Steel frame mechanized assembly-type supporting balcony

A steel frame, assembled technology, used in balconies, building components, buildings, etc., to reduce maintenance difficulty, reduce construction waste, and reduce construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

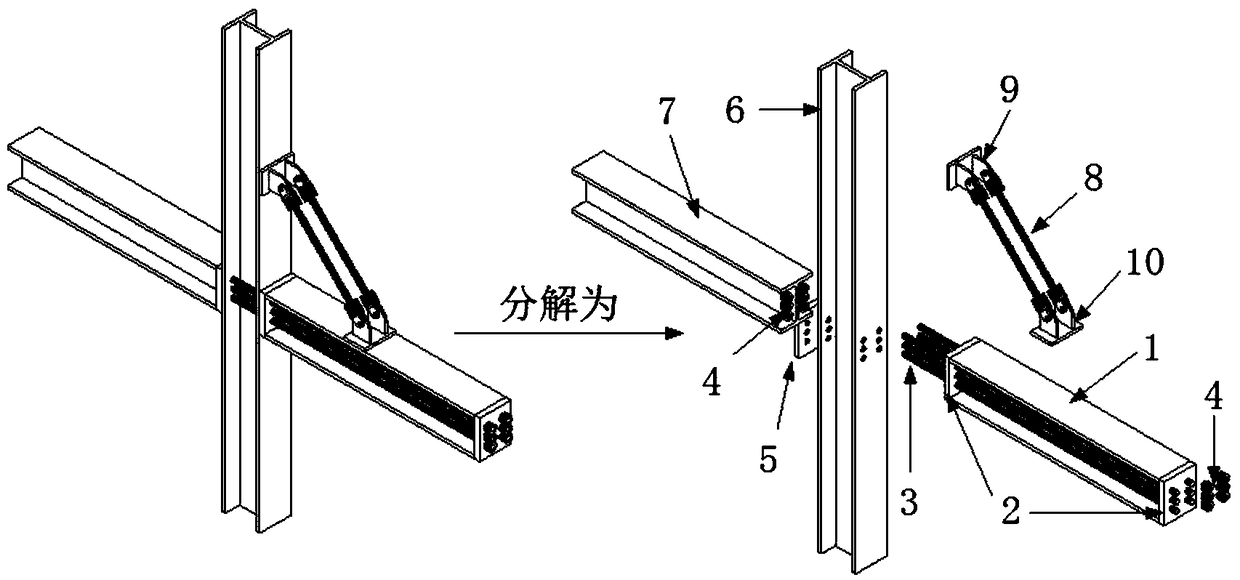

[0029] The present invention is described in detail below in conjunction with accompanying drawing:

