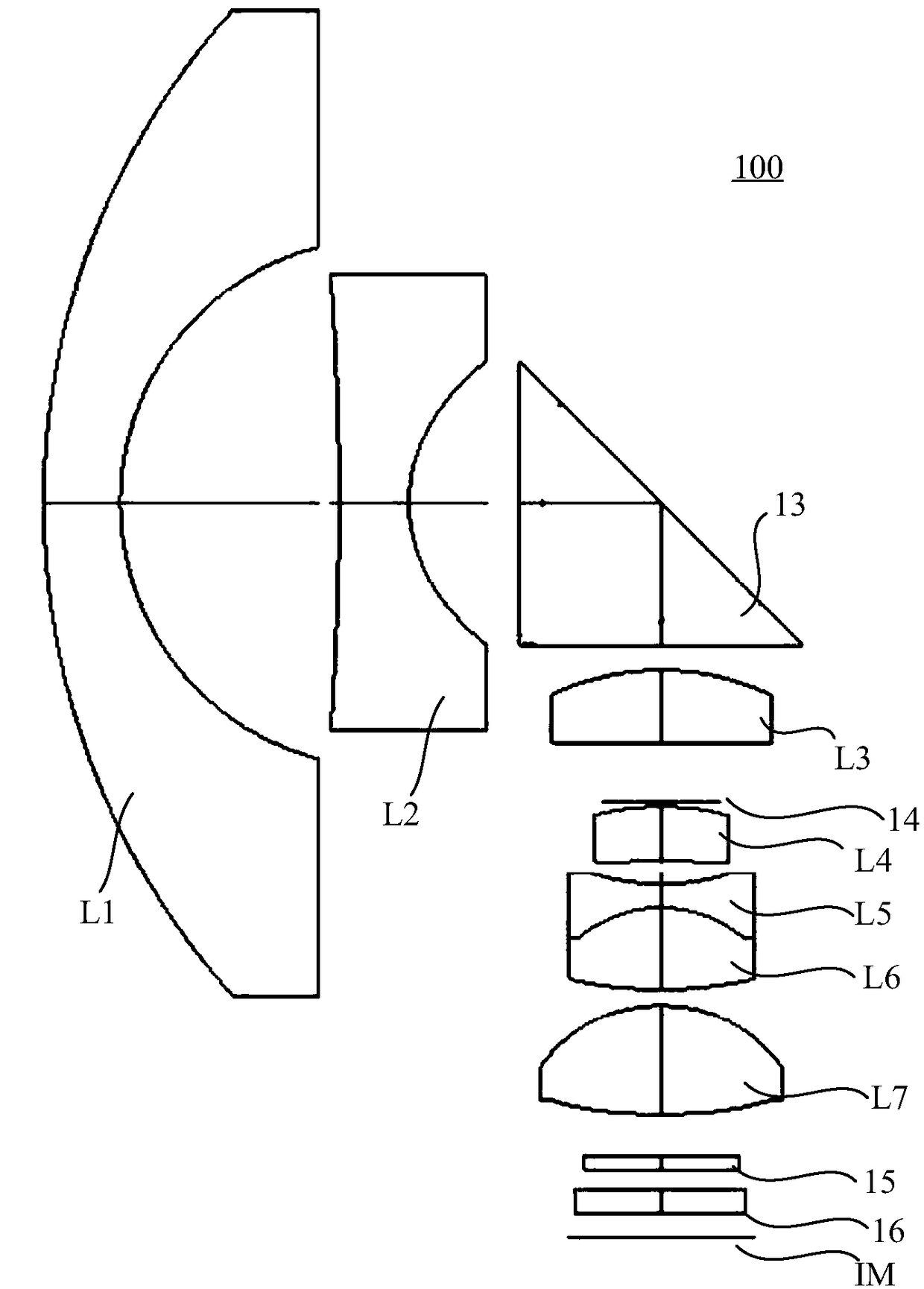

[0027] see figure 1 The wide-angle lens 100 provided by the first embodiment of the present invention includes a first lens L1, a second lens L2, a third lens L3, a fourth lens L4, a fifth lens L5, and a sixth lens in order from the object side to the imaging surface IM. L6 , the seventh lens L7 and the reflective element 13 .

[0028] The first lens L1 has negative refractive power, and the image-side surface is concave, and the first lens L1 is a spherical mirror in a meniscus shape. The first lens L1 can be a glass lens with a higher refractive index. The high refractive index material can achieve fast light collection, reduce the inclination angle of the image-side surface of the first lens L1, and reduce the processing cost.

[0029] The second lens L2 has negative refractive power, and the image-side surface is concave.

[0030] The third lens L3 has positive refractive power and is a spherical mirror.

[0031] The fourth lens L4 has positive refractive power, and the...

no. 2 example

[0093] see Image 6 , shows a structural diagram of a wide-angle lens 200 provided in this embodiment. The wide-angle lens 200 of the present embodiment is substantially the same as the wide-angle lens 100 of the first embodiment, except that the Abbe numbers of the fifth lens L5 and the sixth lens L6 of the wide-angle lens 200 of the present embodiment are different, and the effect on chromatic aberration The ability to compensate is different. Specific lens-related parameters of each lens are shown in Table 3.

