A laser high temperature shock-nitriding compound processing device and method

A compound processing and nitriding technology, which is applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of low processing efficiency, poor uniformity, and complicated operation, so as to reduce the intermediate process time and facilitate operation , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific implementation examples.

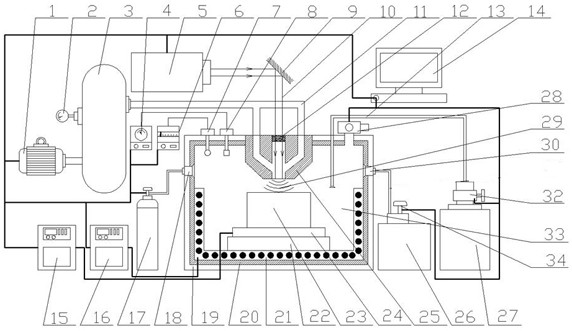

[0018] like figure 1 As shown, a laser high-temperature shock-nitriding composite processing device for improving the fatigue resistance of materials in the present invention includes a laser high-temperature shock system, a nitriding processing system, and a control computer 14 . The laser high temperature impact system includes: air pump 1, pressure gauge 2, pressure accumulator 3, laser 5, reflector 9, gas transmission channel 11, high pressure resistant lens 12, black paint conduit 13, laser head 25, black paint storage tank 27, black paint storage tank electromagnetic valve 32; the inside of the laser head 25 is provided with three passages, the central passage is for the laser beam to pass through, the gas transmission passage 11 on the side of the central passage is used for high-pressure gas to pass through, and the pressure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com