Hybrid crosslinked dynamic polymer

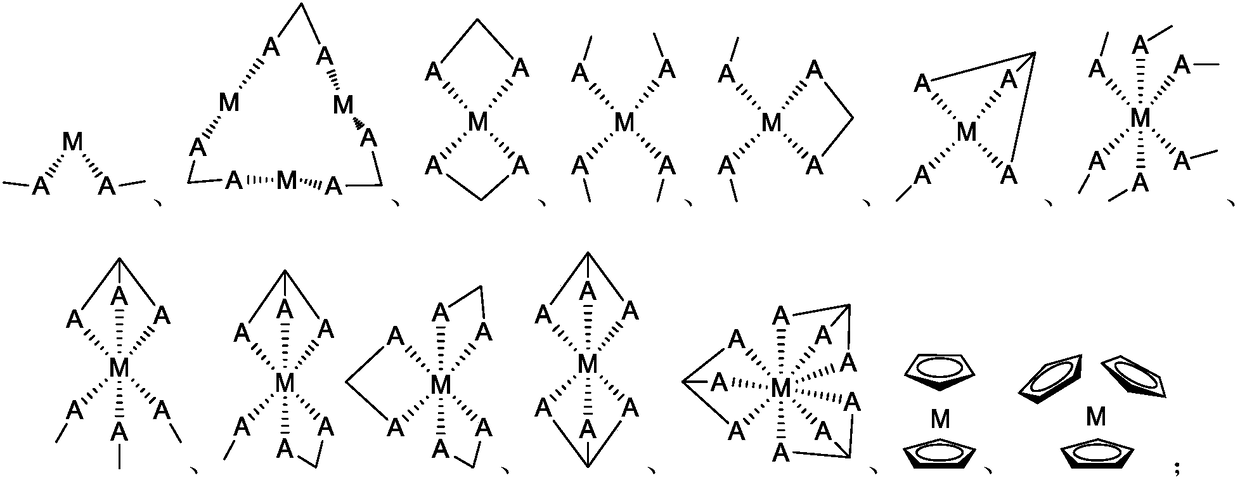

A hybrid cross-linking, polymer technology, applied in the field of smart polymers, can solve problems such as poor mechanical properties, no covalent cross-linked network, and limited application range of dynamic polymers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0191] In the preparation process of dynamic polymer, three methods of mechanical foaming method, physical foaming method and chemical foaming method are mainly used to foam dynamic polymer.

[0192] Among them, the mechanical foaming method is to introduce a large amount of air or other gases into the emulsion, suspension or solution of the polymer with the help of strong stirring during the preparation of the dynamic polymer to make it a uniform foam, and then through physical Or chemical changes make it shape and become a foam material. In order to shorten the molding cycle, air can be introduced and emulsifiers or surfactants can be added.

[0193] Wherein, the physical foaming method is to use physical principles to realize the foaming of the polymer during the preparation of the dynamic polymer, which includes but not limited to the following methods: (1) inert gas foaming method, that is, after adding Press the inert gas into the molten polymer or pasty material under ...

Embodiment 1

[0254] Add 100 parts by mass of toluene, 36 parts by mass of acrylamide, 7.2 parts by mass of 1H,1H,2H-heptafluoropentane-1-ene, 0.1 parts by mass of azobisisobutyronitrile, 0.01 parts by mass of four Methylethylenediamine (TEMED), stir and mix evenly, heat up to 80°C, react for 2 hours, add 24 parts by mass of toluene diisocyanate (TDI), continue to react for 2 hours, remove the solvent, and use deionized water to wash as much as possible, and then The product was put into 100 parts by mass of deionized water and swelled at room temperature for 12 hours to obtain a dynamic polymer hydrogel. It was made into a dumbbell-shaped sample with a size of 80.0×10.0×2.0mm, and a tensile test was carried out using a tensile testing machine. The tensile rate was 50mm / min. The measured tensile strength of the sample was 1.12±0.15MPa, and the elongation at break The rate is 245.21±23.17%, and it can be made into a kind of self-adhesive drug-loaded tough gel material for use.

Embodiment 2

[0256] 1 molar equivalent of polyacrylonitrile (average molecular weight about 10000), 5 molar equivalents of 3-(azidomethyl)pyridine, 10 molar equivalents of 2,5-anhydro-1-azido-1-deoxy-D-glucitol, 3 molar equivalents of methyl azidoacetate, 100 molar equivalents of zinc chloride, a small amount of fumed silicon dioxide and nano-scale iron ferric oxide were dissolved in dimethylformamide, ultrasonicated at room temperature for 5 minutes to fully mix the components and then heated to Stirring and reacting at 125°C to obtain modified polyacrylonitrile product 1; reacting modified polyacrylonitrile product 1 and 1,6-hexamethylene diisocyanate with 0.5 times the molar equivalent of the sum of hydroxyl groups contained in dimethyl sulfoxide to obtain Cross-linked modified polyacrylonitrile product 2; add a DMSO solution containing iron trifluoromethanesulfonate to an appropriate amount of modified polyacrylonitrile product 2, stir evenly and let stand to swell for 12 hours to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com