Sealing technique for restraining leakage flow loss of back cavity of centripetal turbine

A leakage flow and back technology, applied in the direction of leakage prevention, engine components, machines/engines, etc., can solve unconsidered problems, achieve the effect of improving utilization efficiency, strong adaptability, and easy maintenance and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

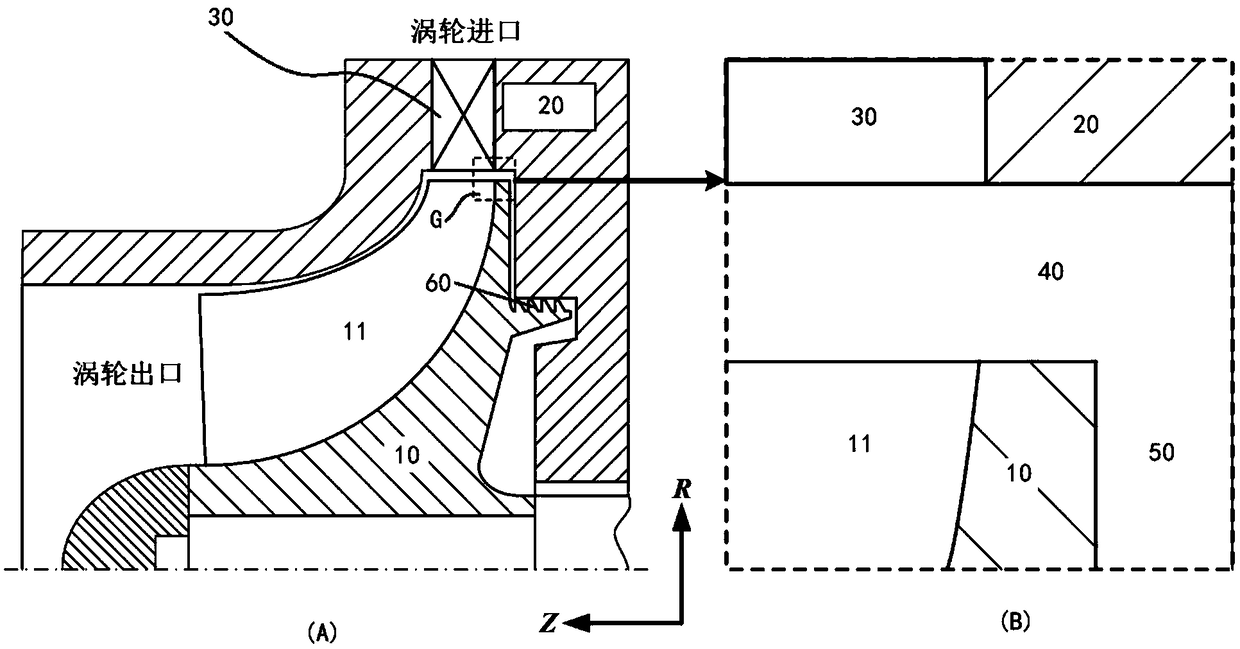

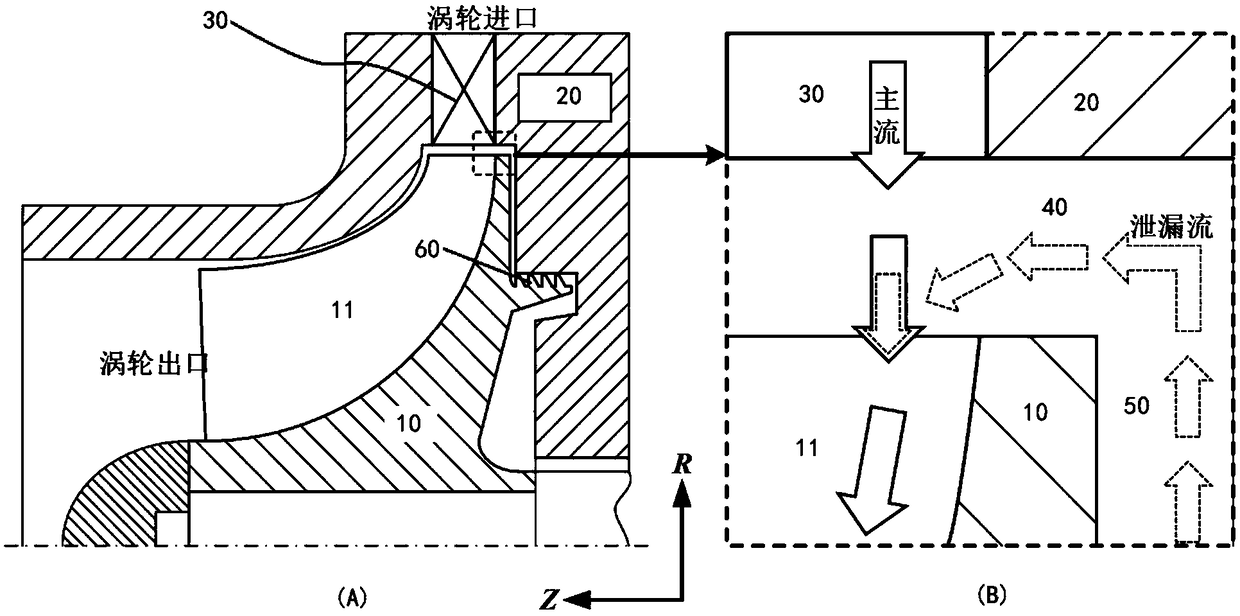

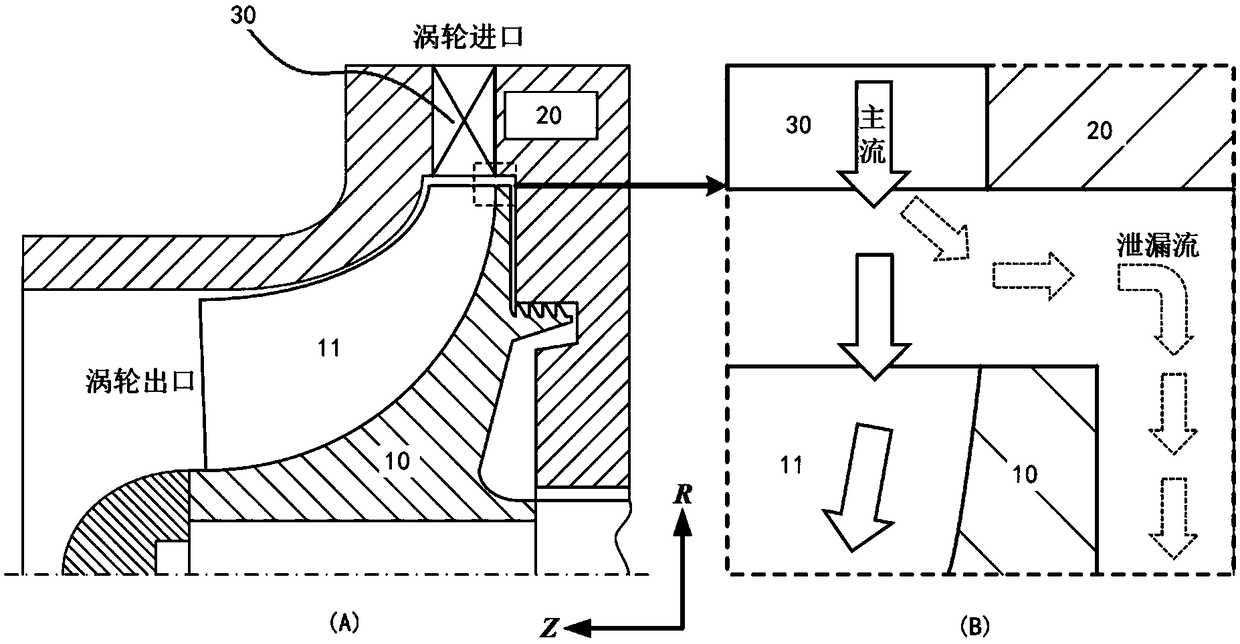

[0026] Such as Figure 4 As shown, the structure for suppressing the leakage flow loss of the back cavity of the centripetal turbine impeller of the present invention is used to suppress the leakage movement of the fluid from the back cavity of the impeller to the main channel of the impeller. The centripetal turbine includes an impeller 10 and a casing 20. The surface of the impeller 10 is uniformly distributed with a plurality of blades along its circumference. There is a tip gap 40 between the top of the impeller 10 and the casing 20. The impeller back cavity 50 is formed between them, and the wheel top gap 40 communicates with the impeller back cavity 50. The middle radial position of the impeller back is provided with a grate tooth 60 and forms a g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com