Cable joint protective clip and cable joint protective clip assembly

A cable joint and protective clip technology, applied in the direction of connecting/terminating cable equipment, etc., can solve the problems of poor cable joint contact, increased power outage time, low work efficiency, etc., to reduce the probability of equipment tripping and other events, high Safety in use and convenient insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

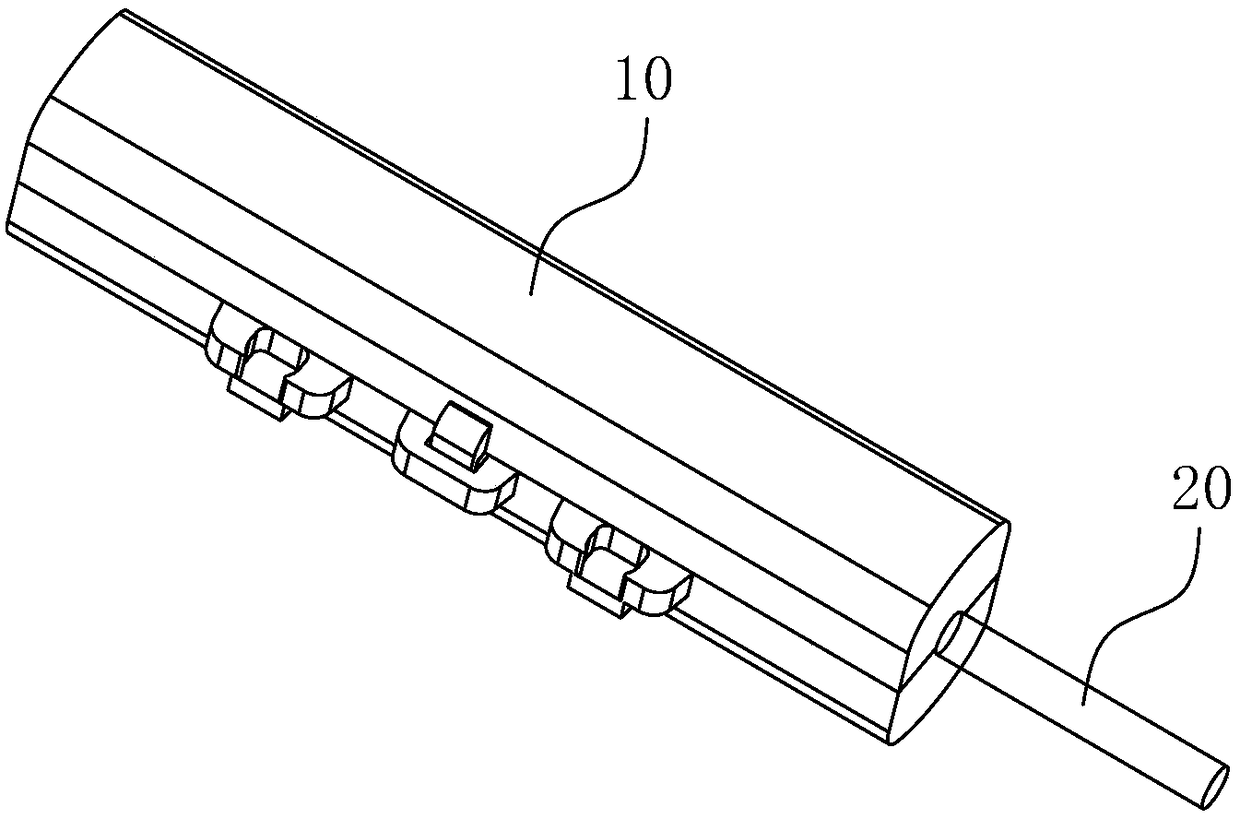

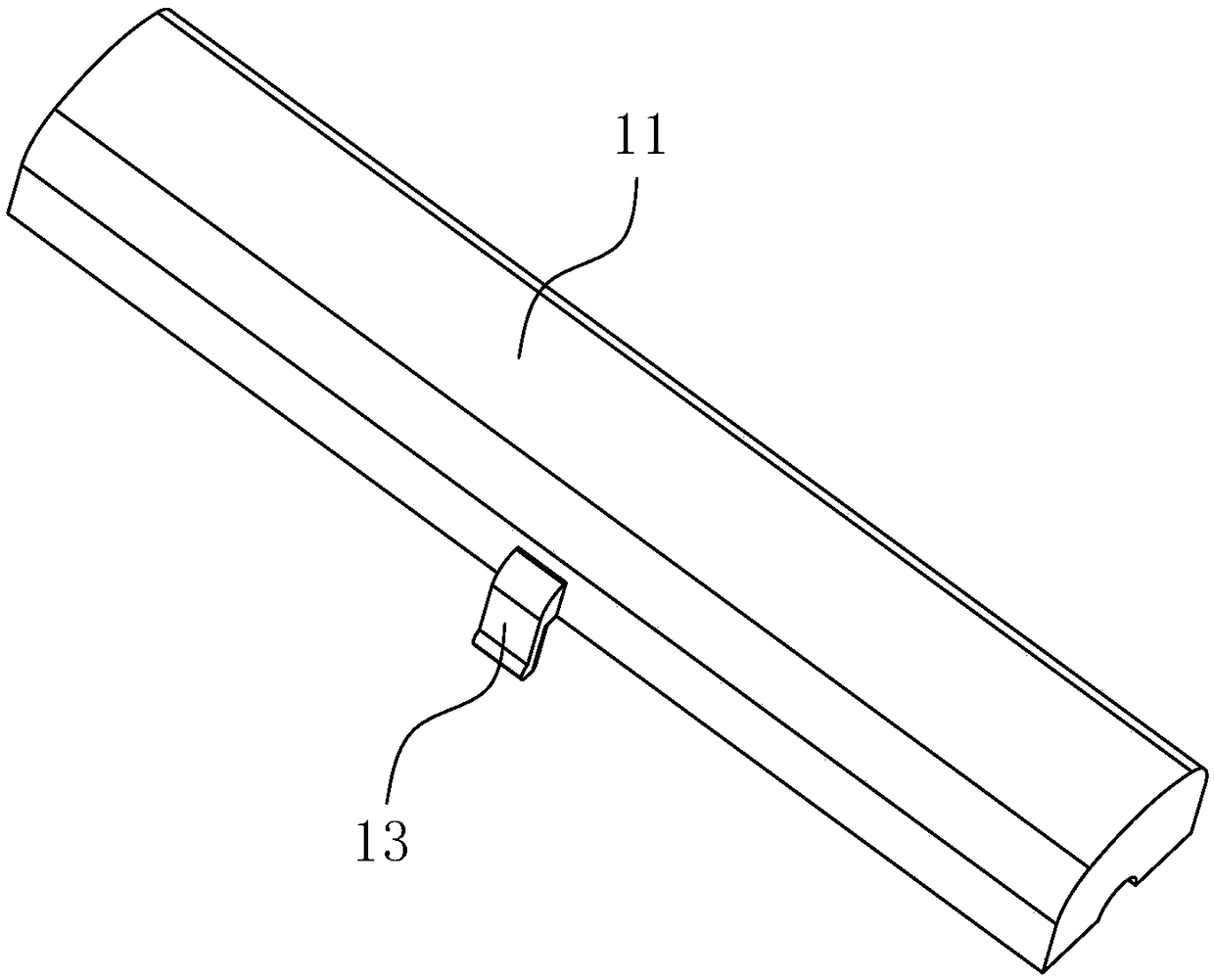

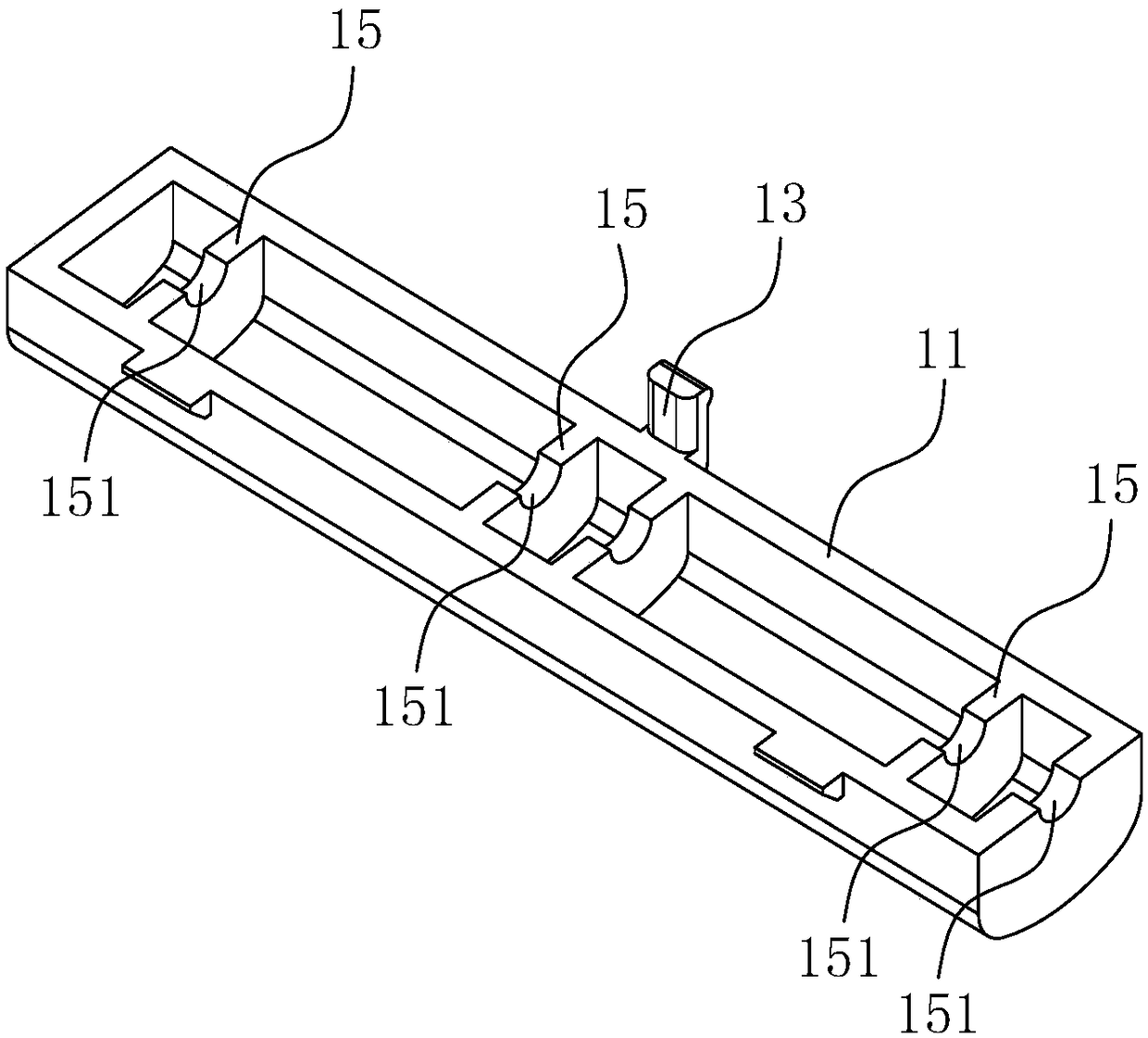

[0048] see Figure 1 to Figure 4 ,in, figure 1 It is a structural schematic diagram of the cable joint protection clamp 10 and the cable 20 according to the embodiment of the present invention, figure 2 with image 3 It is a structural schematic diagram of the first clip body 11 of the