Backflow type detonation tube structure for pulse detonation engine

A technology of pulse detonation and detonation tube, which is applied in the direction of machines/engines, rocket engine devices, mechanical equipment, etc., can solve the problems of increasing weight, keeping the central axis unchanged, and affecting the working frequency, etc., so as to shorten the axial length, The effect of reducing the axial distance and reducing the mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described now in conjunction with accompanying drawing:

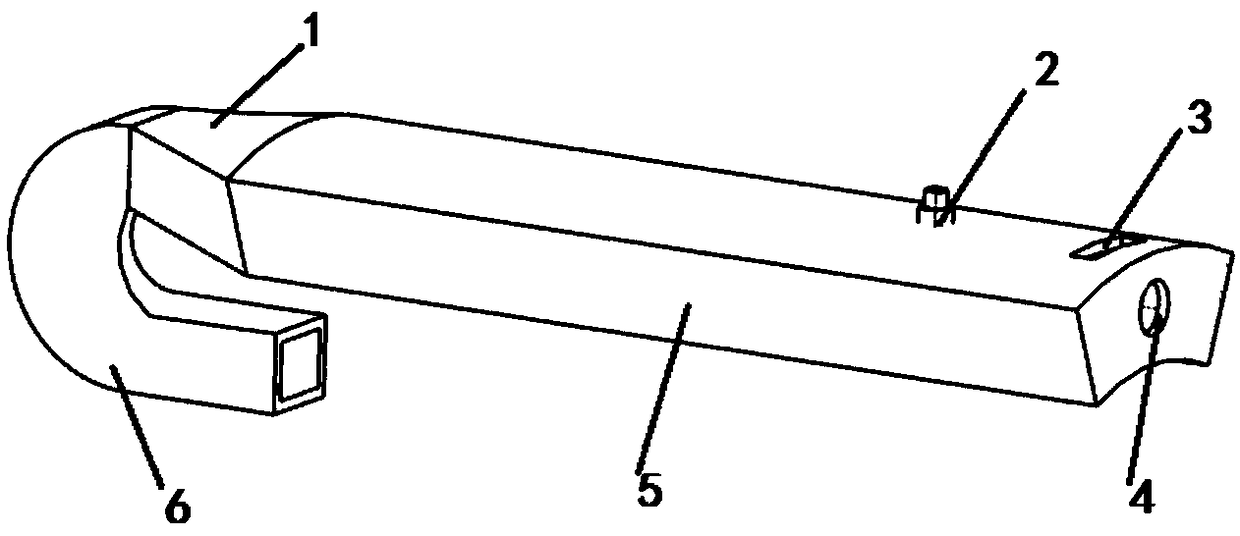

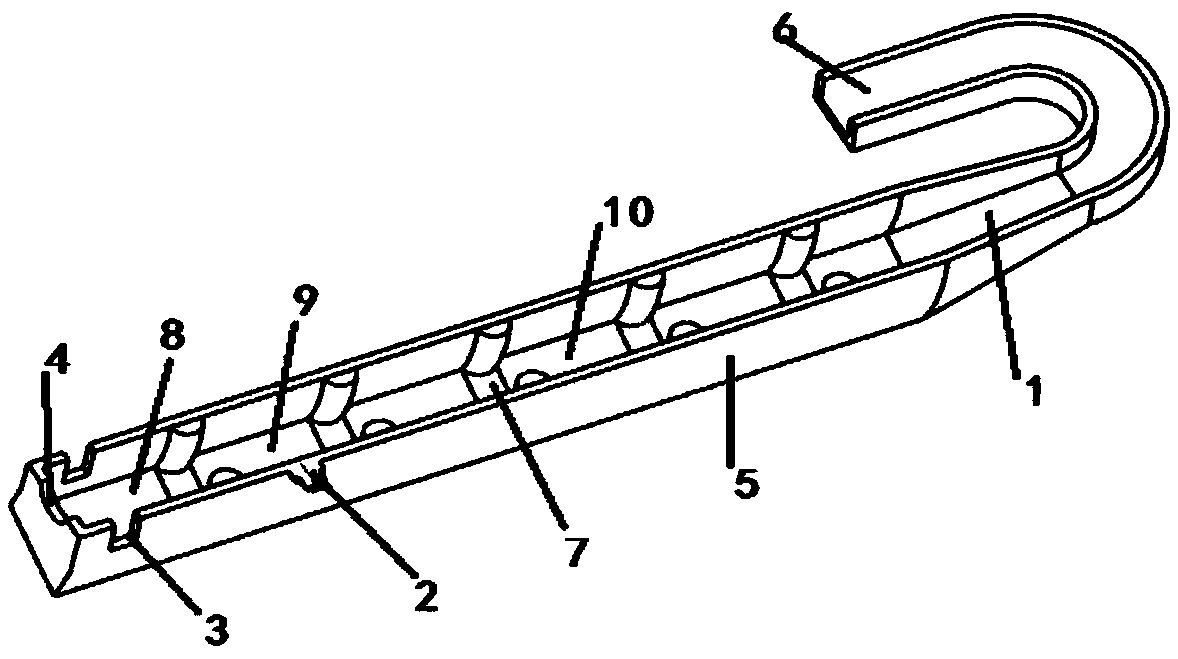

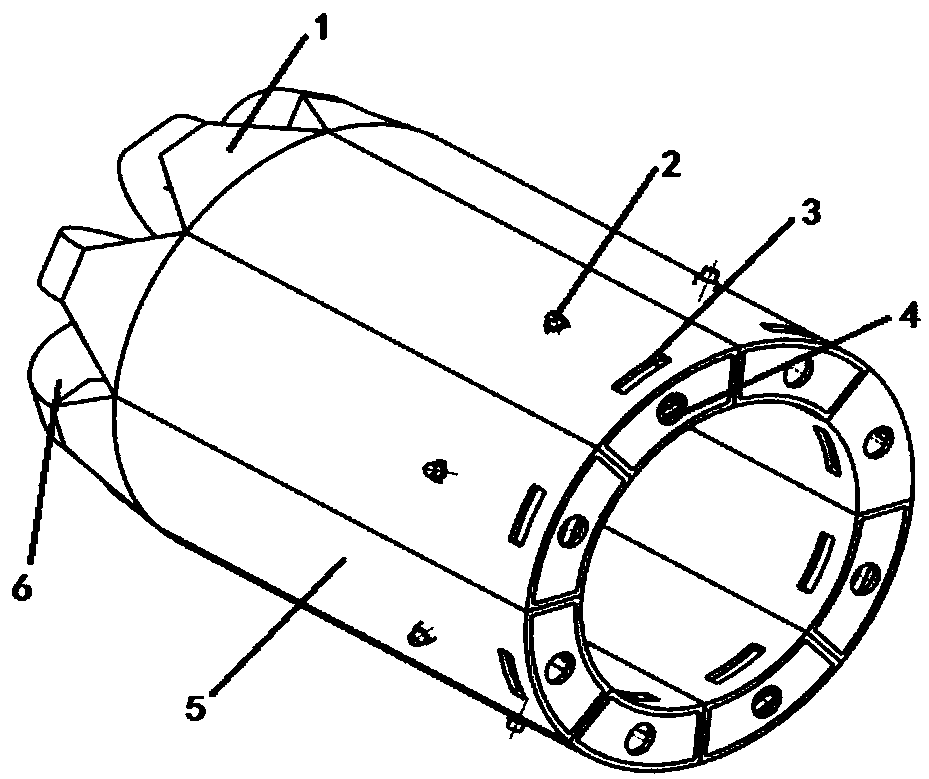

[0018] to combine figure 1 and figure 2 , the present invention proposes a backflow pulse detonation engine detonation tube structure, which can effectively shorten the radial distance of the detonation tube, reduce the mass of the detonation engine, and enable the engine to obtain greater power. figure 1 It is a schematic diagram of the structure of the backflow detonation tube. The backflow detonation tube includes the detonation tube (1, 5, 6), the spark plug (2), the auxiliary air inlet (3), the main air inlet (4), and fan-shaped obstacles (7). The detonation tube is a curved tube structure, which is divided into a fan-shaped straight section (5), a transition section (1) and a rectangular curved section (6). The main air inlet (4) and the auxiliary air inlet (3), the main air inlet (4) is located at the axial inlet, and the fuel injection pipe will extend from the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com