Outer building wall crack detection system and method based on machine vision

A technology for building exterior walls and machine vision, used in instruments, measuring devices, scientific instruments, etc., can solve problems such as large amount of calculation, undisclosed image processing detection methods, and reduced accuracy of kinect depth sensors, so as to improve detection efficiency and reduce The effect of small personal safety risk, improving detection efficiency and detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

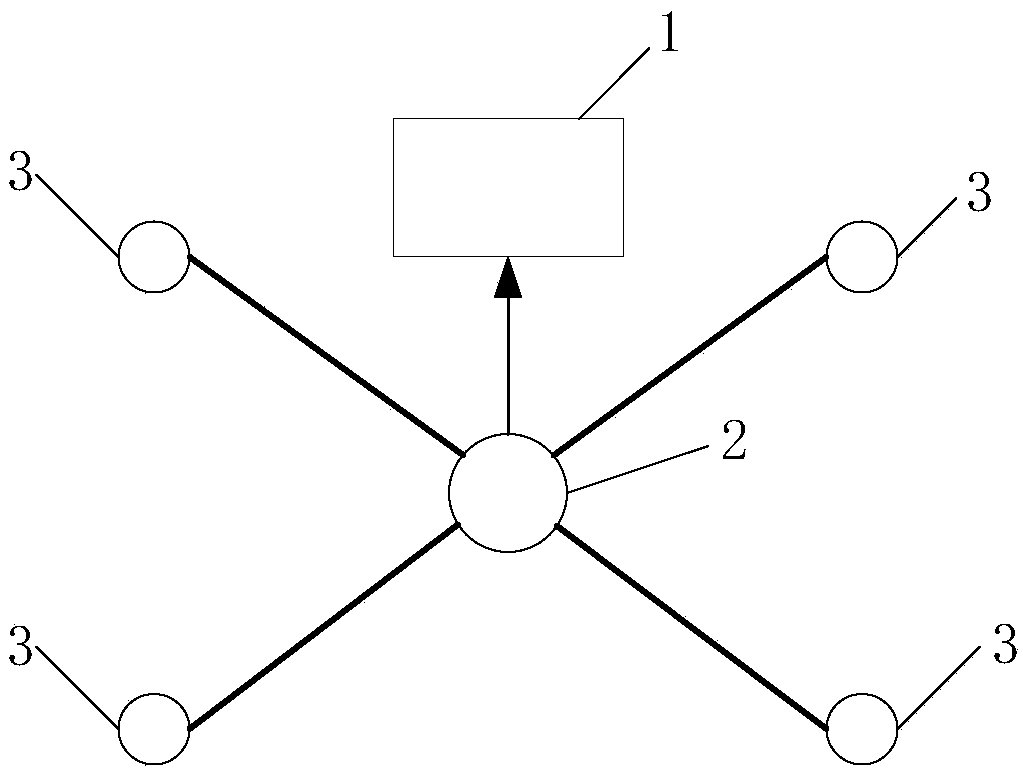

[0036] as attached figure 1As shown, a machine vision-based building exterior wall crack detection system includes a microcomputer processor 1, a CMOS sensor 2 and a laser lighting system 3, the microcomputer processor 1 and the CMOS sensor 2 are connected through a USB interface, and the CMOS sensor 2 and the laser lighting system System 3 is fixedly connected through structural members.

[0037] Microcomputer processor 1 includes core components such as CPU, GPU, memory, and flash memory. Among them, CPU is a quad-core ARM Cortex-A57 processor, GPU is Nvidia Pascal architecture, 256CUDA core, memory is 8GB LPDDR4, flash memory is 32GBeMMC, and runs Linux Ubuntu 16.04 The operating system collects images obtained by the CMOS sensor 2 through USB2.0.

[0038] The laser lighting system 3 includes four point-shaped laser emitters arranged in a rectangle, which can emit four bright laser spots; The center is located at the imaging center of the CMOS sensor 2 .

[0039] The CMO...

Embodiment 2

[0042] as attached figure 1 As shown, based on the above-mentioned embodiment 1, the difference of this embodiment is that the CMOS sensor 2 can collect color images of three channels of red, green and blue, the image resolution is 1280*720 pixels, and the acquisition frame rate is 25 frames per second. Equipped with an 8mm fixed-focus lens, the internal parameter matrix and distortion coefficient of the sensor are obtained through a calibration algorithm before use.

[0043] The laser lighting system 3 is composed of four point-shaped laser emitters arranged in a rectangle, the long side L of the rectangle is 16mm, the short side W is 9mm, the laser wavelength is 710nm, and the power is 2mW. The emitted beam is perpendicular to the imaging plane of the CMOS sensor 2. The center of the rectangle is located at the imaging center of the CMOS sensor 2, and at a distance of 1m, the spot diameter is 2mm; the laser lighting system 3 is fixedly connected to the CMOS sensor 2 through ...

Embodiment 3

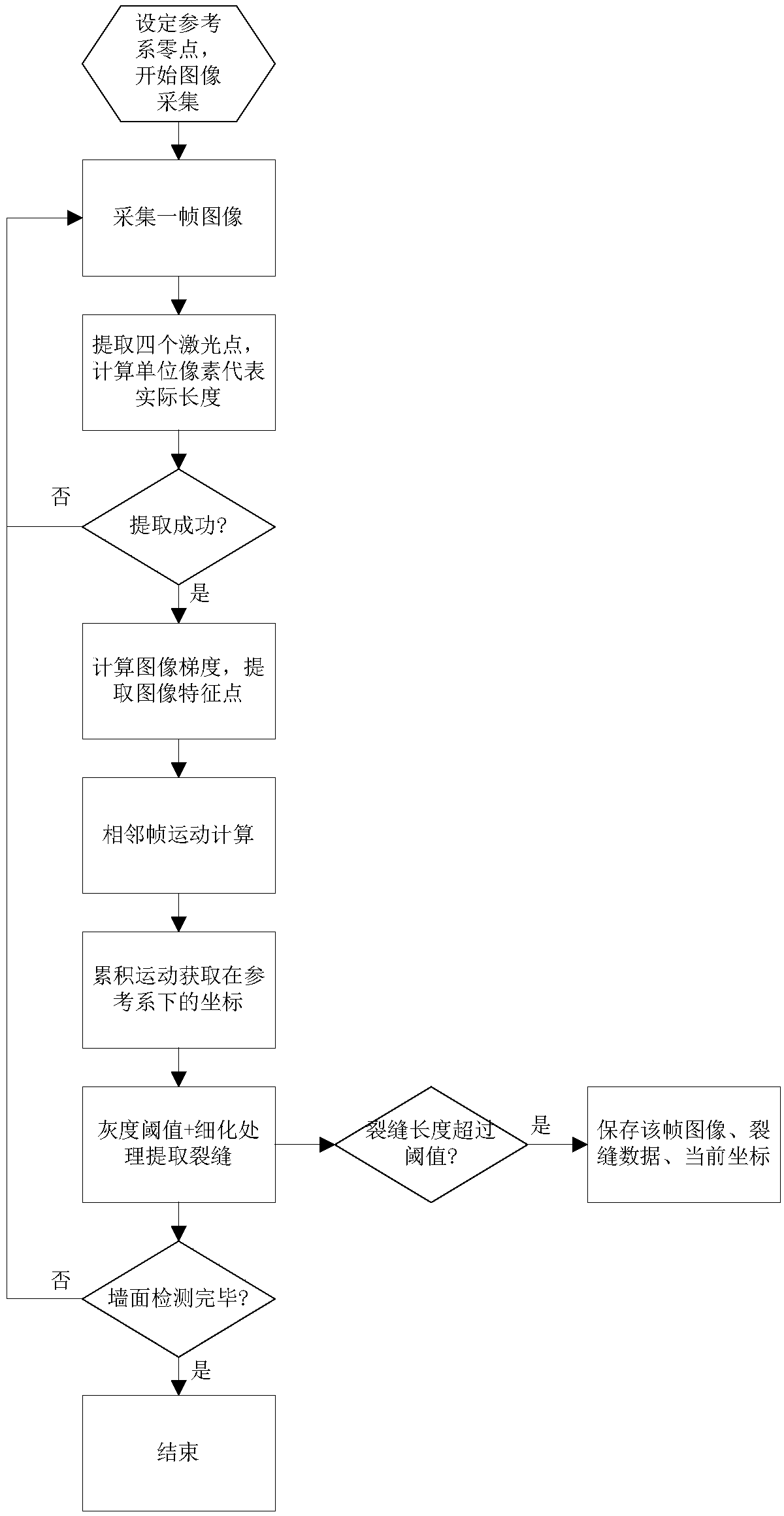

[0047] Based on the foregoing embodiments, a detection method of a machine vision-based building exterior wall crack detection system comprises the following steps:

[0048] (1) Place the CMOS sensor 2 and the laser lighting system 3 parallel to the wall, the longitudinal axis of the imaging plane of the CMOS sensor 2 is vertically downward, and the distance between the CMOS sensor 2 and the outer wall is within 1m, start image acquisition, and ensure four The laser dot is visible within the image;

[0049] (2) Red threshold processing is carried out to image on microcomputer processor 1, extracts four brightest red spots, verifies four vertices that four points form a rectangle, calculates the length Lp and width Wp (in pixels) of rectangle , and then calculate the actual length s=(L+W) / (Lp+Wp) represented by the image unit pixel;

[0050] (3) Taking the current position as the zero point of the building exterior wall reference system, the gradient calculation is carried out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com