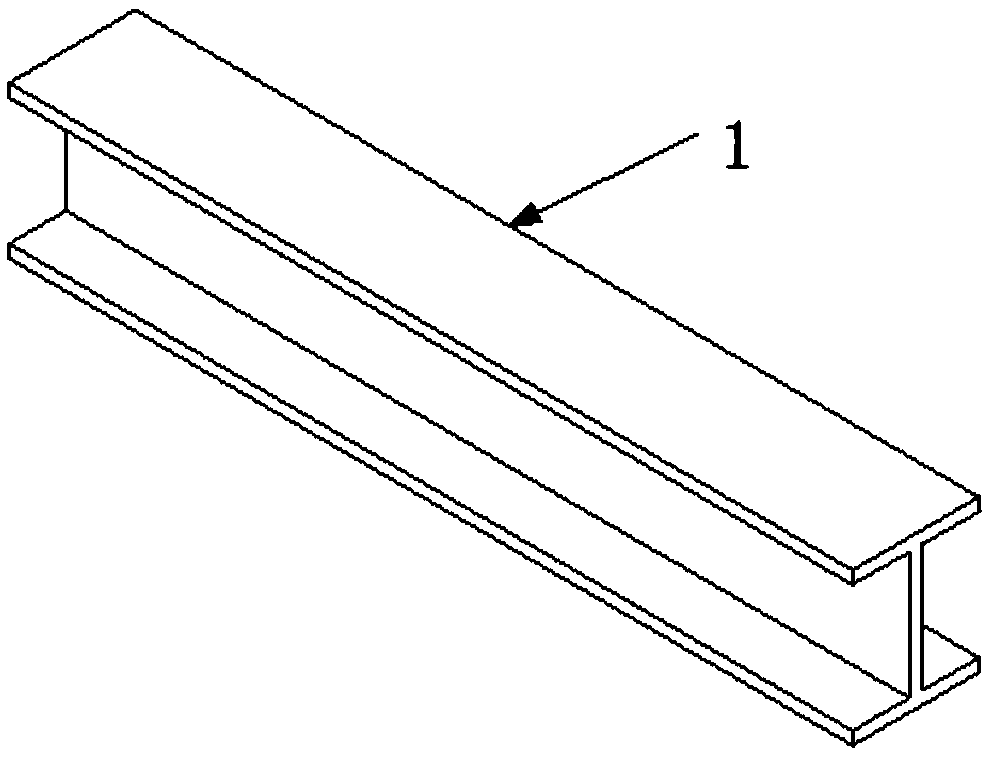

[0030] as attached figure 1 As shown, in a steel frame mechanized assembly type supporting balcony according to the present invention, the section steel 1 used for the cantilever beam is I-beam shown in the figure, and other forms can also be selected according to the actual stress situation. steel;

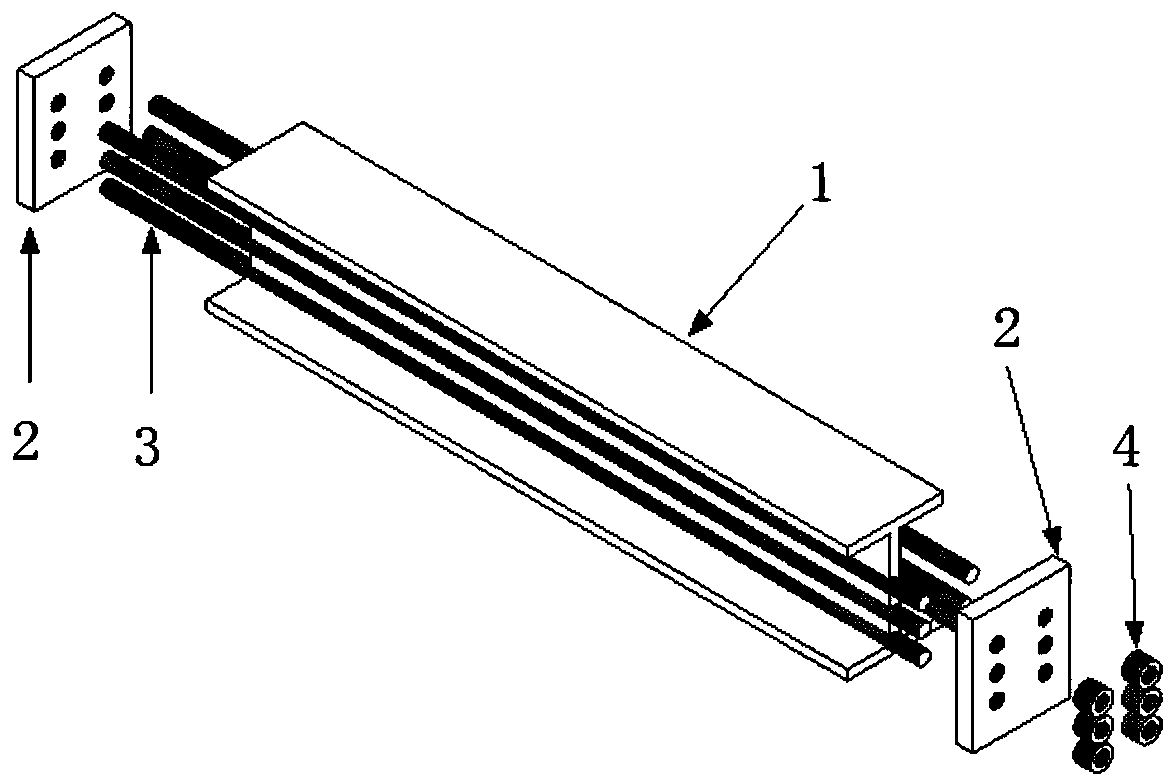

[0031] as attached figure 2 As shown, in a kind of steel frame mechanized assembly type plus support balcony described in the present invention, the composition of described assembly type plus support balcony cantilever beam: the cantilever beam is mainly composed of shaped steel cantilever beam 1, beam end sealing plate 2, It is composed of prestressed cables 3 and permanent anchorages 4, wherein when the beam end sealing plate 2 is prefabricated in the factory, holes of different sizes are reserved according to the selected prestressed cables 3, so as to facilitate the penet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com