embodiment of the present invention, Figure 4 It is a schematic structural diagram of the second clip body 12 of the embodiment of the present invention.

[0049] The cable joint protection clip 10 of the embodiment of the present invention includes a first clip body 11 and a second clip body 12 .

[0050] The first clamping body 11 is matched with the second clamping body 12 , and the first clamping body 11 and the second clamping body 12 are opened and closed.

[0051] Both the first clamping body 11 and the second clamping body 12 are provided with a corresponding clamping structure, and the clamping structure is used to clamp the cable connector.

[0052] Both the first clip body 11 a...

Embodiment 2

[0083] see Figure 1 to Figure 5 ,in, Figure 5 It is a structural schematic diagram of the cable joint protective clip assembly of the embodiment of the present invention.

[0084] The cable joint protection clamp assembly of the embodiment of the present invention includes a plurality of the aforementioned cable joint protection clamps 10 .

[0085] The cable joint protection clip 10 includes a first clip body 11 and a second clip body 12 .

[0086] The first clamping body 11 is matched with the second clamping body 12 , and the first clamping body 11 and the second clamping body 12 are opened and closed.

[0087] Both the first clamping body 11 and the second clamping body 12 are provided with a corresponding clamping structure, and the clamping structure is used to clamp the cable connector.

[0088] Both the first clip body 11 and the second clip body 12 are made of insulating materials.

[0089] A plurality of cable joint protective clips 10 are arranged side by side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com