Rocket-type rotating detonation/ramjet combined engine

An engine and rocket-type technology, applied in the field of combined engines, can solve the problems of small size of combined engines, low inflow pressure, unstable combustion, etc., and achieve the effects of improved endurance, simple structure, and large shear contact surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings, that is, the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

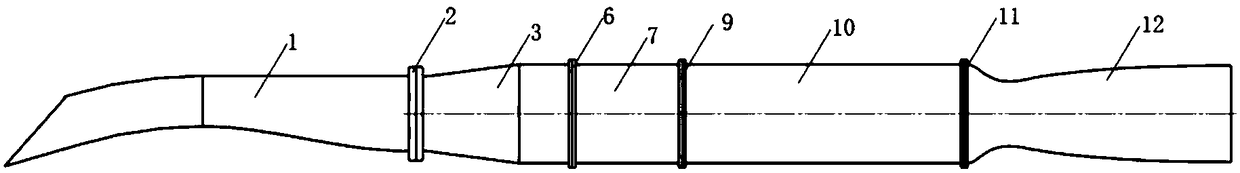

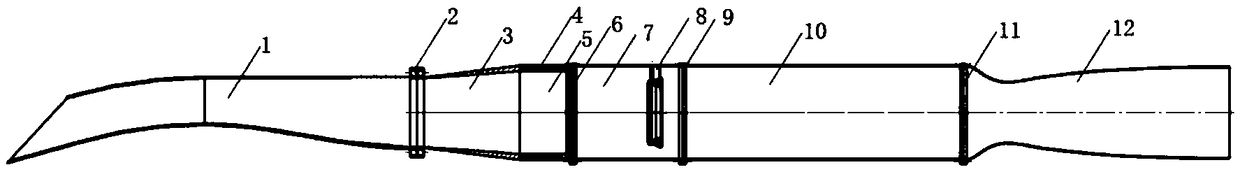

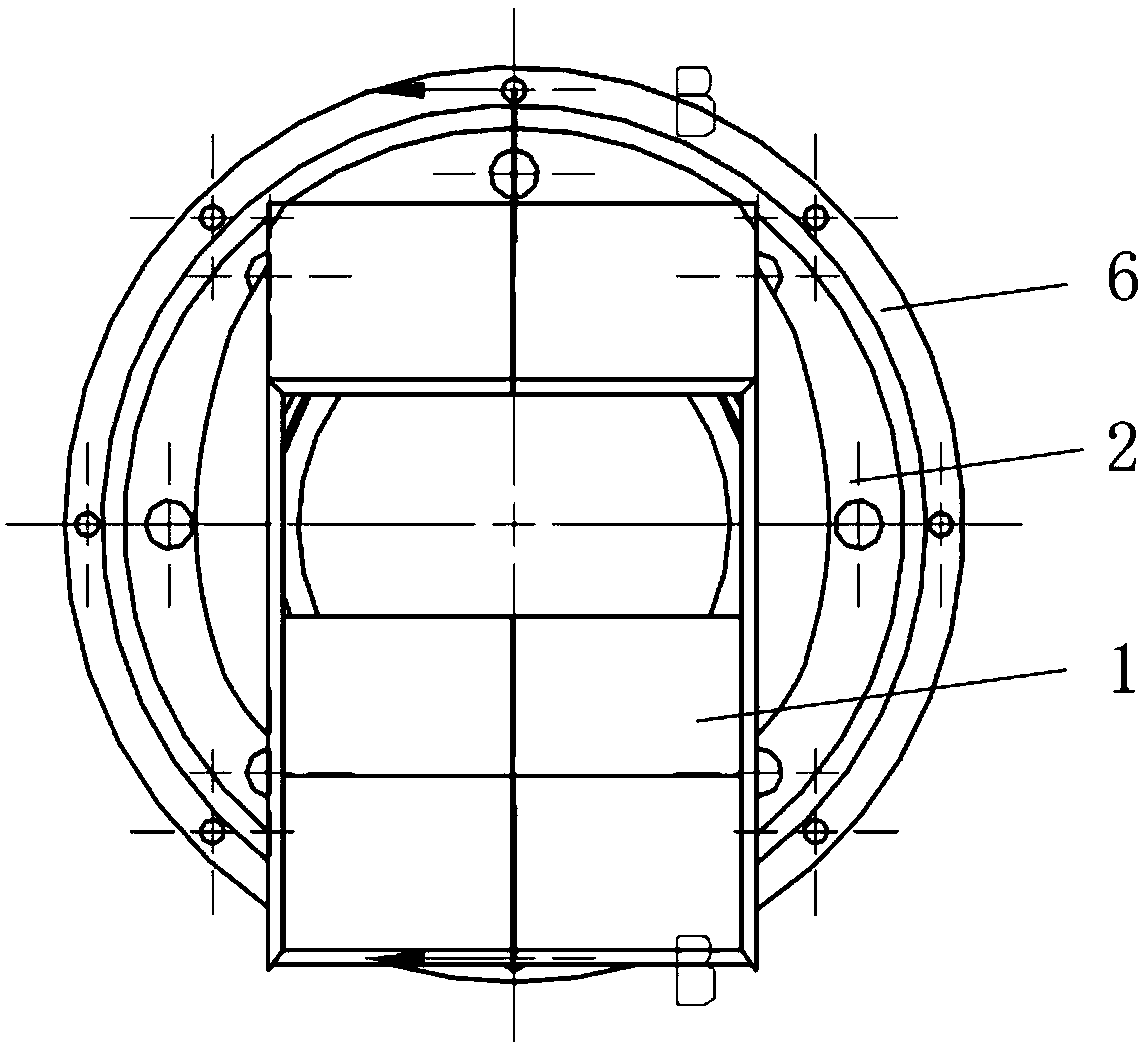

[0028] Such as Figure 1~6 As shown, the embodiment of the present invention is composed of an air inlet 1 , an expansion section 3 , a rotary detonation rocket 4 , a mixing section 7 , a flame stabilizer 8 , a ram combustion chamber 10 and a tail nozzle 12 . The intake passage 1, the expansion section 3, the mixing section 7, the ram combustion chamber 10 and the tail nozzle 12 are sequentially connected, and the intake passage 1 and the expansion section 3, the expansion section 3 and the mixing section 7, the mixing section 7 and the ram The combustion chamber 10, the ram combustion chamber 10 and the tail nozzle 12 are respectively connected by connecting piece 1 2, connecting piec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com