Molding device for rice noodles

A molding equipment and equipment technology, applied in food molding, mixer, food science and other directions, can solve problems such as poor taste, uneven texture, rough rice noodles, etc., to increase pressure, prevent splashing, and facilitate shearing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

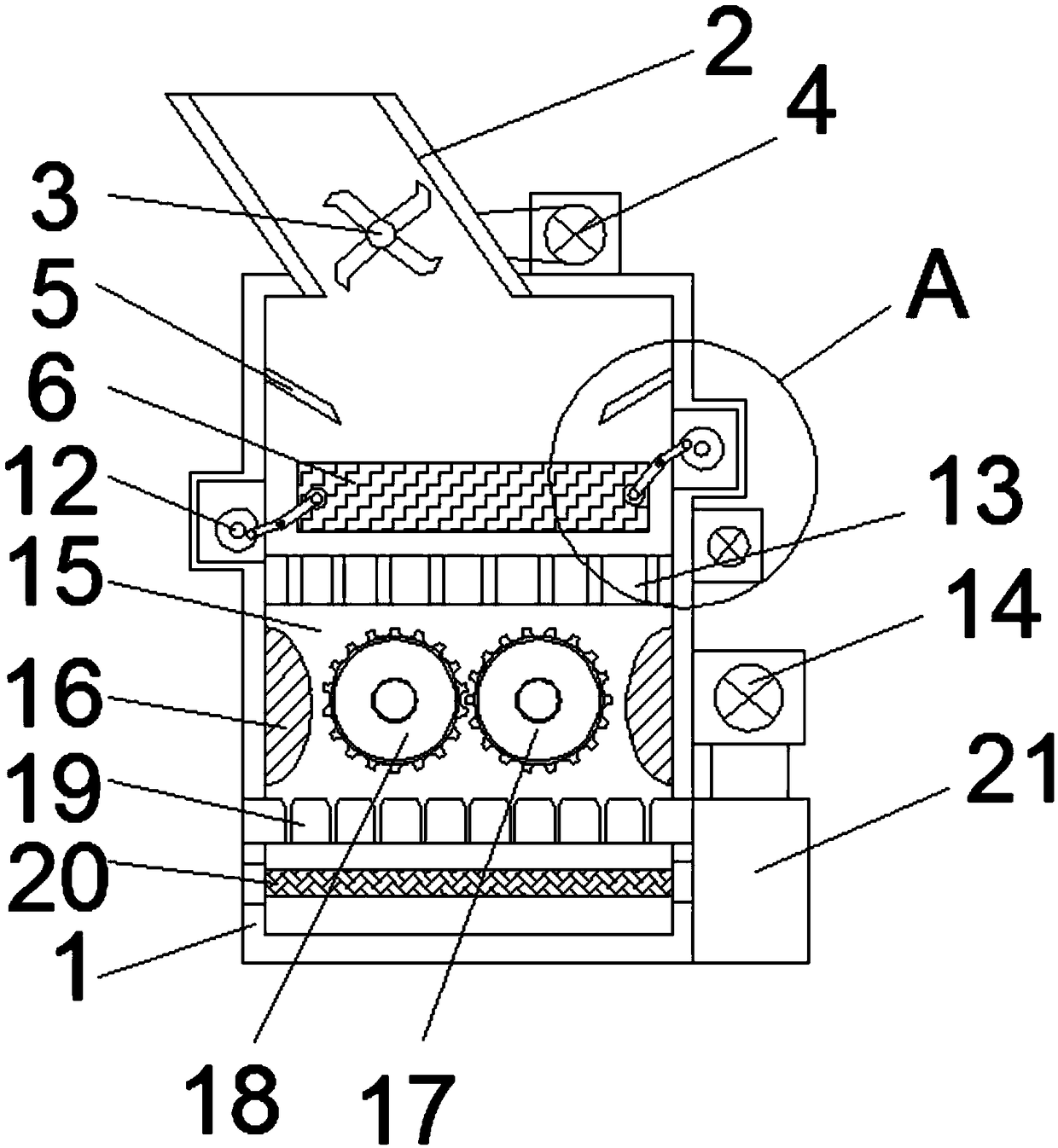

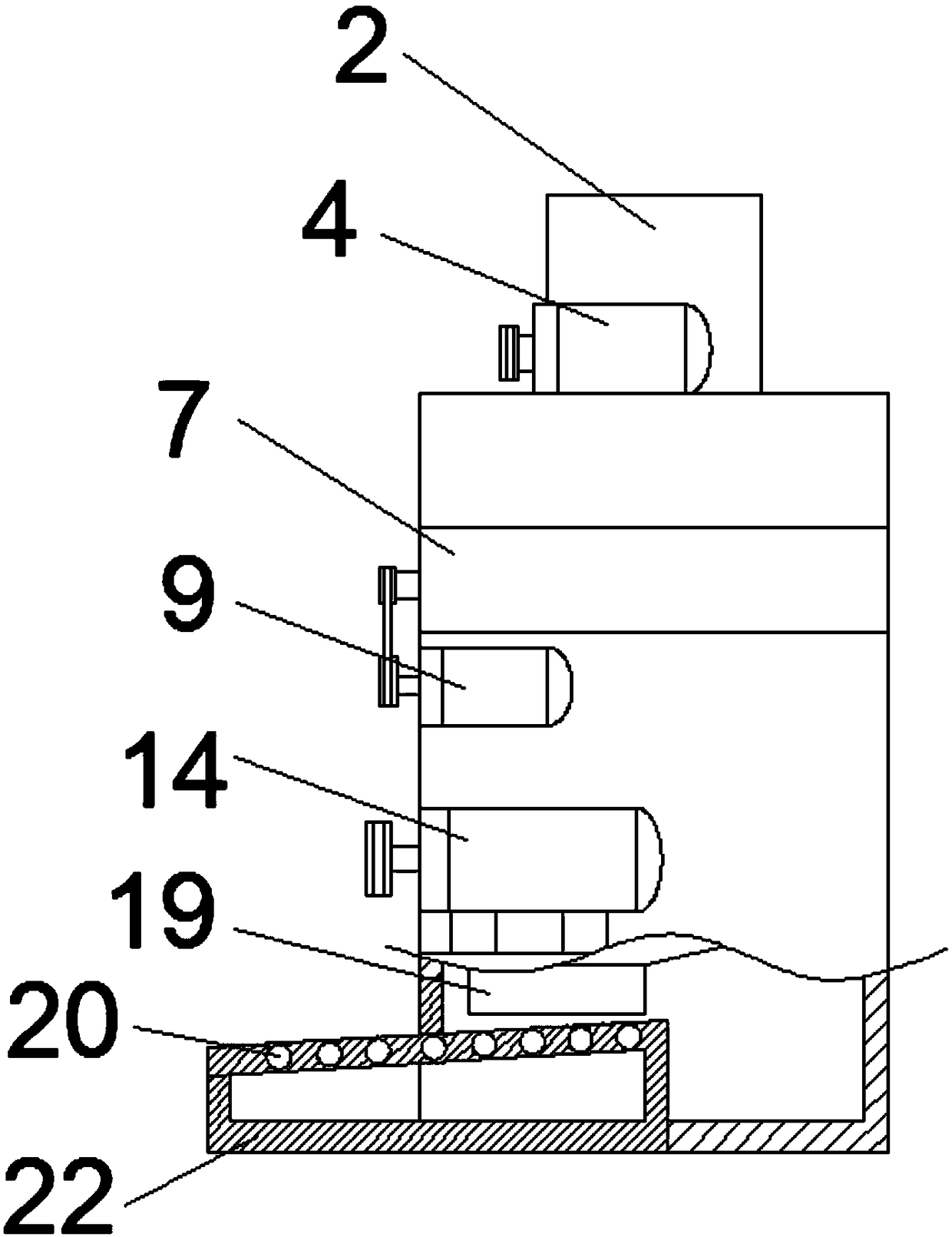

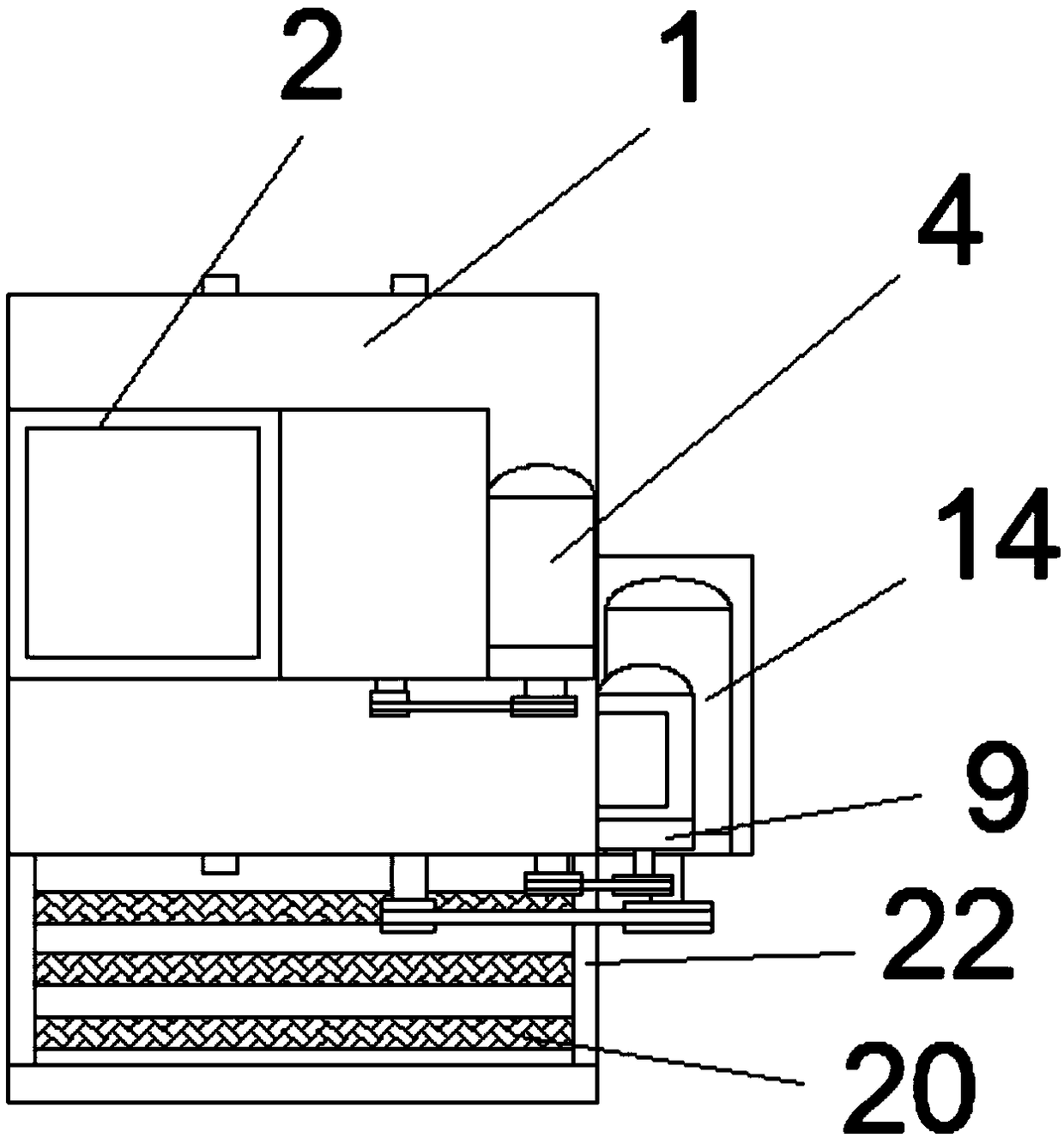

[0021] Such as Figure 1-Figure 4 As shown, a kind of rice noodle forming equipment proposed by the present invention includes a device body 1, a rice noodle inlet 2 and a grinding disc 6, a rice noodle inlet 2 is arranged on the left side of the upper end of the device body 1, a stirring impeller 3 is arranged in the rice noodle inlet, and the stirring impeller 3 is front and rear The two ends are rotationally connected with the rice noodle inlet 2 walls by a rotating shaft. The right side of the upper end of the device body 1 is provided with a first motor 4. The front end of the first motor 4 is provided with a motor wheel. The motor wheel is connected with the stirring impeller 3 by a belt. The upper part of the device body 1 Left and right baffles 5 are symmetrically arranged, and a millstone 6 is arranged in the equipment body 1 below the baffle plate 5. The left end of the millstone 6 is connected to the second turntable 12 through a connecting rod, and the right end of ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap