Three-dimensional shape sensing measurement method and device based on multi-core fibers

A multi-core fiber, three-dimensional shape technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

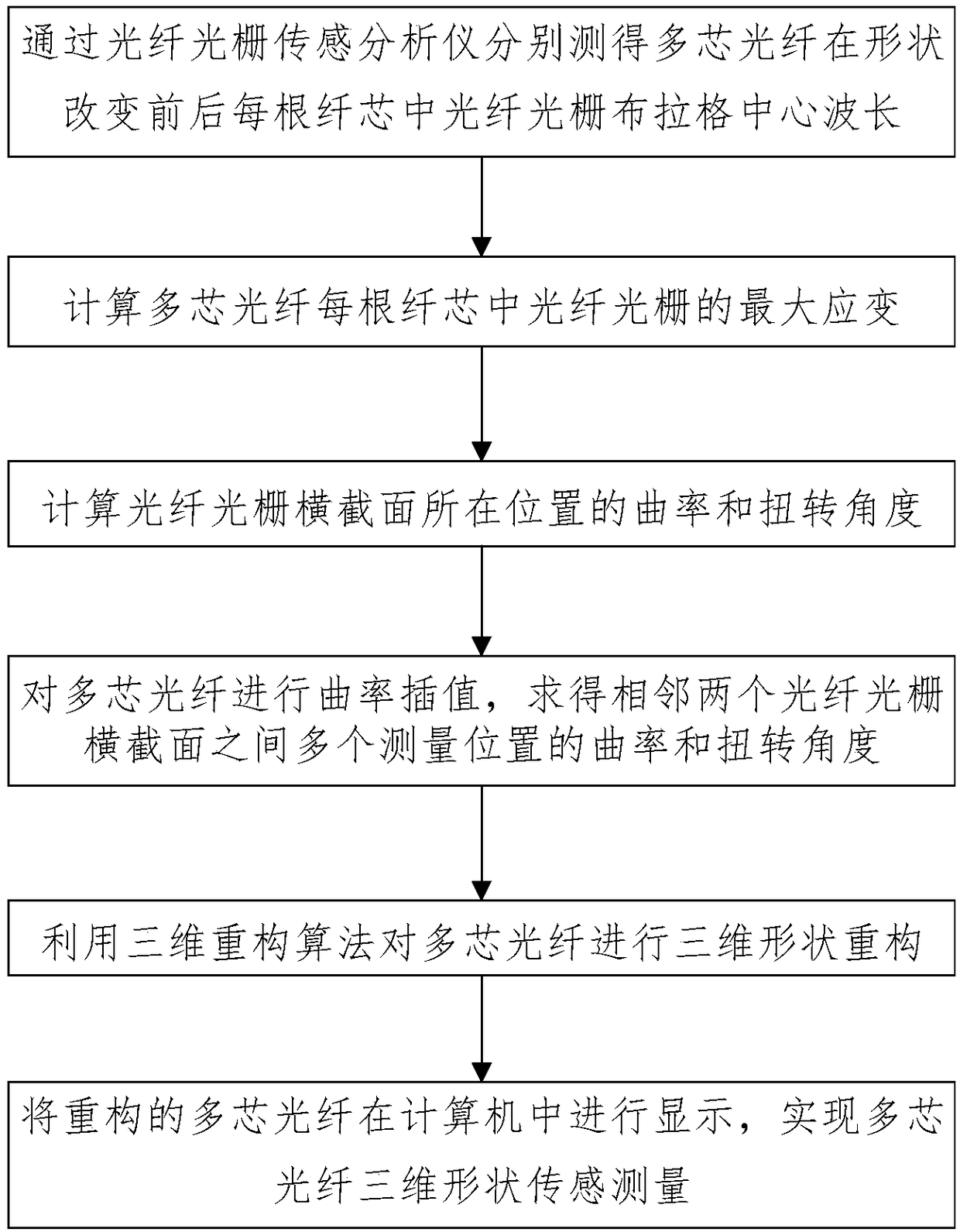

Method used

Image

Examples

Embodiment

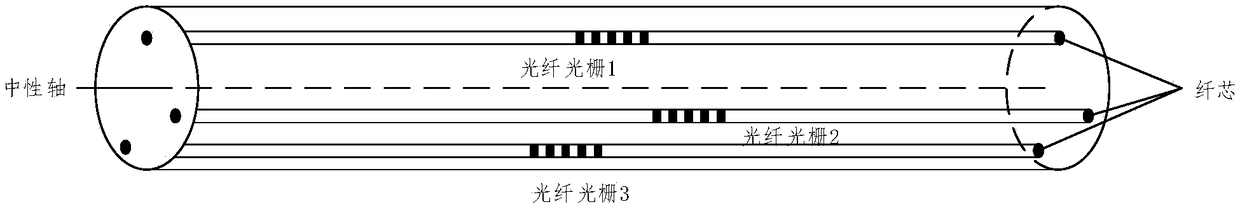

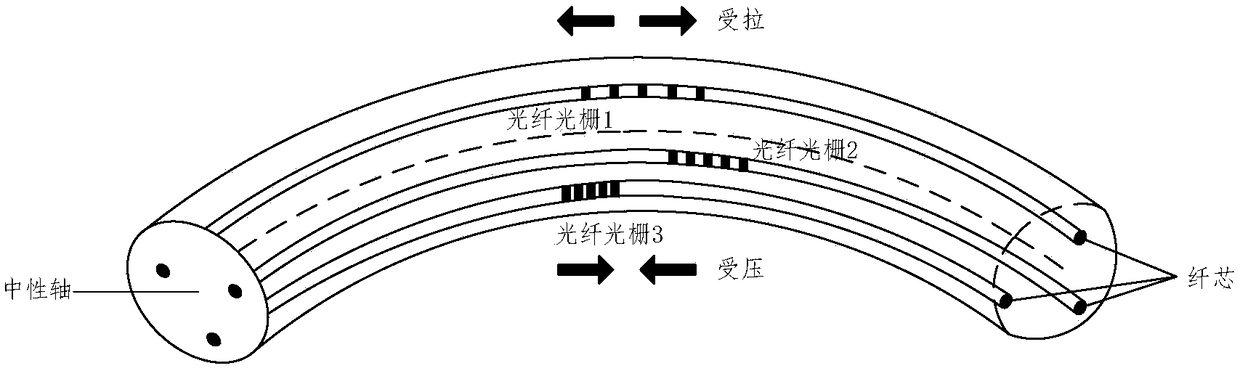

[0070] Embodiment: The three cores of the three-core optical fiber symmetrically distributed are connected to the three channels of the fiber grating sensor analyzer using FC-type optical fiber connectors. The probe light from the analyzer enters the three-core fiber through the three-core fiber fan-in and fan-out module. First fix the three-core optical fiber along the diagonal of the paper, preferably on the diagonal of the 21cm×29.7cm paper, make the three-core optical fiber in a straight state for testing, and store the three-core optical fiber before the shape changes Fiber grating Bragg center wavelength in each fiber core; Then the paper that is fixed with three-core optical fiber is rolled into cylinder shape, preferably, cylinder diameter 6.8cm, as Figure 7 As shown, the three-core optical fiber is tested when it is in a helical state. The fiber grating sensor analyzer measures that the center wavelength of the fiber grating Bragg in each core of the three-core optic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com