Variable heat energy recovery system and method for cogeneration unit

A cogeneration unit and heat energy recovery technology, applied in mechanical equipment, steam engine devices, engine components, etc., can solve the problems of application scenarios and small market volume, and achieve the effect of ensuring normal operation, saving costs, and reducing investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

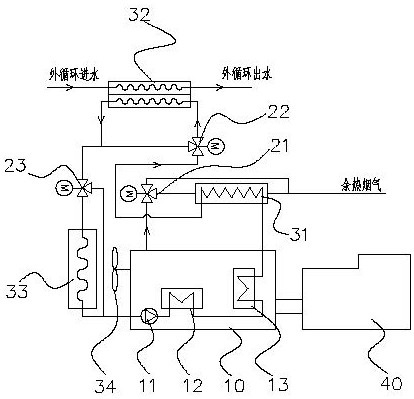

[0021] like figure 1 As shown, the present embodiment provides a variable heat energy recovery system for cogeneration units, including a gas internal combustion engine 10, a water pump 11, a cooler 12 connected to the water pump 11, and a cooling system connected to the gas internal combustion engine 10 are provided. The cylinder liner 13 connected with the device 12, the exhaust port of the gas internal combustion engine 10 is connected with the first channel inlet end of the first heat exchanger 31 through the first valve 21, and the cylinder liner 13 is connected with the first heat exchanger 31 is connected to the second passage inlet end of the first heat exchanger 31, and the second passage outlet end of the first heat exchanger 31 is connected to the first passage inlet end of the second heat exchanger 32 through the second valve 22, and the second valve 22 is connected to the first passage inlet end of the second heat exchanger 32. The third valve 23 is connected, the...

Embodiment 2

[0033] This embodiment provides a method for recovering variable heat energy of a combined heat and power unit. According to the variable heat energy recovery system of a cogeneration unit described in Embodiment 1, the controllable recovery of energy includes the following steps: Step S1: Control the first valve 21, the first heat exchange is performed on the internal circulating fluid of the gas internal combustion engine 10; Step S2: Control the opening of the second valve 22, and perform a second heat exchange on the internal circulating fluid after the first heat exchange or Avoid performing a second heat exchange on the internal circulating fluid after the first heat exchange; Step S3: Control the opening of the third valve 23, and transport the internal circulating fluid after the second heat exchange to the gas internal combustion engine 10, Return to step S1 until the second heat exchange is performed on the internal circulating fluid after the first heat exchange in s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com