Online monitoring system and method of exhaust steam enthalpy value of low pressure cylinder of steam turbine

A monitoring system and low-pressure cylinder technology, applied in the direction of measuring devices, measuring heat, instruments, etc., can solve the problems that it is difficult to meet online monitoring, many parameters are required, and the measurement technology is not mature enough.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

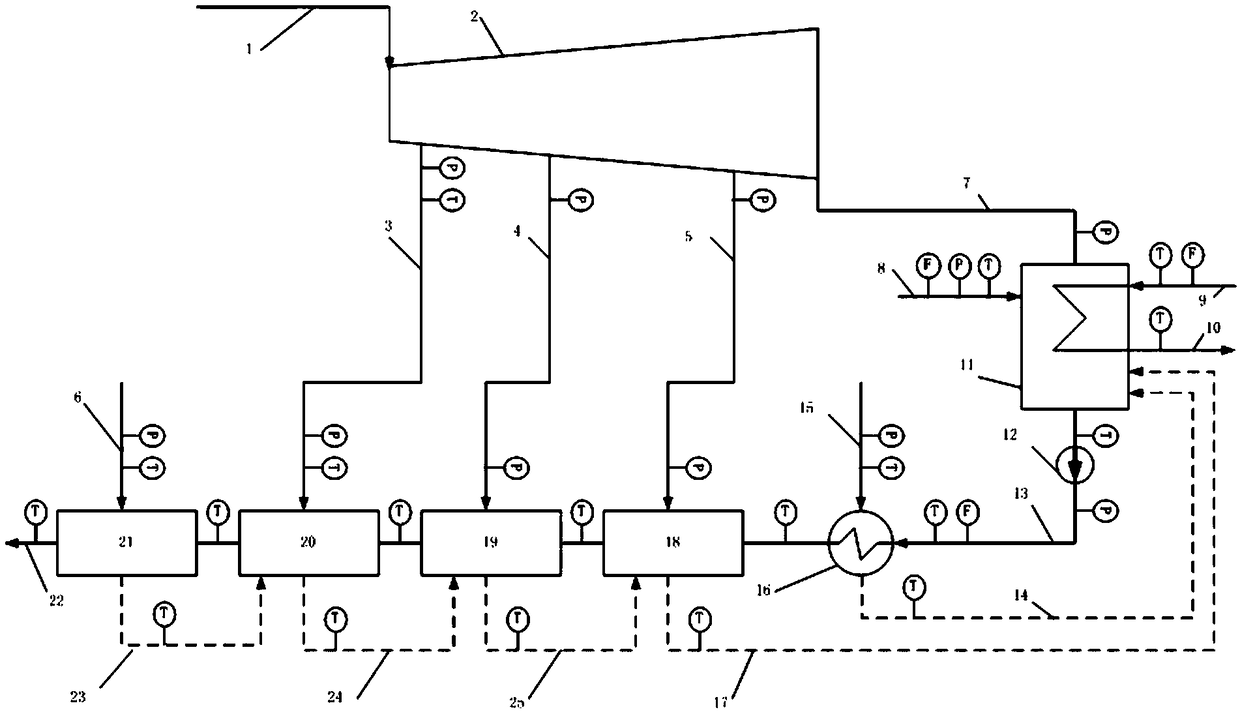

[0060] like figure 1As shown, the steam turbine low-pressure cylinder exhaust enthalpy online monitoring system of this embodiment includes a low-pressure cylinder 2, a condenser 11, a condensate pump 12, a shaft plus 16, and four sets of low-pressure heaters. The four sets of low-pressure heaters are respectively LP 1 (18), LP 2 (19), LP 3 (20), LP 4 (21); low-pressure cylinder 2 outlet and condenser 11 steam inlet are connected through low-pressure cylinder exhaust pipe 7, condensate pump 12. Shaft plus 16, low plus 1 (18), low plus 2 (19), low plus 3 (20) and low plus 4 (21) are sequentially arranged at the condensate outlet and condensate outlet of condenser 11 along the water flow direction Between pipelines 22; low plus 1 (18), low plus 2 (19) and low plus 3 (20) pass through corresponding steam pipes respectively, namely low plus 1 st...

Embodiment 2

[0067] On the basis of the first embodiment, the online monitoring system for the exhaust steam enthalpy of the low-pressure cylinder of the steam turbine in this embodiment adds a terminal display module; the terminal display module is connected with the data processing module to receive and display the data processed by the data processing module .

Embodiment 3

[0069] In this embodiment, for the on-line monitoring system for the exhaust enthalpy value of the steam turbine low-pressure cylinder of the second embodiment, its monitoring method is as follows: figure 2 shown, including the following steps:

[0070] 1) Real-time data collection;

[0071] 1.1) Raw data collection:

[0072] The sensors of the online monitoring system for exhaust enthalpy of low-pressure cylinders of steam turbines collect various data and transmit them to the data processing module. The data to be collected are as follows:

[0073] Table 1 Raw data collection table

[0074] name

unit

the symbol

name

unit

the symbol

Low plus 4 inlet steam pressure

MPa

P 4,q

Shaft plus inlet steam temperature

℃

t zq

Low plus 4 inlet steam temperature

℃

t 4,q

Condensate flow

t / h

D c

Low plus 3 extraction pressure

MPa

P c 3,q

Low Plus 4 Hydrophobic Temperature

℃

t 4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com