Reverse osmosis device for processing industrial sewage with high salt concentration

A technology of reverse osmosis device and reverse osmosis membrane, which is applied in the field of reverse osmosis, can solve the problems of low hydrothermal stability of organic membrane, high maintenance cost of reverse osmosis device, low salt rejection rate and flux, etc., so as to improve water purification High water yield, increased water flux, and less fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

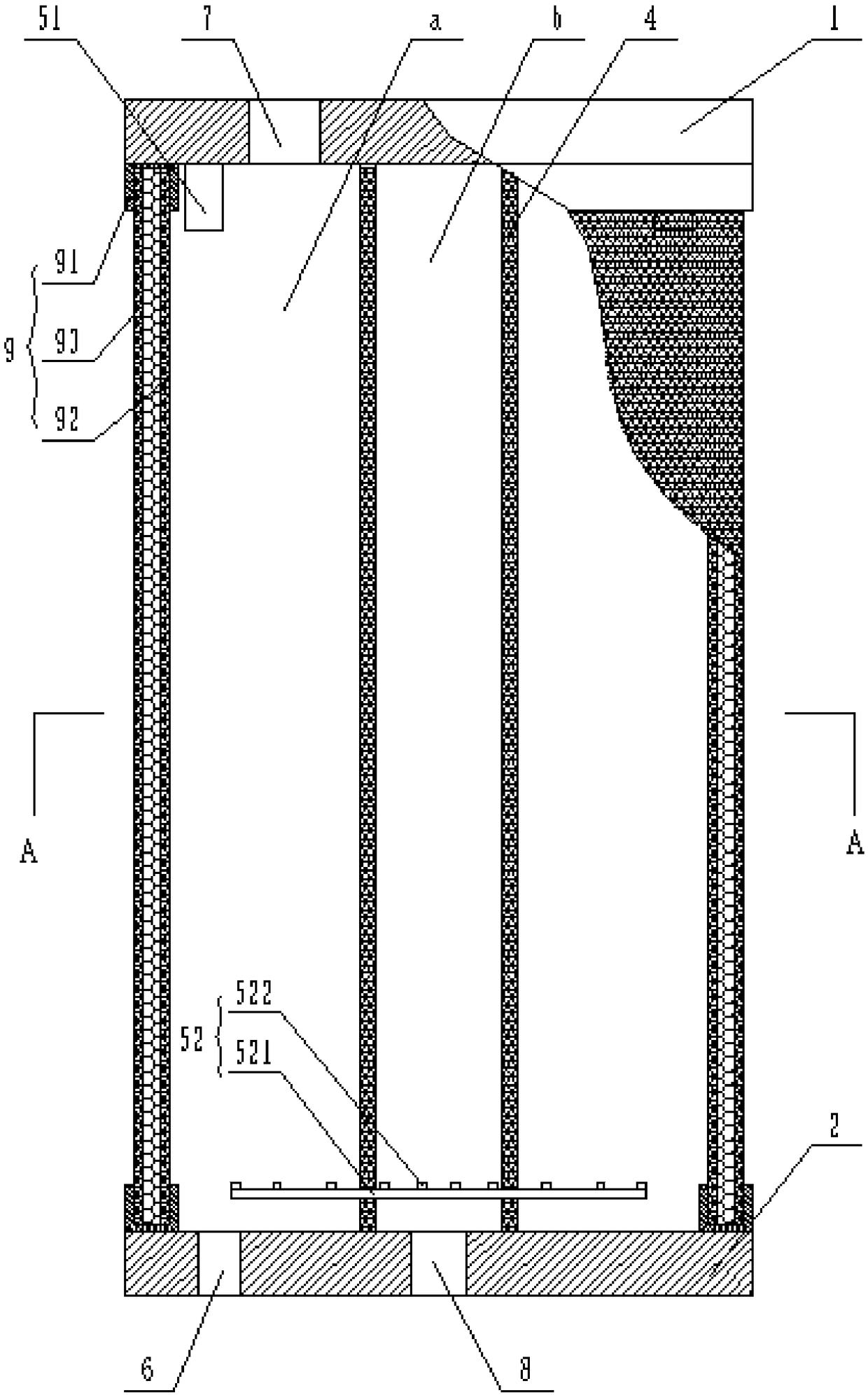

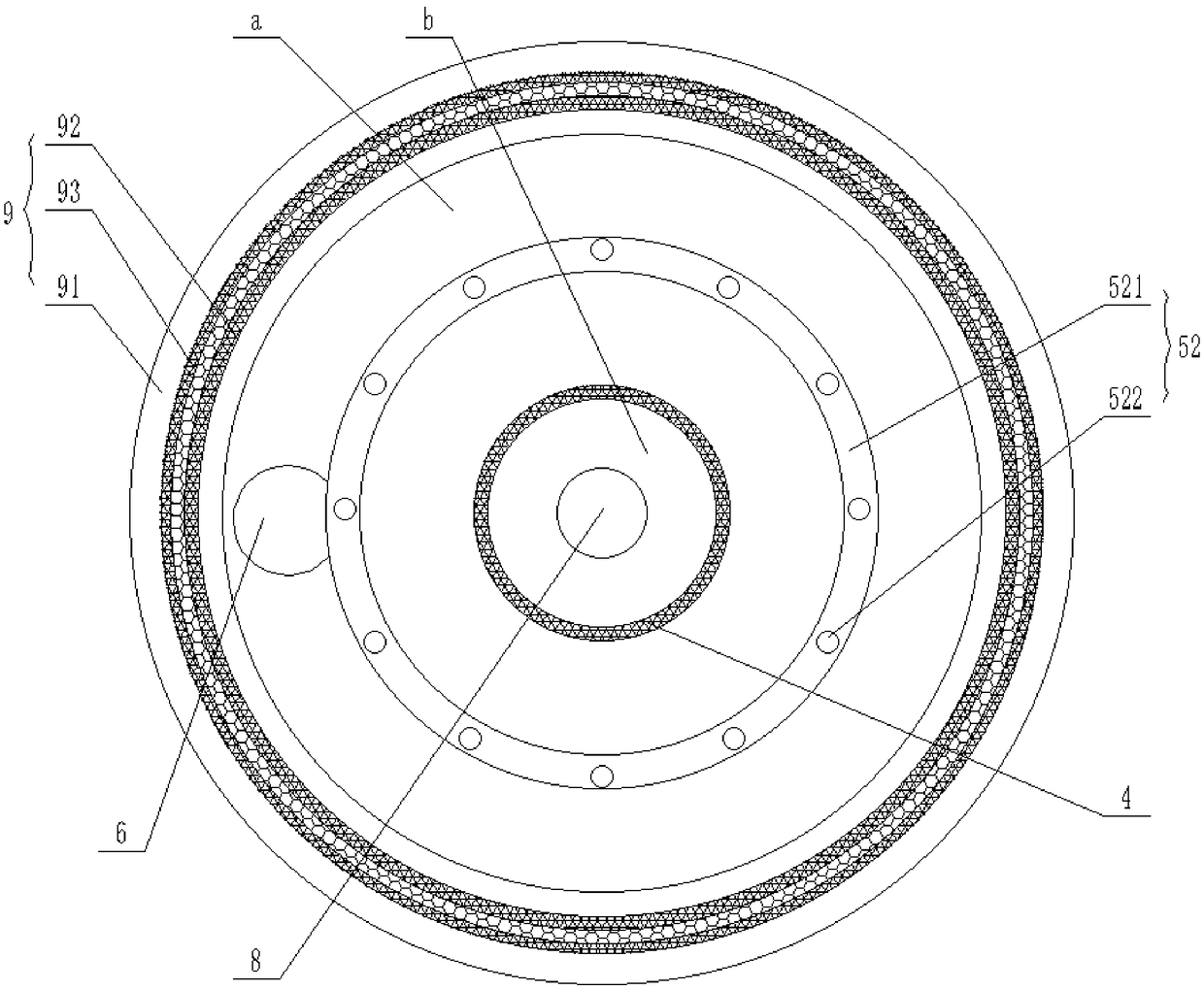

[0021] Embodiment 1 handles the reverse osmosis device I of industrial concentrated salt sewage

[0022] Such as Figure 1-2 As shown, a reverse osmosis device for treating industrial concentrated salt sewage includes an upper mounting seat 1 and a lower mounting seat 2 facing oppositely, and a reverse osmosis membrane 1 is arranged between the upper mounting seat 1 and the lower mounting seat 2. Between the upper mounting base 1, the lower mounting base 2 and the reverse osmosis membrane 1, a liquid holding area is formed, and a filter cartridge 4 is vertically arranged in the liquid holding area, and the filter cartridge 4 is a stainless steel filter screen. The upper and lower ends of the filter cartridge 4 are fixedly connected to the lower surface of the upper mount 1 and the upper surface of the lower mount 2 respectively, the pore size of the stainless steel filter is less than 100 μm, and the filter cartridge 4 holds the solution The area is divided into an outer perm...

Embodiment 2

[0033] Example 2 Reverse Osmosis Device II for Treating Industrial Concentrated Salt Sewage

