Steel pipe-concrete pile foundation as temporary foundation and construction method thereof

A technology of concrete piles and steel pipes, applied in infrastructure engineering, architecture, bridge construction, etc., can solve the problems of unsuitable flyover bridges, increased construction costs, and large construction work areas, so as to shorten the construction period and reduce waste of resources , The effect of groundwater level is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

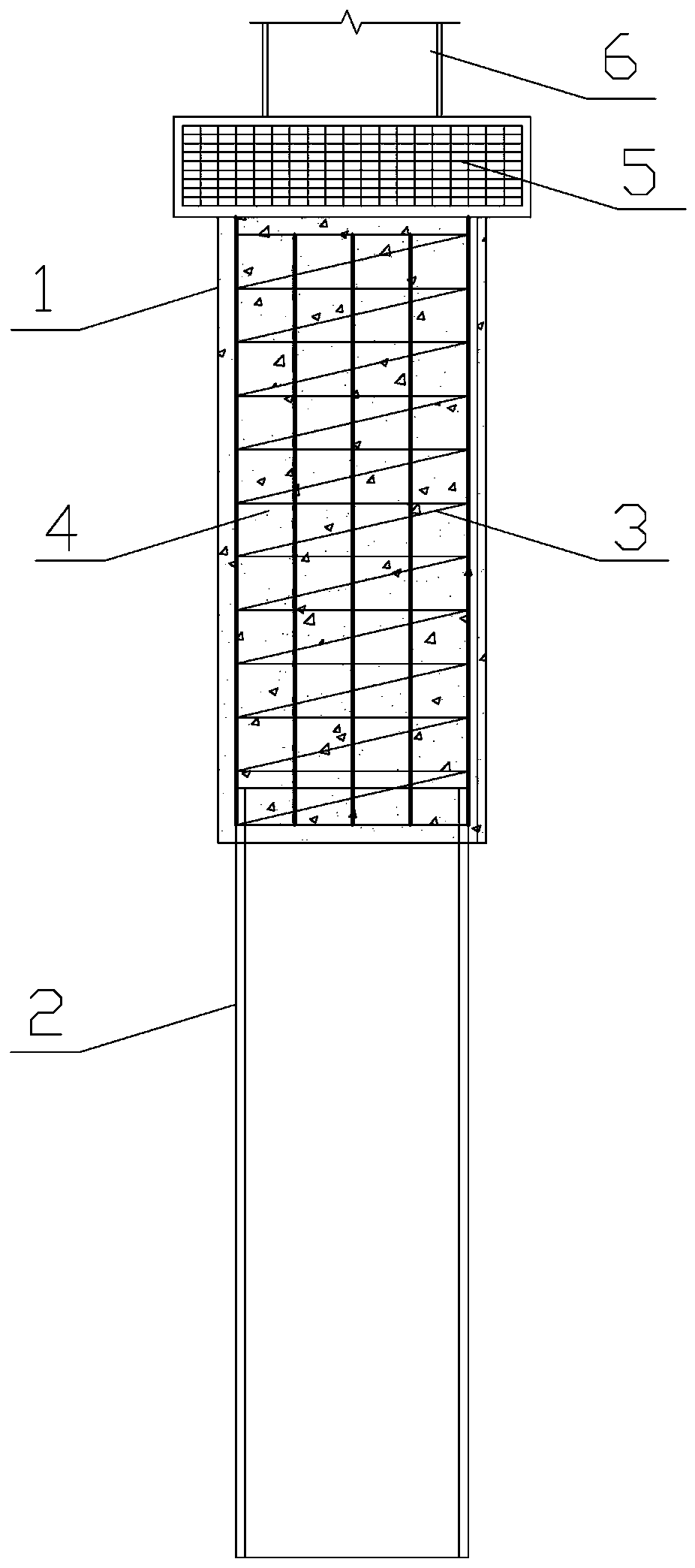

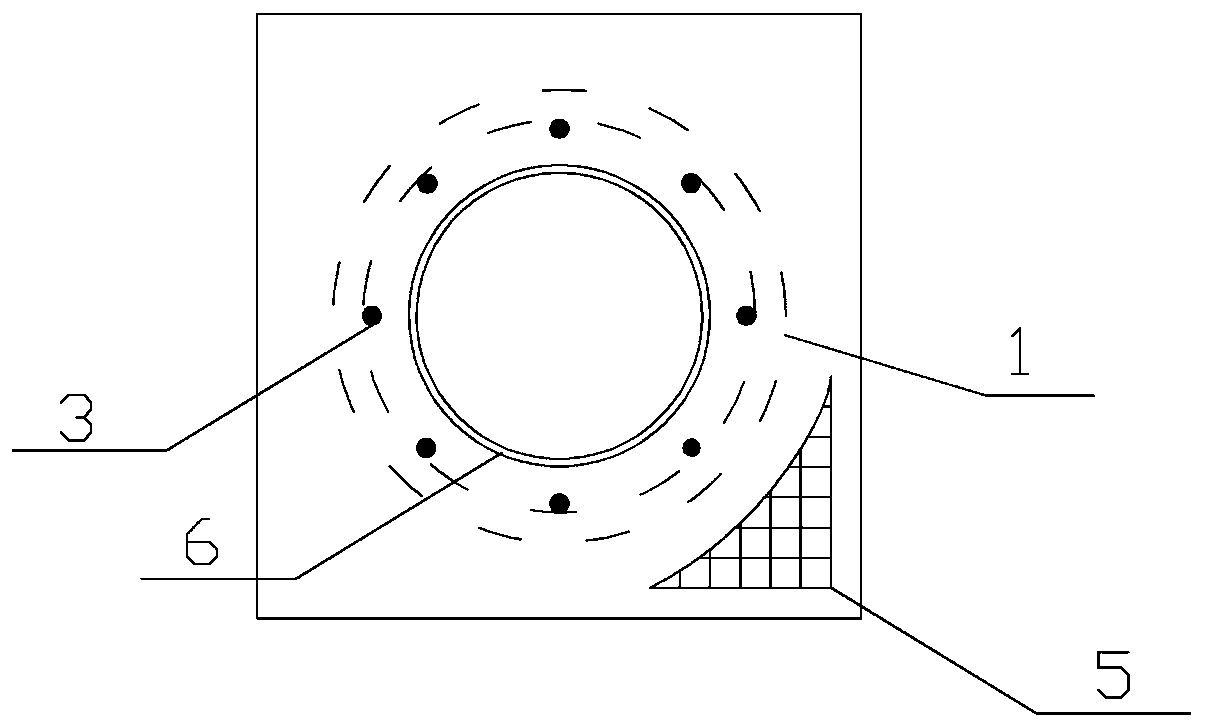

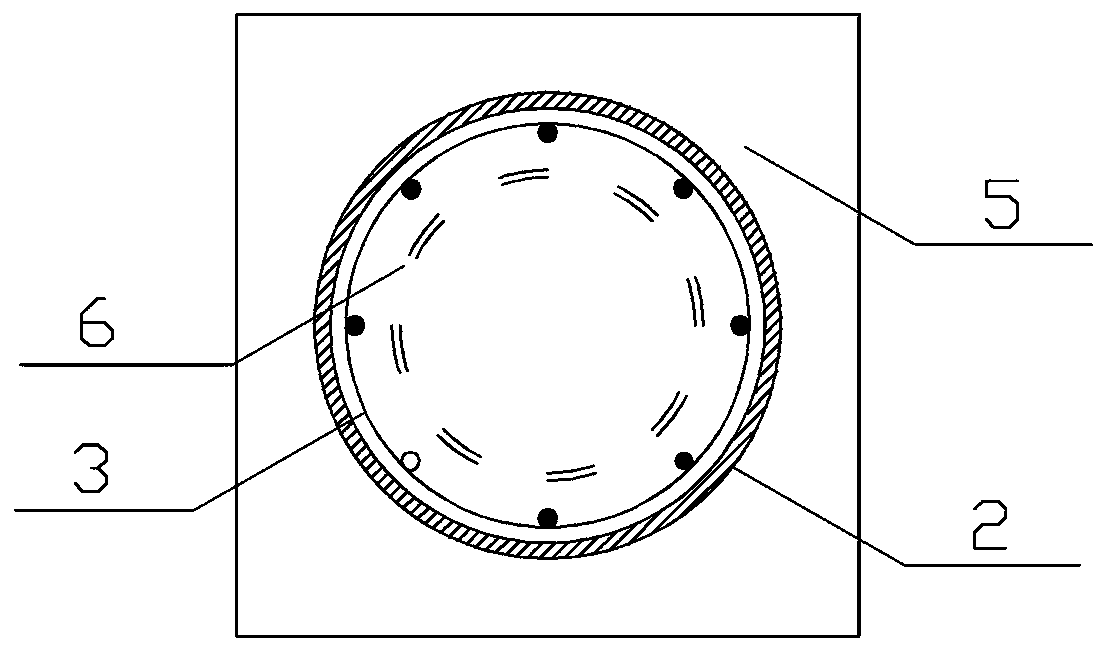

[0058] Such as figure 1 , figure 2 and image 3 As shown, the front view, top view and bottom view of the steel pipe-concrete pile foundation as a temporary foundation of the present invention are respectively provided, which are composed of hole piles 1, steel pipes 2, caps 5 and steel pipe column temporary piers 6, as shown The hole pile 1 is composed of a steel cage 3 and concrete 4, the steel pipe 2 is located under the hole pile 1, the steel pipe 2 and the hole pile 1 are in a vertical state, and the steel pipe 2 and the hole pile 1 are coaxially arranged. The hole pile 1 is formed in the pile hole 1 dug by the workers in layers, the upper end of the steel pipe 2 extends into the bottom of the pile hole, and the lower part of the reinforcement cage 3 is welded together with the overlapping part of the upper end of the steel pipe 2 to realize the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com