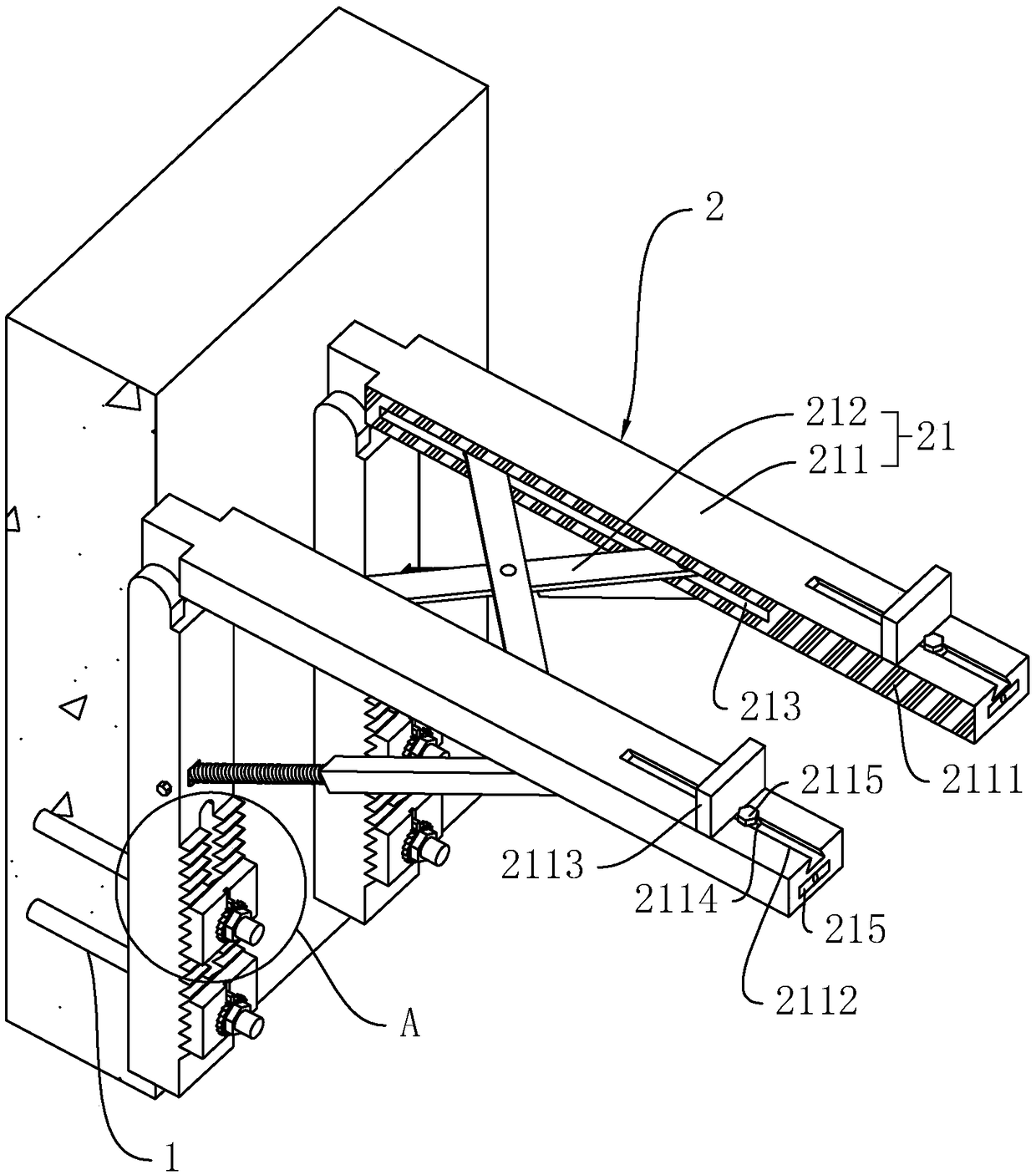

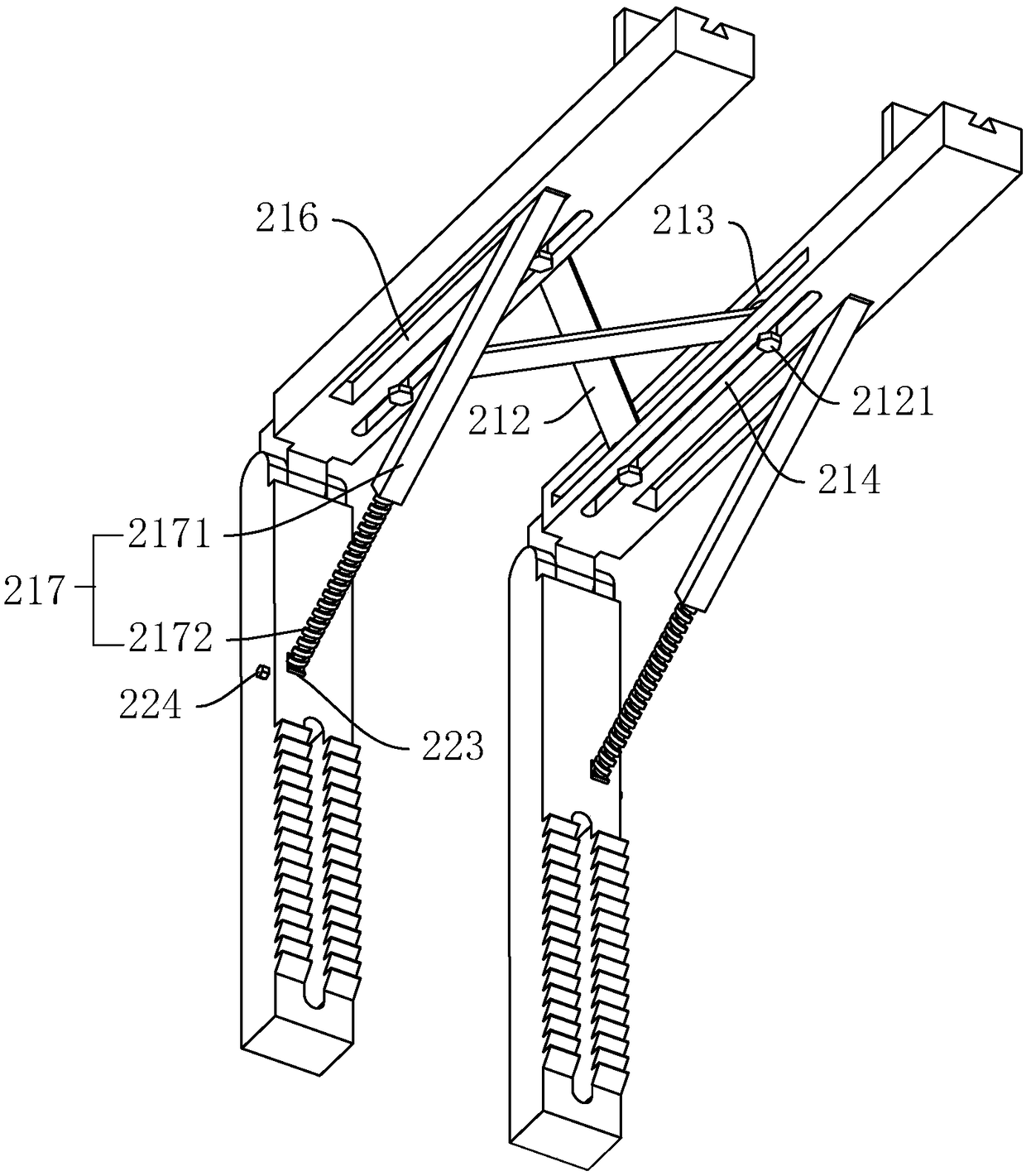

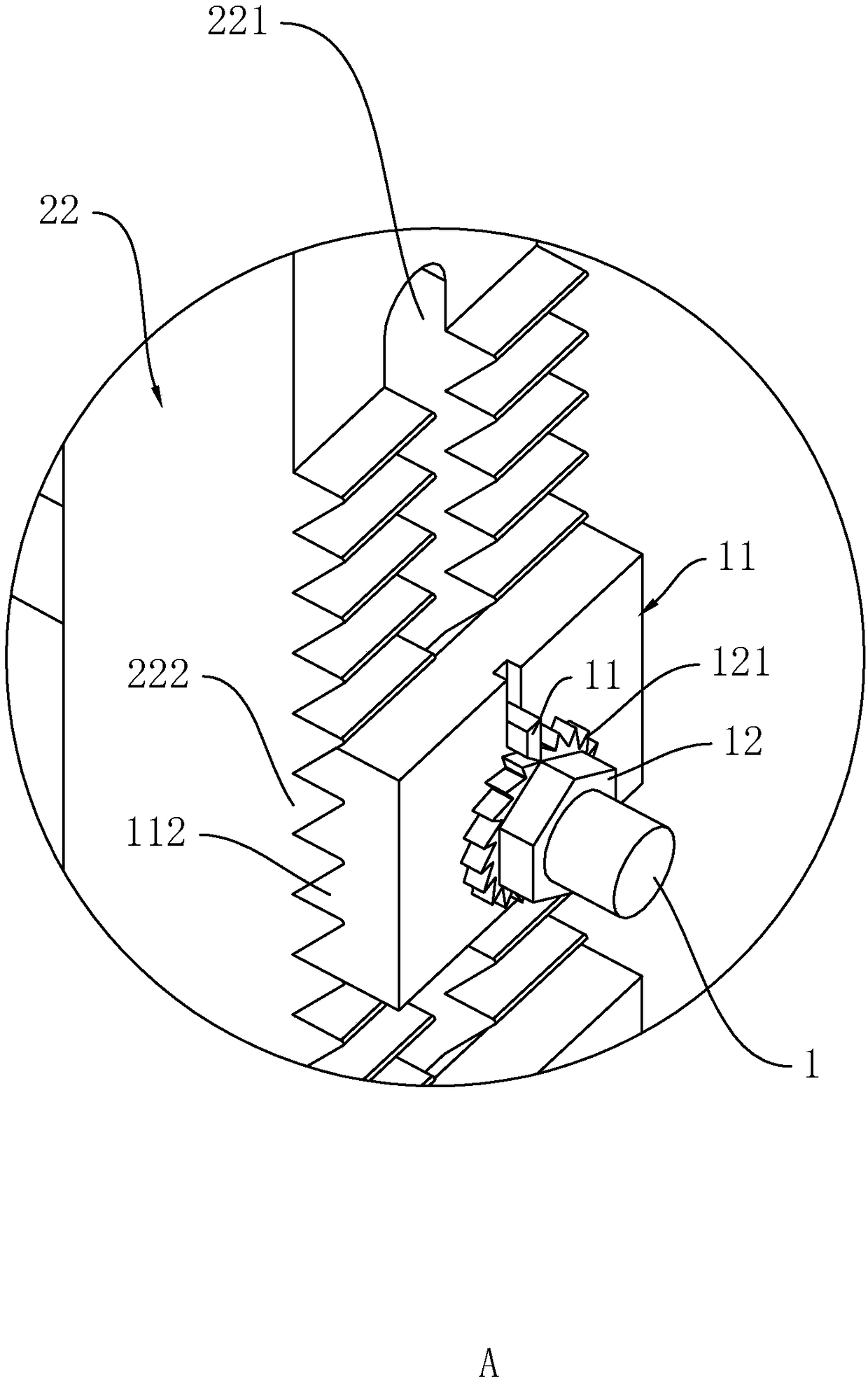

Support structure and construction method of cantilever plate for house building project

A supporting structure and cantilevered slab technology, which is applied to building structures, on-site preparation of building components, pillars, etc., can solve problems such as bolt loosening, steel frame support structure wall movement, and influence on cantilever slab pouring, etc. Achieve the effects of preventing detachment, facilitating pouring, and reducing occupied space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0058] Embodiment 2: A construction method of a cantilevered slab for house construction, comprising the following steps:

[0059] Step 1, planting the wall screw 1, including the following steps:

[0060] 1. Positioning: Mark the drilling marks according to the design requirements. If there are stressed steel bars on the wall, the drilling positions can be adjusted appropriately, but they should be planted inside the stirrups or inside the step-by-step bars;

[0061] 2. Drilling: Use an electric hammer or air drill to form a hole. If the steel bar is encountered, adjust the hole position to avoid it. If a drilling machine is used to form a hole, the debris in the drilled hole should be rinsed with crystal water and dried in the sun;

[0062]3. Hole cleaning: After drilling, check the depth and diameter of the hole. After passing the test, blow out the dust in the hole with compressed air, then use a brush to clean the hole wall, and then blow it out with compressed air again....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com