[0094] table 3

[0095]

[0096] Please refer to Table 4, which shows the parameters related to the aspheric surface of each lens in this embodiment.

[0097] Table 4

[0098]

[0099]

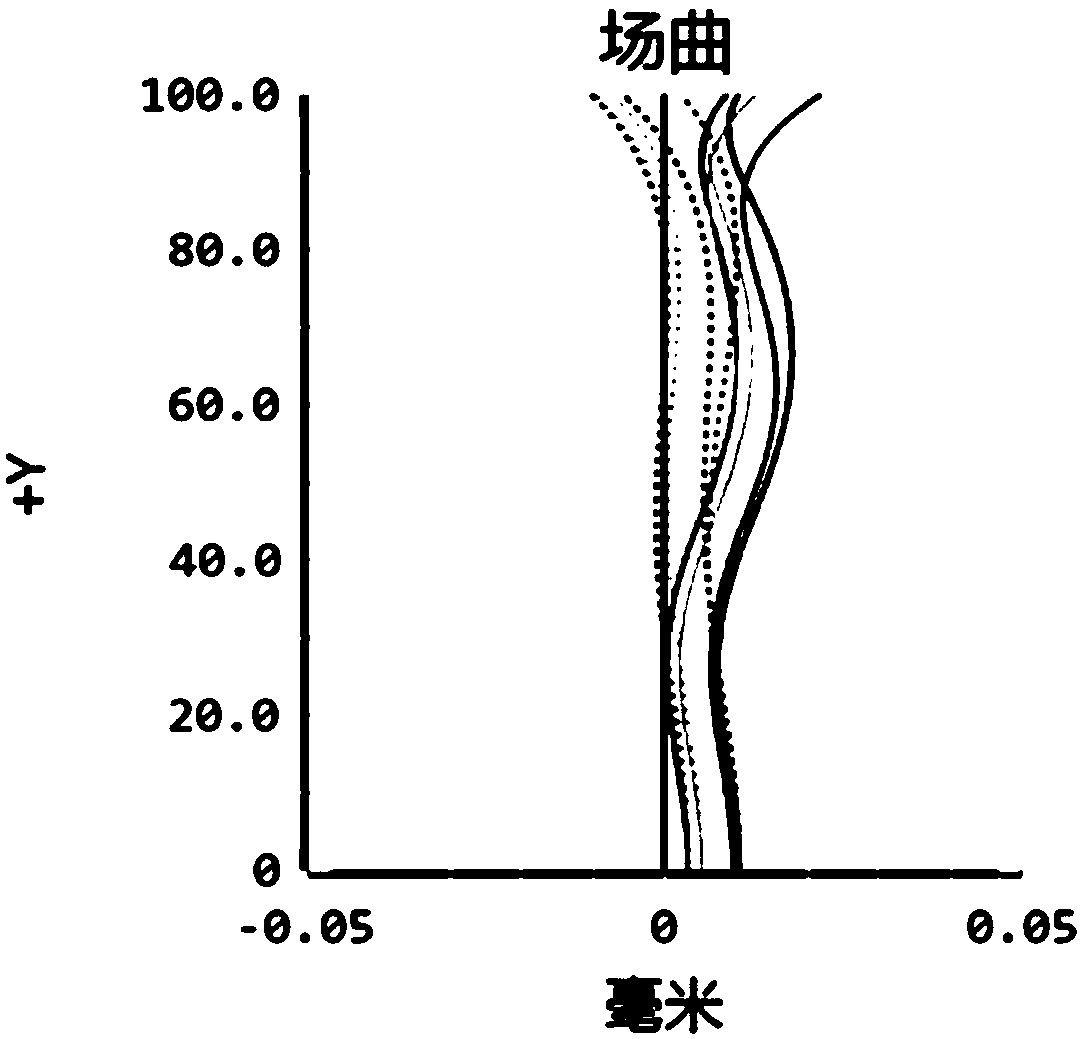

[0100] The field curvature and F-Theta distortion curves of the wide-angle lens 200 provided in this embodiment are as follows: Figure 7 with Figure 8 As shown, it can be seen from the figure that the field curvature and distortion of the wide-angle lens 200 are well...

no. 3 example

[0102] see Figure 10 , shows a schematic diagram of the structure of a wide-angle lens 300 provided in this embodiment. The wide-angle lens 300 in this embodiment is roughly the same as the wide-angle lens 100 in the first embodiment. The chief ray angle has a different effect. Specifically, the stop 14 is located between the fourth lens L4 and the fifth lens L5.

[0103] Please refer to Table 5, which shows parameters related to each lens of the wide-angle lens 300 in this embodiment.

[0104] table 5

[0105]

[0106]

[0107] Please refer to Table 6, which shows the parameters related to the aspheric surface of each lens in this embodiment.

[0108] Table 6

[0109]

[0110] The field curvature and F-Theta distortion curves of the wide-angle lens 300 provided in this embodiment are as follows: Figure 11 with Figure 12 As shown, it can be seen from the figure that the field curvature and distortion of the wide-angle lens 300 are well corrected. Figure 13 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total length | aaaaa | aaaaa |

| Diagonal length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap