Device and method for denitration of carbon electrode open-type baking furnace combustion zone

A roasting furnace and open technology, which is applied in the field of carbon electrode roasting production, can solve the problems of restricting denitration treatment, difficult to control temperature fluctuation, etc., and achieve the effects of high risk, simple installation and stable furnace temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The following will further explain the present invention in conjunction with the accompanying drawings, which are only used for explaining the present invention rather than limiting it.

[0047] The denitration agent referred to in the present invention is a special product for carbon electrode open roasting furnaces.

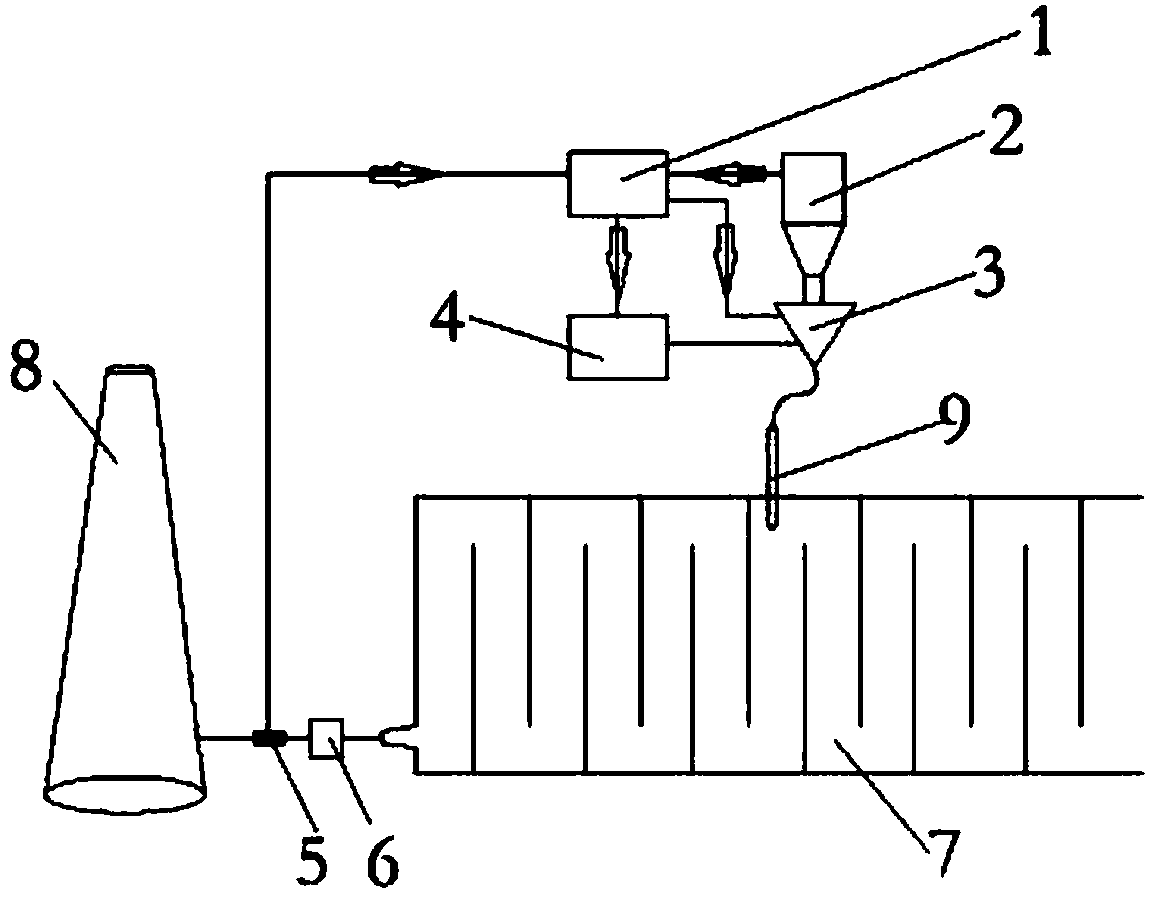

