Solid waste treatment system

A solid waste and treatment system technology, applied in jet propulsion devices, gas turbine devices, machines/engines, etc., can solve the problems of environmental hazards, long construction period, low power generation efficiency, etc., and achieve compact system structure and improve living environment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

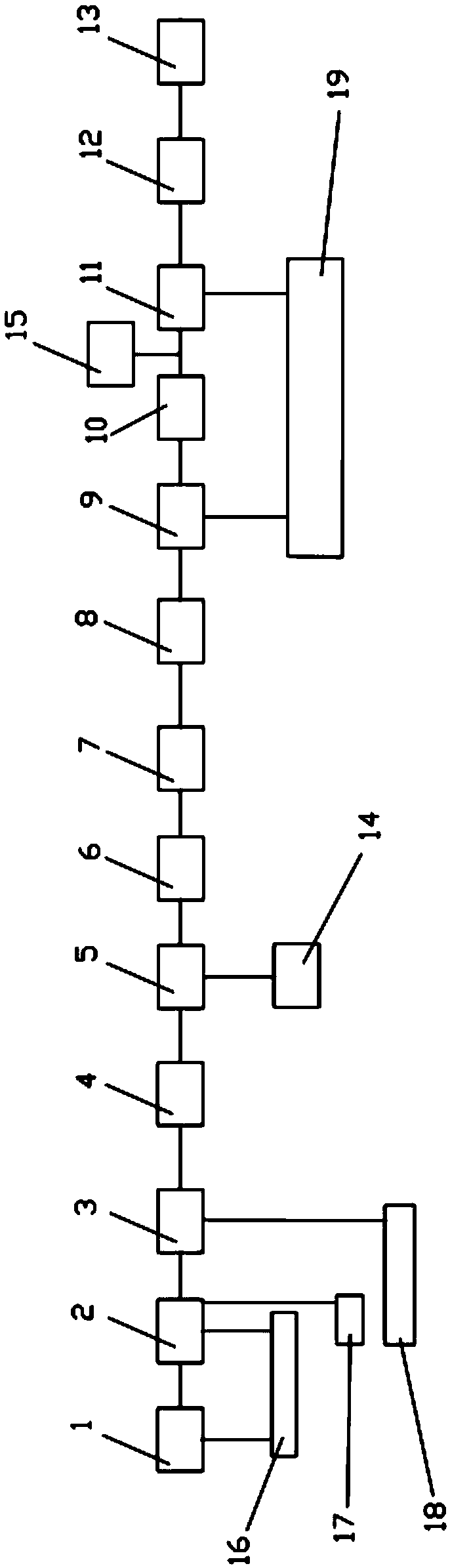

[0012] Embodiment one: figure 1 A solid waste treatment system is shown, which includes: a discharge hall 1, a garbage storage pit 2, a drum screen 3, a crusher 4, an air density separator 5, and a grinder arranged in sequence 6. Rotary dryer 7, fuel particle machine 8, anoxic pyrolysis gasification system 9, clean gas storage tank 10, gas generator 11, transformer 12, power grid 13, and the air flow density separator 5 is also connected with An eddy current separator 14, a safety torch 15 is provided between the clean gas storage tank 10 and the gas generator 11, and the garbage storage pit 2 evaporates the moisture in the garbage to between 20% and 30%. The drum sieve 3 separates large-size garbage and small-size garbage, the airflow density separator separates the organic substances with large quality and small quality, and the eddy current separator 14 screens the organic substances with large quality again , the iron, stone, glass and non-ferrous metals after screening h...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap