In-service long-distance transport pipeline girth-weld defect magnetic-particle detection mechanism and detection method

A detection mechanism, magnetic particle detection technology, applied in the direction of material magnetic variables, etc., can solve the problems of unsatisfactory production and operation, low detection rate and recognition rate, etc., achieve fast detection speed, increase detection rate and recognition rate, and easy to use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

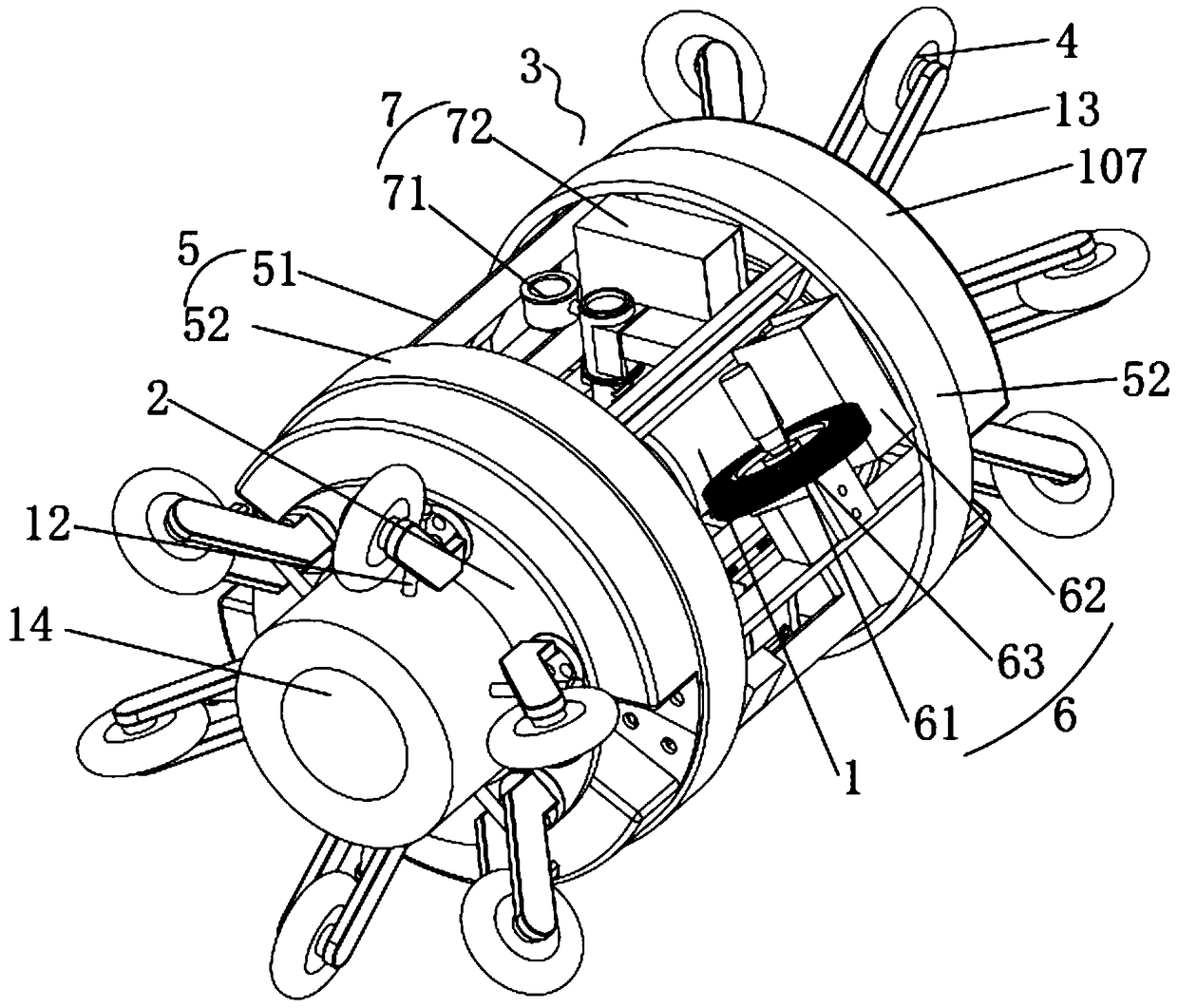

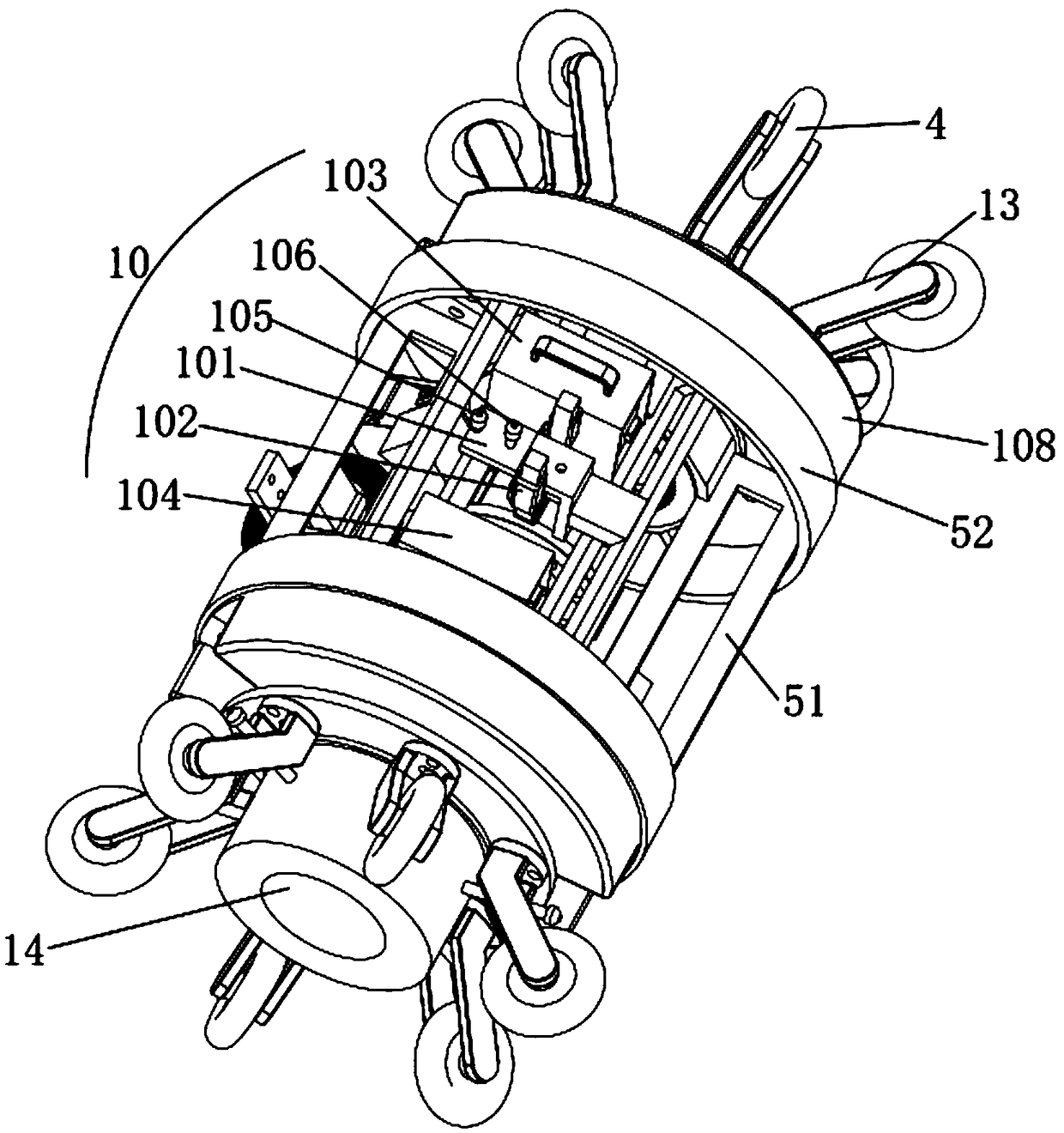

[0039] Figure 1 to Figure 5 Shown is an in-service long-distance pipeline ring weld defect internal magnetic particle detection mechanism provided by the present invention, including a central tube 1, fixed seats 2 fixedly sleeved at both ends of the central tube 1 and rotatably sleeved on the central tube 1 Rotating mechanism 3 at two ends; Walking wheels 4 are installed on the two fixed seats 2; Mounting frame 5 is also connected between the two rotating mechanisms 3, and cleaning devices are installed at even intervals in the circumferential direction of the mounting frame 5 6. High-definition visual acquisition device 7. Automatic magnetic particle detection device 10; the head of the central tube 1 is also fixedly equipped with a welding seam identification probe 12.

[0040] The central tube 1 is a hollow t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com