High-quality safe radish pickles and preparation method thereof

A production method and high-quality technology, applied in food ingredients, food science, applications, etc., can solve problems such as high nitrite content, unstable quality, and high salinization of pickles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

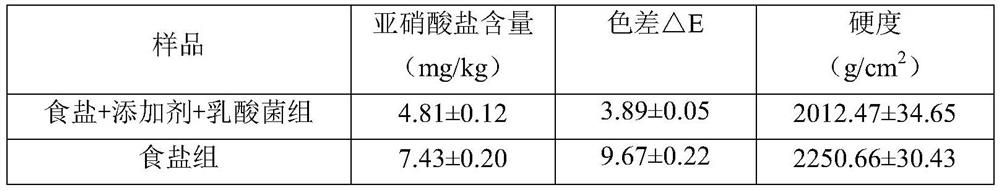

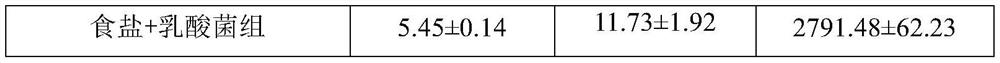

[0023] + + Additive group of lactic acid salt: white radish pick up fresh, cleaned, cut into blocks of 2 × 2 × 2cm, was charged 50g can take the bottle, 5g of salt can evenly spread on radish bottle and allowed to stand 60min after injection containing phytic acid (0.05 g of), a mixed solution of ascorbic acid (0.20 g) and L- cysteine (0.20 g) of soy sauce and 150mL 150mL of purified water, and then the vial 6% Lactic acid bacteria can access sealing at at 25 ℃ marinated 1-7 days.

[0024] Salt group: white radish pick up fresh, cleaned, cut into blocks of 2 × 2 × 2cm, was charged 50g can take the bottle, 10g of salt can evenly spread on radish bottle and allowed to stand 60min, injection 150mL soy sauce and a mixed solution of 150mL of purified water, to seal, at at 25 ℃ marinated 1-7 days.

[0025] + Group of lactic acid salt: white radish pick up fresh, cleaned, cut into blocks of 2 × 2 × 2cm, was charged 50g can take the bottle, 5g of salt can evenly spread on radish bottle,...

Embodiment 2

[0032] Pick fresh white radish, cleaned, cut into 2 × 2 × 2cm cake, was charged 50g can take the bottle, 5g of salt can evenly spread on radish bottle, allowed to stand for 60min, soy sauce and 150mL 150mL injection a mixed solution of pure water, and after sealing the bottle can access to 4% of lactic acid bacteria, to marinated at 25 ℃ 1-7 days. Marinated measurement of the nitrite content of 7 days, color and hardness radish pickles.

[0033] Nitrite content of the samples is 5.96 ± 0.04mg / kg, the color difference △ E is 12.02 ± 1.10, a hardness of 2567.10 ± 17.80g / cm 2 . Compared with the group of lactic acid + salt of Example 1, the amount of lactic acid bacteria inoculated a 2% reduction, a corresponding increase in the nitrite content 0.51mg / kg, 0.29 chromatic aberration increases, increase in hardness of 224.38g / cm 2 But a small amount of lactic acid bacteria inoculum can also significantly reduce the generation amount of nitrite salt group as compared with Example...

Embodiment 3

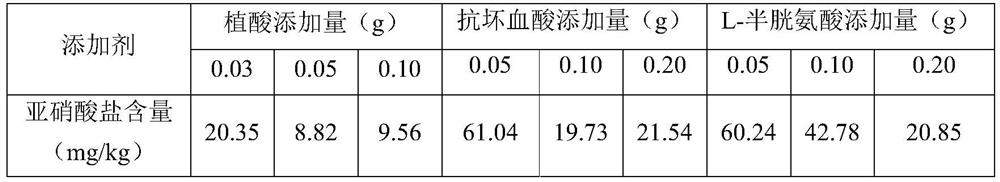

[0035] Pick fresh white radish, cleaned, cut into blocks of 2 × 2 × 2cm, was charged 50g can take the bottle, 5g of salt can evenly spread on radish bottle, allowed to stand 60min, injection containing phytic acid ( 0.05 g of), a mixed solution of ascorbic acid (0.10 g) and L- cysteine (0.20 g) of soy sauce and 150mL 150mL of purified water, and then sealed to 6% of lactic acid bacteria can vial access to at 25 ℃ marinated 1-7 days. Marinated measurement of the nitrite content of 7 days, color and hardness radish pickles.

[0036] Nitrite content of the samples is 5.30 ± 0.15mg / kg, the color difference △ E was 2.58 ± 1.10, a hardness of 2235.03 ± 17.46g / cm 2 . As compared with Example group of lactic acid salt + additive + 1, the added amount of reduced ascorbic acid 0.10g, nitrite content corresponding increase of 0.49mg / kg, 1.31 chromatic aberration is reduced, increase in hardness of 222.56g / cm 2 Added 1-fold reduced amount of ascorbic acid, nitrite content of the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com