Drill bit for machining aluminum and aluminum alloy

A technology of aluminum alloy and drill bits, which is applied in metal processing equipment, drill repairing, drilling tool accessories, etc., can solve the problems of limited cutting efficiency and low processing quality of high-strength aluminum and aluminum alloys, and achieve simple and practical grinding structure, The effect of increasing the effect and chip removal and reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

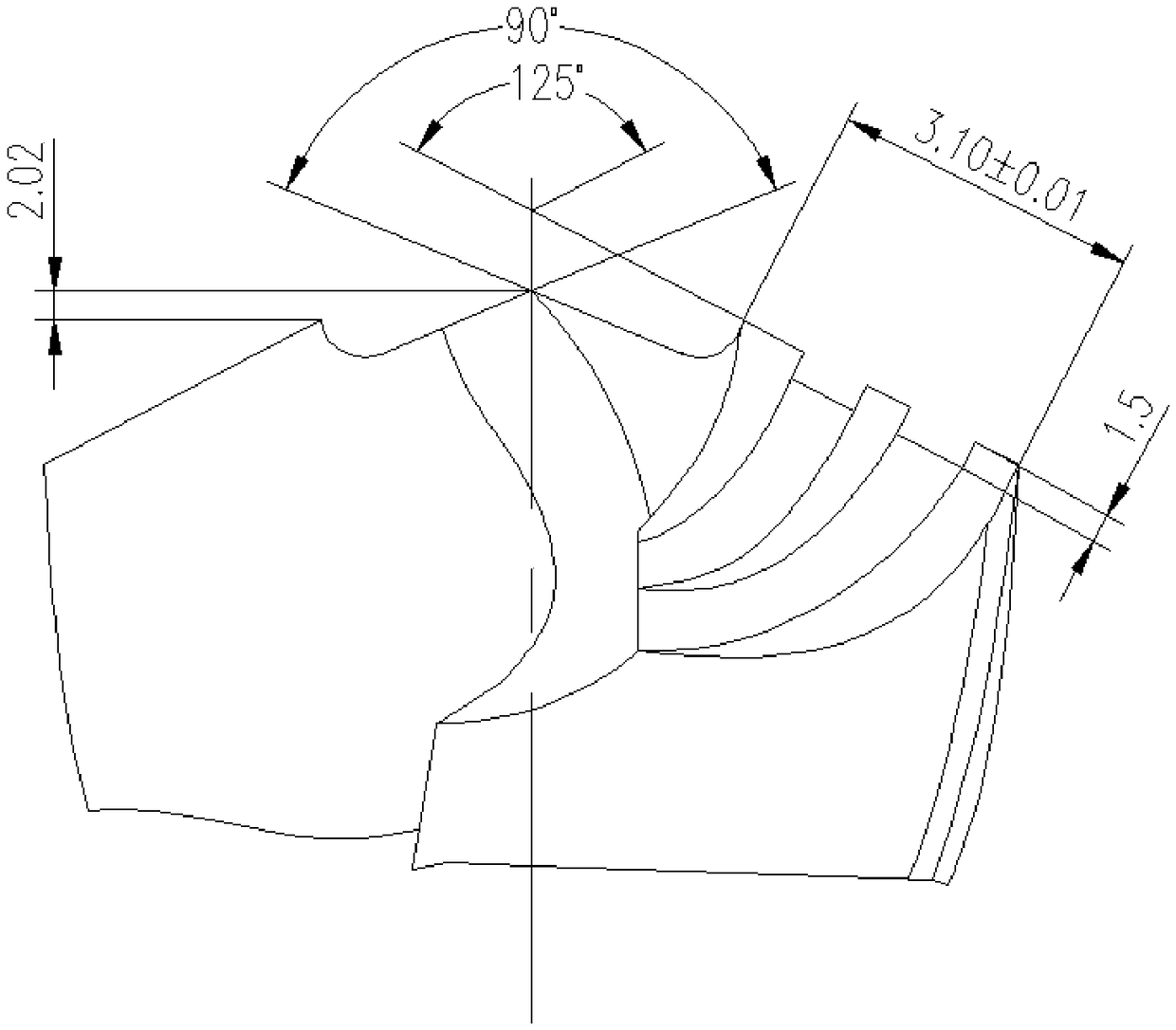

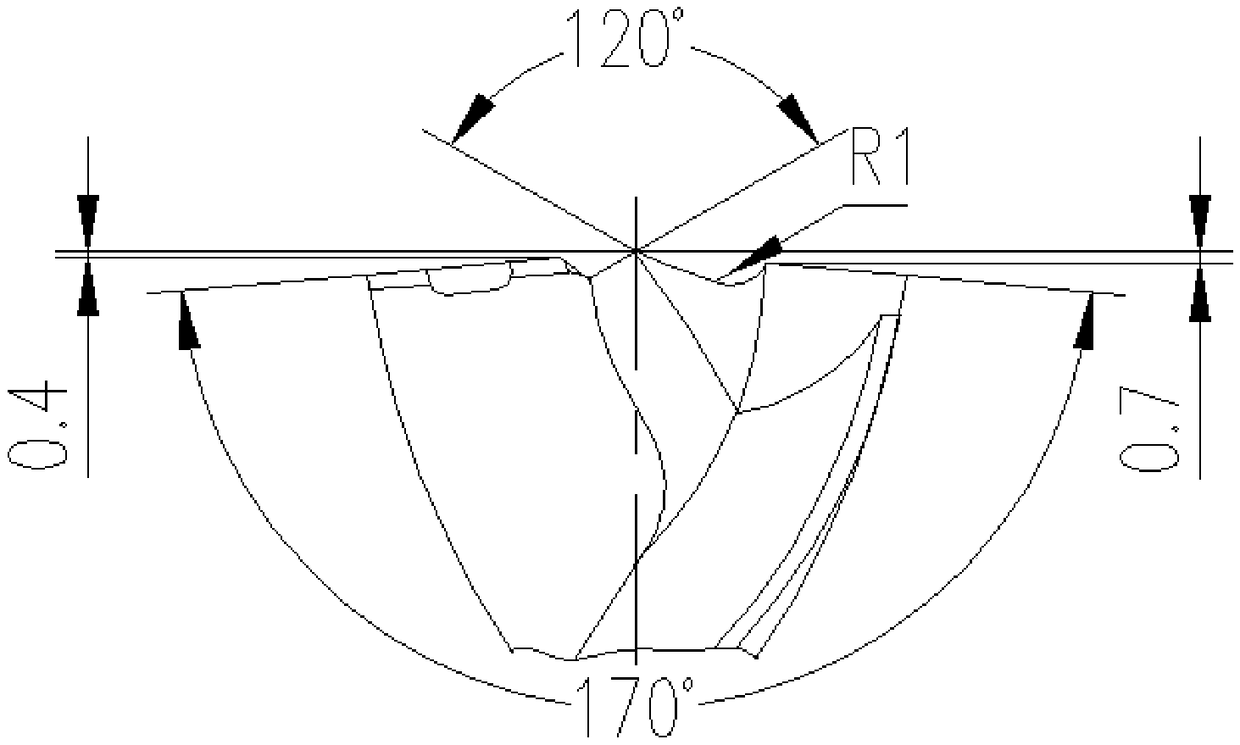

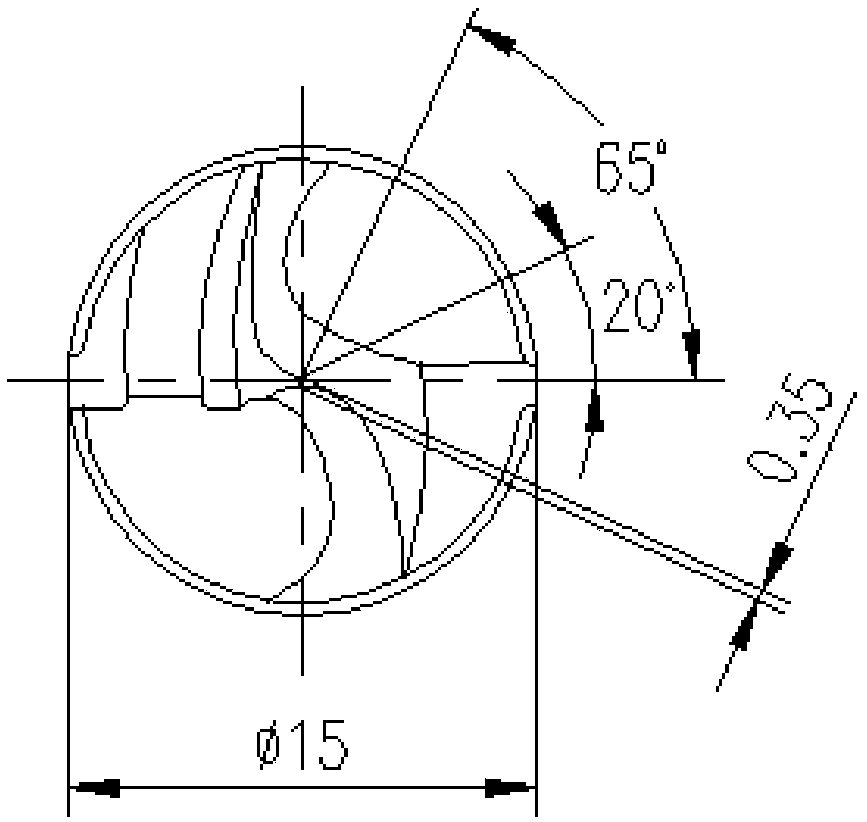

[0018] A kind of drill bit for processing aluminum and aluminum alloy of the present invention belongs to the group drill bit. After a large amount of practical experience, it includes drill bit (chisel edge) tip height h, inner edge angle, length from outer edge to cutting edge, outer edge Angle, chisel edge width, and a series of parameters of back angle arc length are improved, and the following parameters can be obtained to solve the problems in the prior art.

[0019] The drill bit (chisel edge) point height h = 2.02mm, and the inner edge angle is 90°.

[0020] Increase the facet of the outer edge, the facet angle is 3, and the width of the facet is 2.7mm-2.9mm;

[0021] The small plane is processed near the outer edge of the main back, the small plane passes through the outer edge, the angle between the small plane and the chip plane (horizontal plane) is 3 degrees, and the small plane borders the main back, (the junction is approximately parallel to the outer edge ,) T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com