Preparation method of instant butter spicy bean sauce

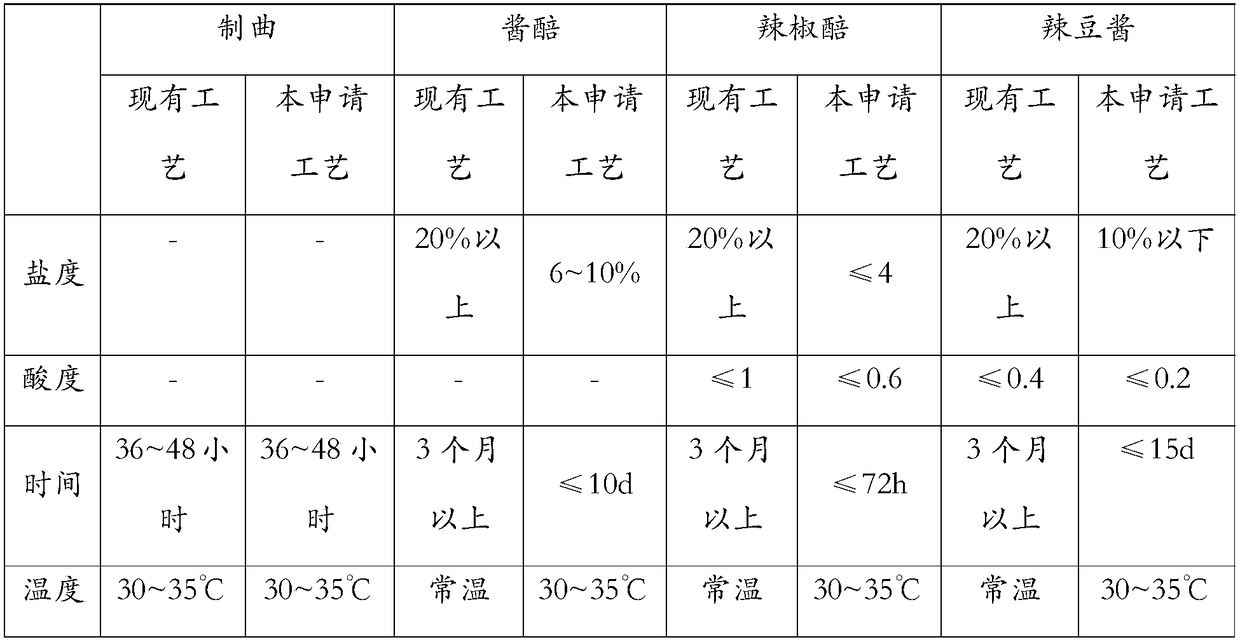

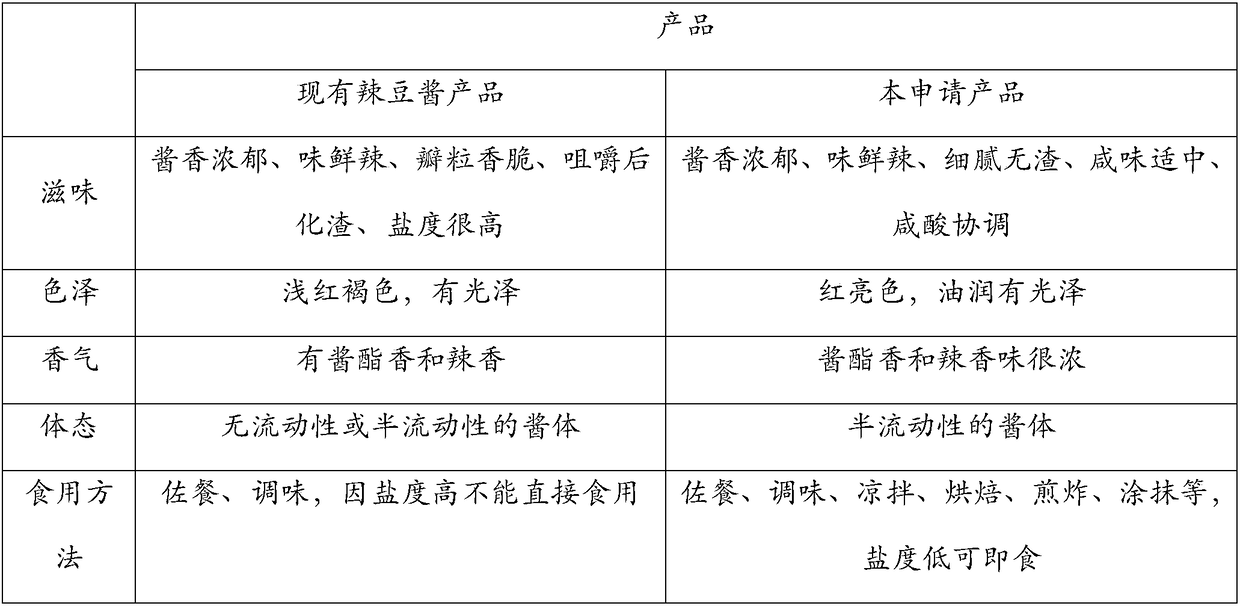

A technology for oil-spicy soybean paste and soybean paste, which is applied in the field of food processing, can solve the problems of long cycle and slow fermentation, and achieve the effect of reducing salinity, reducing production cost and conforming to the development trend of the industry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

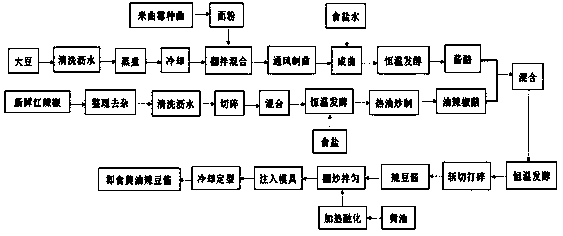

Method used

Image

Examples

Embodiment 1

[0029] A kind of instant butter chili bean sauce preparation method, it comprises the following steps:

[0030] 1) Preparation of oily chili fermented grains

[0031] (1) Arrange the fresh peppers to remove impurities, wash and drain the water, chop and break into chili sauce with a particle size of 3-5mm (water content is 70%), add salt accounting for 4% of the mass of chili sauce, mix Stir evenly, and ferment at 30-35°C until the acidity reaches 0.6%, and the fermentation ends;

[0032] (2) Take by weighing 5kg of chili sauce prepared by the above (1) step, then weigh 5kg of rapeseed oil, when the oil temperature is burned to 180°C, turn off the fire source, and when the oil temperature is cooled to 150°C, pour Put in chili sauce, stir-fry over high heat until the water content of the chili grains is ≤50%, then turn off the fire source to prepare oily chili grains for later use.

[0033] 2) Production of the finished song:

[0034] Weigh 2 kg of dry soybeans and soak them...

Embodiment 2