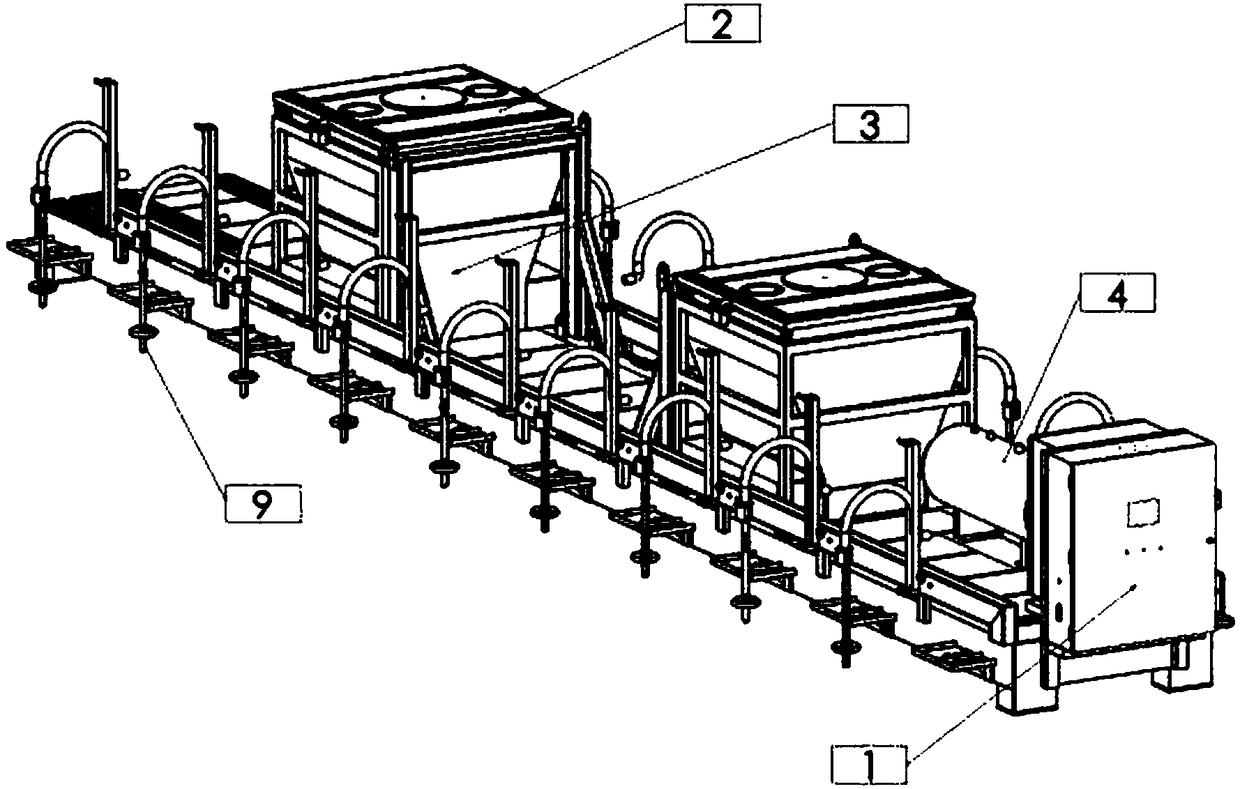

[0048] See figure 1 , The denitrification device provided by the present invention includes: a denitrification agent silo 2, a feeding device 3, a compressed air conditioning station 4, an online flue gas monitoring device and a spray gun.

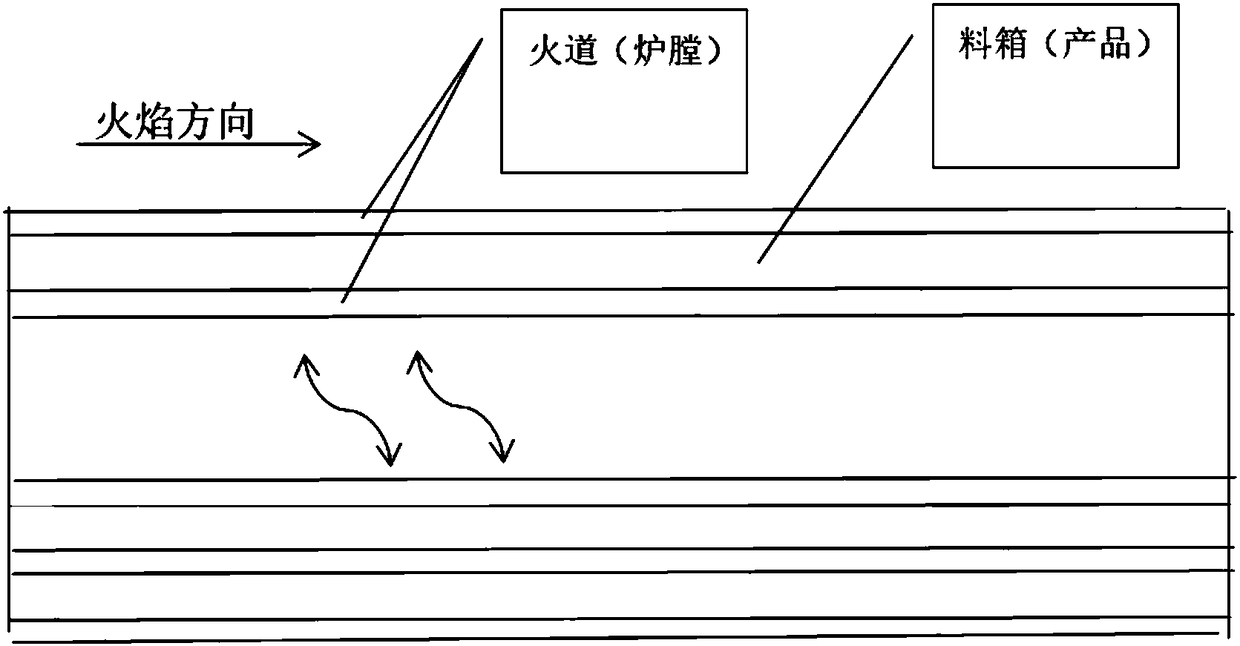

[0049] The denitration agent silo 2 is connected to a precision feeding device 3, and the feeding device 3 is connected to a spray gun 9 through a pipeline, and the spray gun 9 is inserted into an open roasting furnace. The spray gun should be inserted into a suitable position in the open roasting furnace, and the suitable position is not a fixed position, which should be adjusted according to the change of the dyn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com