Polymer water-based paint raw material grinding device

A water-based coating and grinding device technology, applied in cocoa, grain processing, chemical instruments and methods, etc., can solve the problems of inability to grind materials, short service life, and unfavorable materials to be fully processed, and achieve the effect of energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

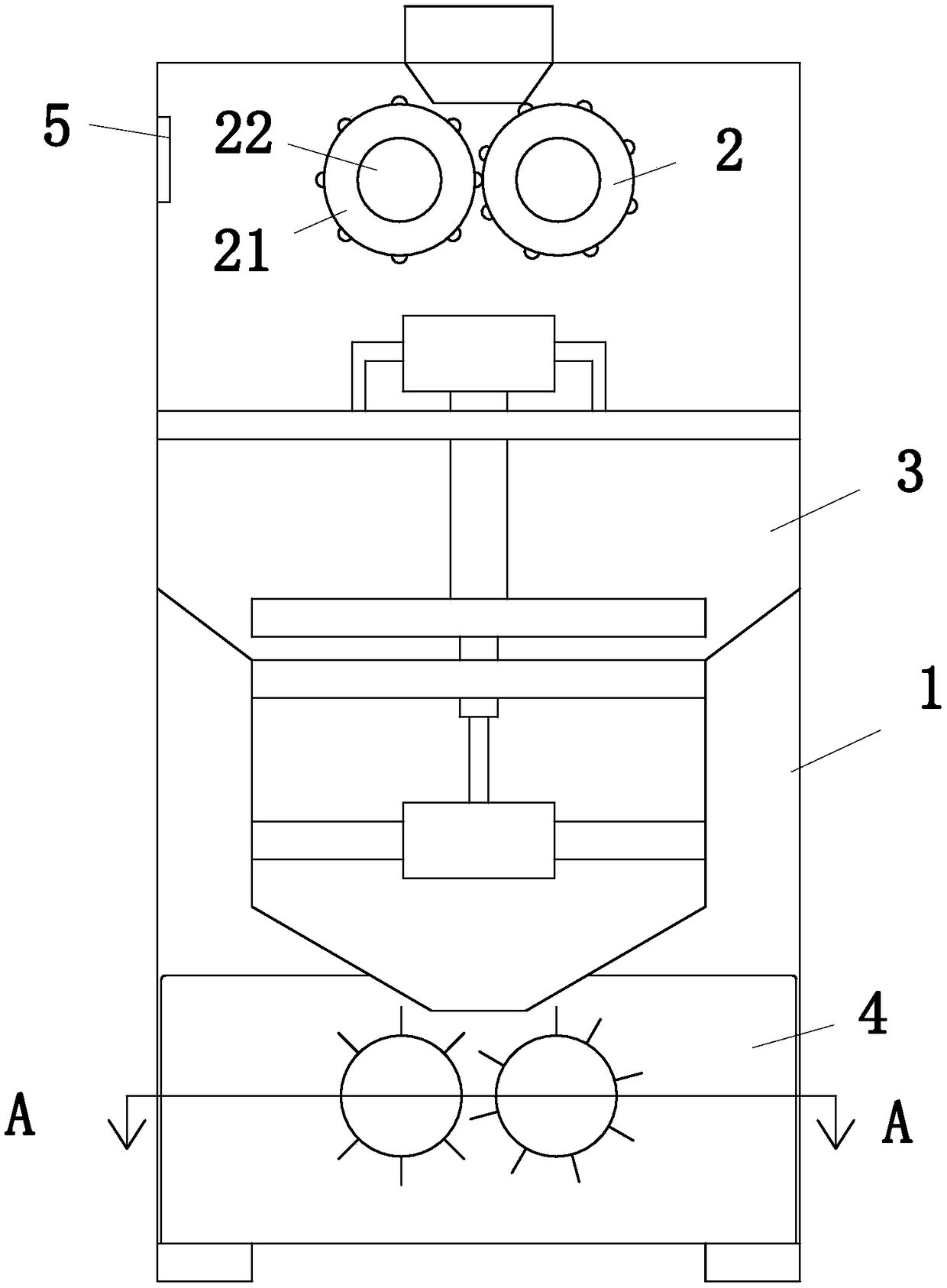

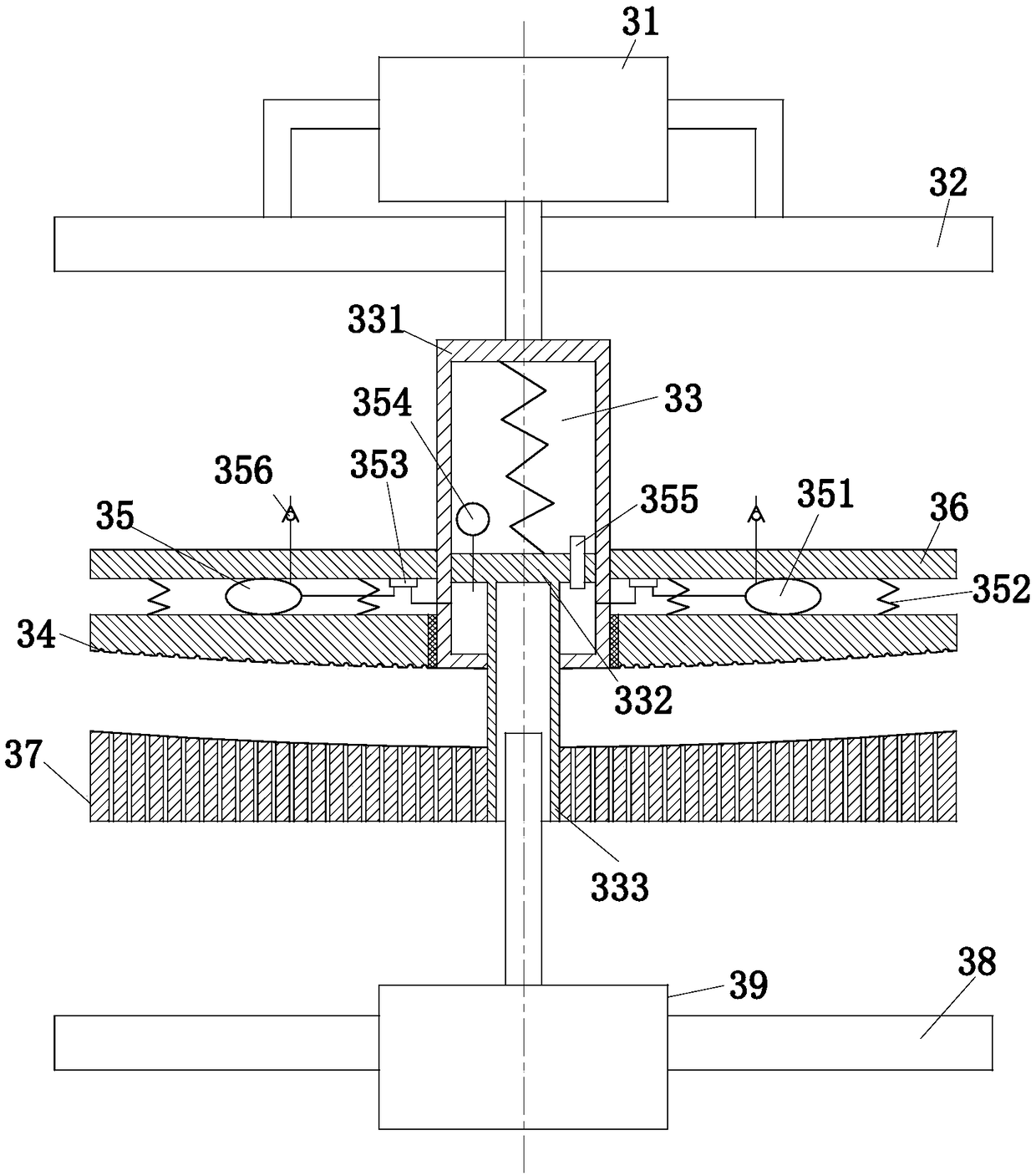

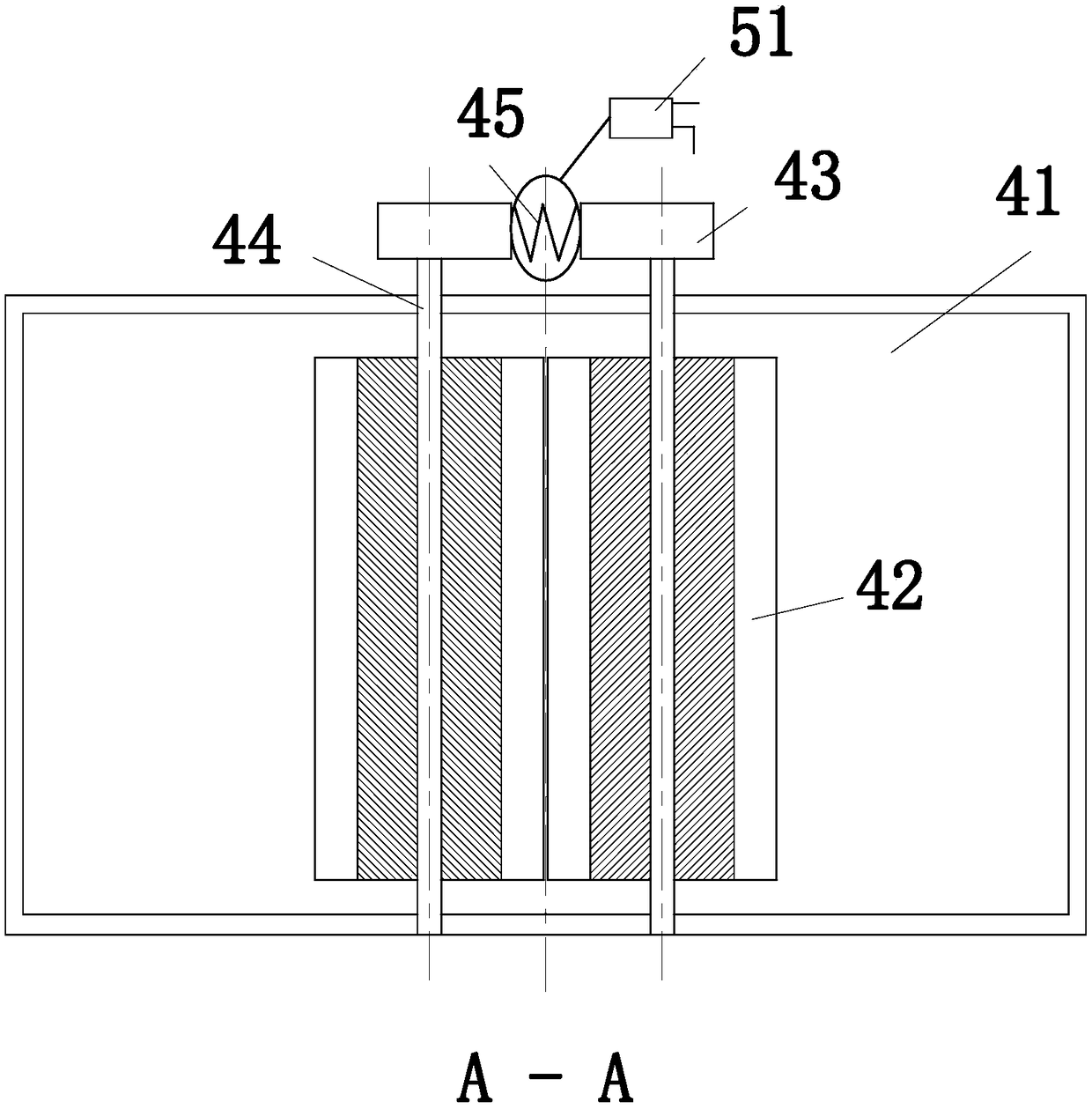

[0035] As an embodiment of the present invention, the grinding unit 3 includes a No. 1 motor 31, an upper fixing rod 32, an adjustment module 33, an upper grinding sheet 34, an upper grinding sheet pressing plate 35, a transmission module 36, a lower grinding sheet 37, Lower fixed rod 38 and motor No. 2 39; Described No. 1 motor 31 is positioned at the upper fixed rod 32; Adjusting module 33 is installed at the bottom of described upper fixed rod 32; Described adjusting module 33 is positioned at upper fixed rod 32 and Between the upper grinding sheets 34; the bottom of the adjustment module 33 is fixedly connected with the lower grinding sheet 37; the upper grinding sheet 34 is located below the upper grinding sheet pressing plate 36, and the lower surface of the upper grinding sheet 34 is provided with a downward protrusion arc-shaped protrusions, and the surface of the arc-shaped protrusions is provided with grooves; a transmission module 36 is provided between the upper gri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com