Hydraulic driving device for large reel type sprinkler

A drive device, reel-type technology, applied in the direction of fluid pressure actuators, mechanical equipment, servo motors, etc., can solve the problems of cumbersome mechanical transmission mechanisms, large machine volume, unfavorable maintenance, etc., to overcome the driving force of water turbines Insufficient, eliminate recovery speed error, optimize the effect of maintenance process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

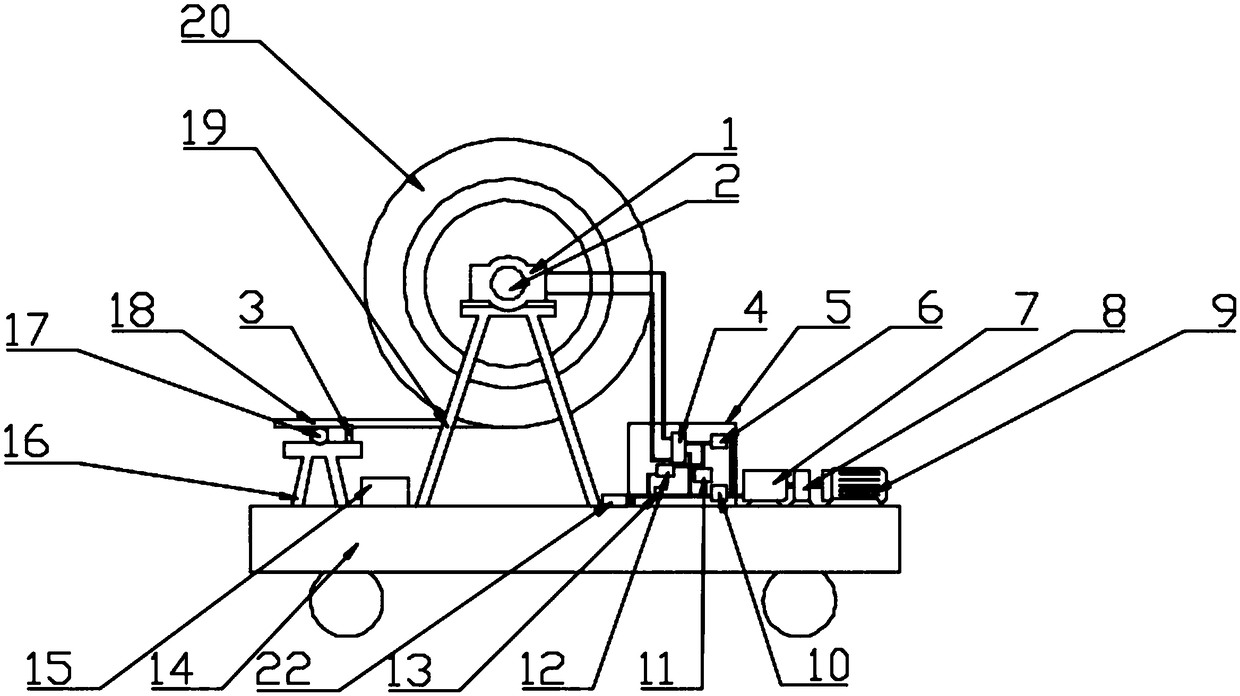

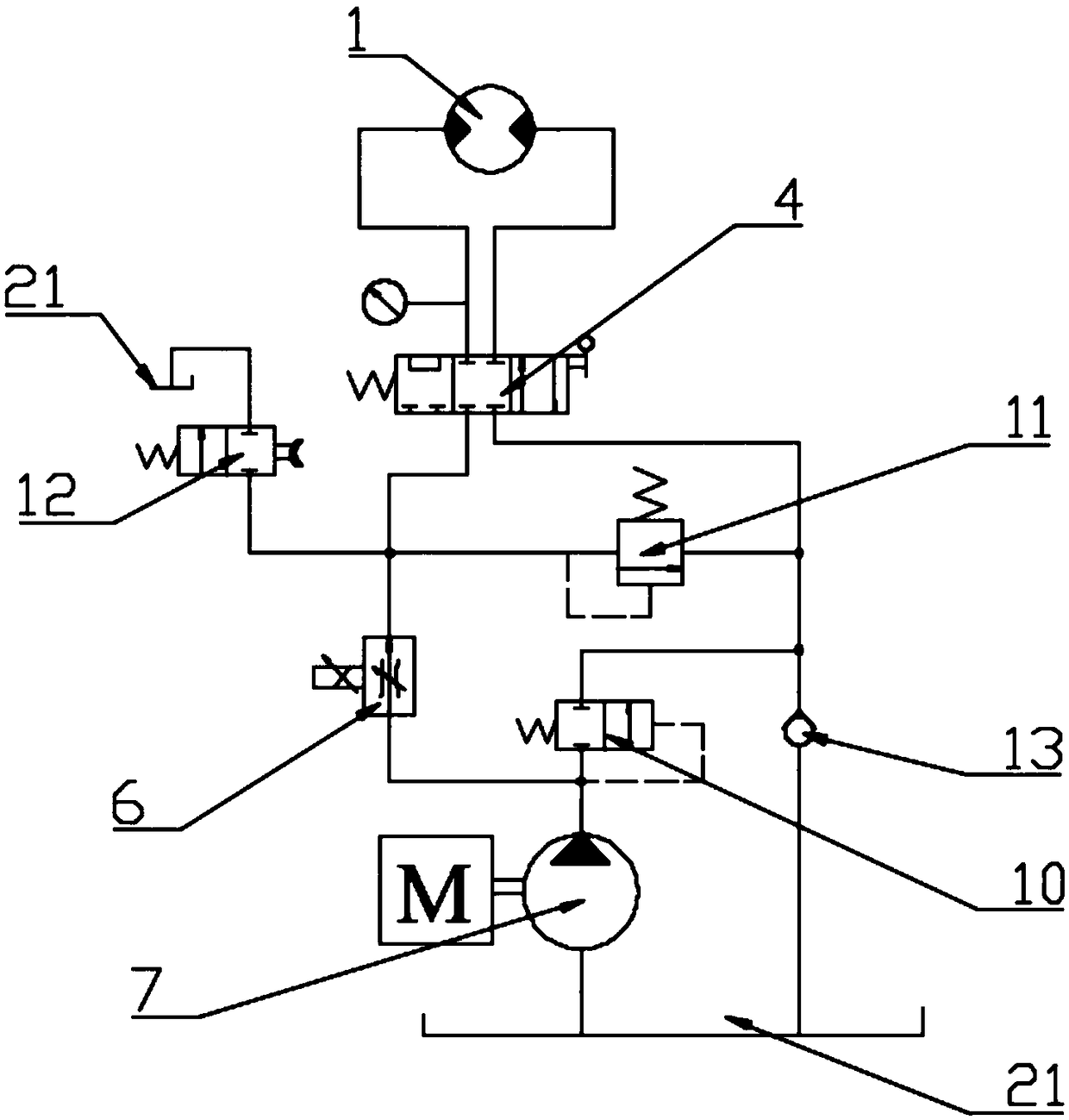

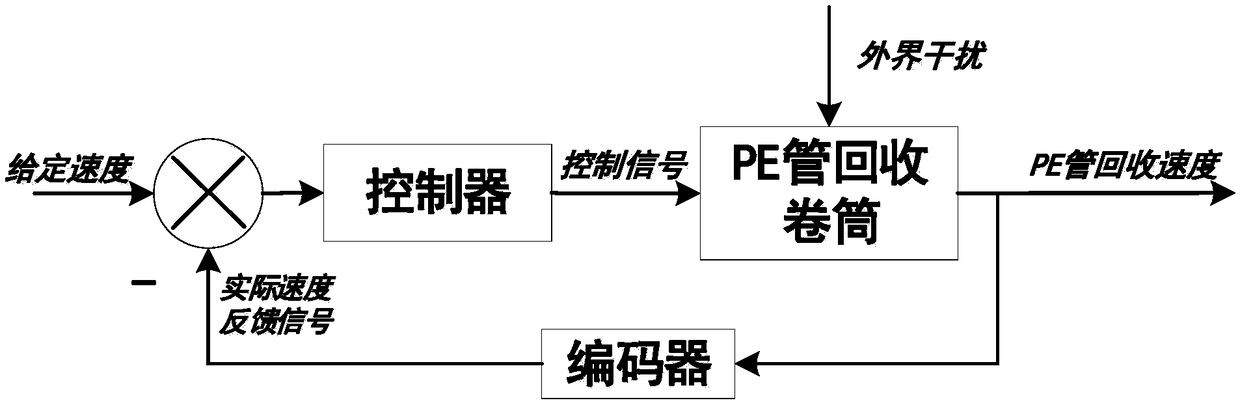

[0022] Such as Figure 1 to Figure 3 As shown, a large-scale reel-type sprinkler hydraulic drive device includes a reel 20 and a PE pipe 18. The reel 20 is supported on the vehicle body 14 of the irrigation machine through a reel support frame 19, and the PE pipe 18 is rotatably wound on the reel On the disk 20, the drive mechanism is connected with the reel shaft and drives the rotation of the reel 20; the drive mechanism includes a hydraulic motor 1 and a hydraulic system, the hydraulic motor 1 is installed on the reel support frame 19, and the output shaft of the hydraulic motor 1 passes through The coupling 2 is connected with the reel shaft; the hydraulic system includes a hydraulic pump 7, a hydraulic valve block 5 and a hydraulic pump driving device, the hydraulic valve block 5 is fixed on the vehicle body 14, and a three-position four...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com