[0034] Such as Figure 1-2 As shown, a reverse osmosis device for treating industrial concentrated salt sewage includes an upper mounting base 1 and a lower mounting base 2 facing each other, and a reverse osmosis membrane II is arranged between the upper mounting base 1 and the lower mounting base 2. The upper mounting seat 1, the lower mounting seat 2 and the reverse osmosis membrane II are surrounded by a liquid holding area, and a filter cartridge 4 is vertically arranged in the liquid holding area, and the filter cartridge 4 is a stainless steel filter screen. The upper and lower ends of the filter cartridge 4 are fixedly connected to the lower surface of the upper mount 1 and the upper surface of the lower mount 2 respectively, the pore size of the stainless steel filter is less than 100 μm, and the filter cartridge 4 holds the solution The area is divided into an outer permeat...

Embodiment 3

[0045] Example 3 Reverse Osmosis Device III for Treating Industrial Concentrated Salt Sewage

[0046] Such as Figure 1-2 As shown, a reverse osmosis device for treating industrial concentrated salt sewage includes an upper mounting base 1 and a lower mounting base 2 facing each other, and a reverse osmosis membrane III is arranged between the upper mounting base 1 and the lower mounting base 2. The upper mounting seat 1, the lower mounting seat 2 and the reverse osmosis membrane III are surrounded by a liquid holding area, and a filter cartridge 4 is vertically arranged in the liquid holding area, and the filter cartridge 4 is a stainless steel filter screen. The upper and lower ends of the filter cartridge 4 are fixedly connected to the lower surface of the upper mounting base 1 and the upper surface of the lower mounting base 2 respectively, the pore size of the stainless steel filter screen is less than 100 μm, and the filter cartridge 4 holds the solution The area is div...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com