[0042] A kind of instant butter chili bean sauce preparation method, it comprises the following steps:

[0043] 1) Preparation of oily chili fermented grains

[0044] (1) Arrange the fresh peppers to remove impurities, wash and drain the water, chop and break into chili sauce with a particle size of 3-5mm (water content is 65%), add salt accounting for 4% of the mass of the sauce, mix Stir evenly, and ferment at 30-35°C until the acidity reaches 0.6%, and the fermentation ends;

[0045] (2) Weigh 5kg of chili sauce prepared according to the above step (1), measure 6kg of rapeseed oil according to the mass ratio of chili sauce: rapeseed oil = 1:1.2, heat the oil to 180°C, and turn off Fire source, when the oil temperature is cooled to 150°C, pour in the chili sauce, stir-fry on high heat until the water content of the chili grains is ≤50%, turn off the fire source, and prepare the oily chili grains for later use.

[0046] 2) Production of the finished song:

[0047]Weigh 3 k...

Embodiment 3

[0062] Adopt the preparation method among the embodiment 1 to carry out the preparation of ready-to-eat butter chili bean paste, steps and parameters are all the same as embodiment, but change the mass ratio of oil chili unstrained spirits and sauce unstrained spirits, and the quality of low-salt chili bean paste and unsalted butter Compare. Among them, the mass ratio of oily chili fermented grains and sauce fermented grains is 1:0.1; the mass ratio of low-salt chili bean paste to unsalted butter is 1:0.1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com