Non-destructive measurement method of reinforcement content in particle-reinforced metal matrix composite

A technology of composite materials and particle reinforcement, which is applied in the direction of measuring devices, analyzing materials, and using sound waves/ultrasonic waves/infrasonic waves for material analysis, etc. The lift-off effect has a large influence, and achieves the effect of fast measurement speed, reduced time and economic cost, and low requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

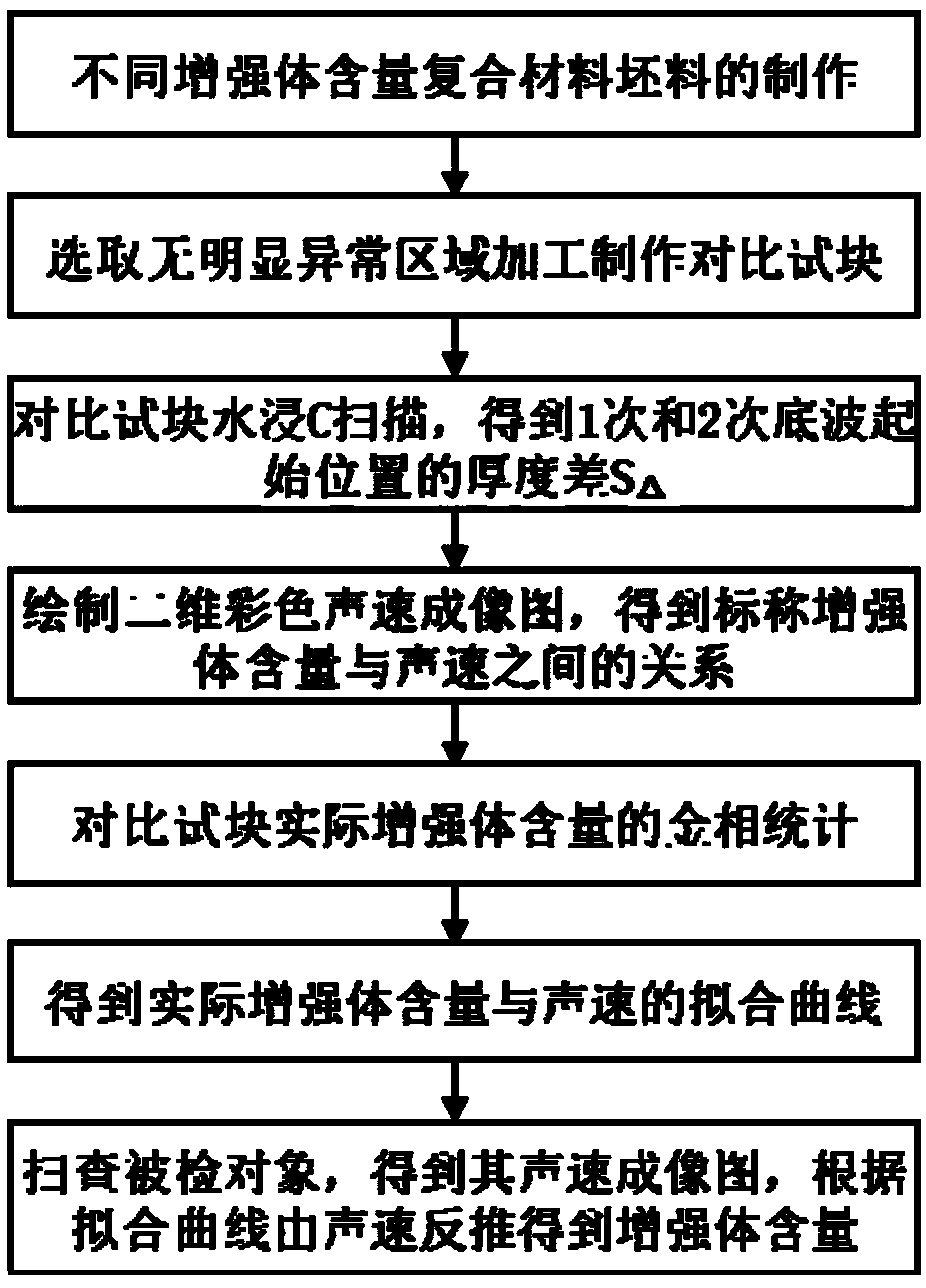

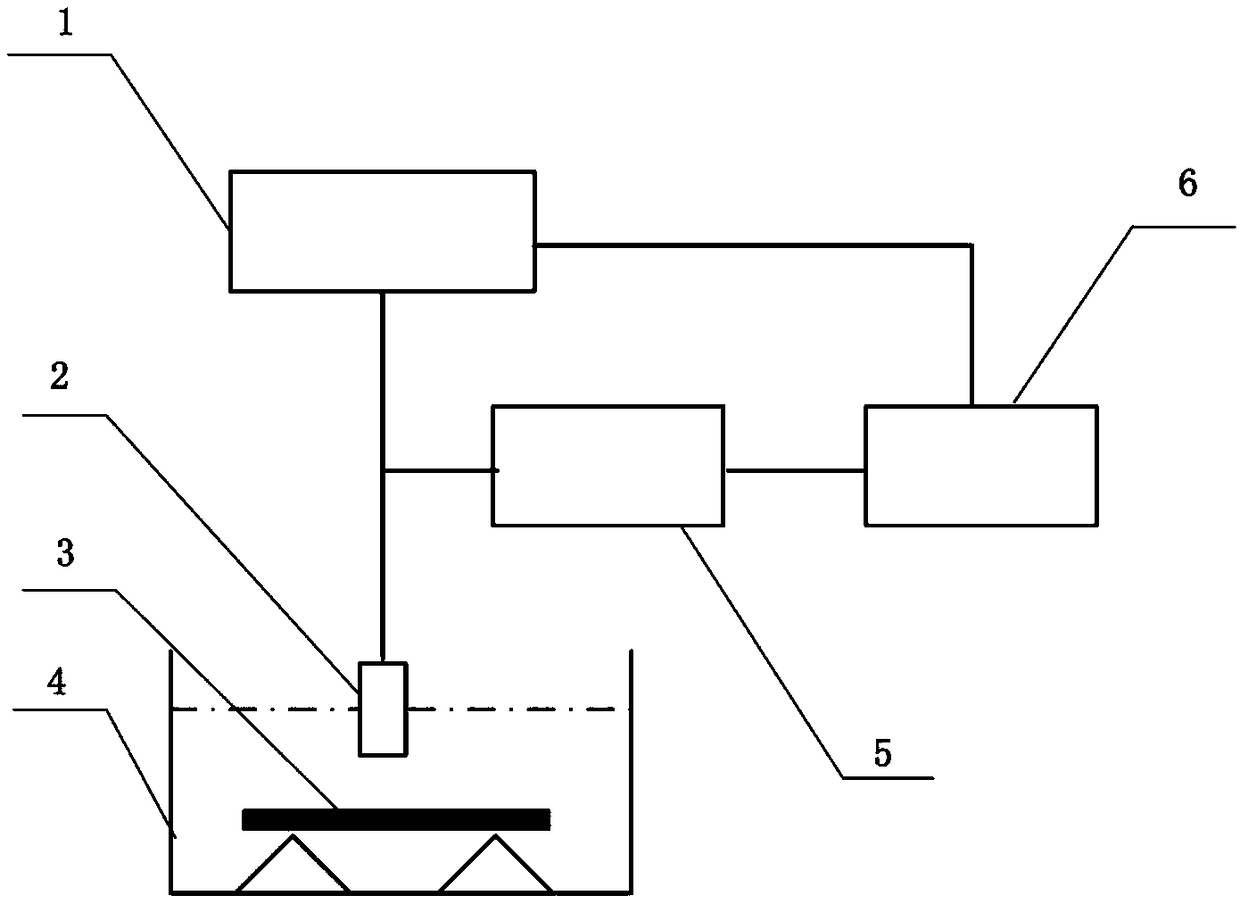

Method used

Image

Examples

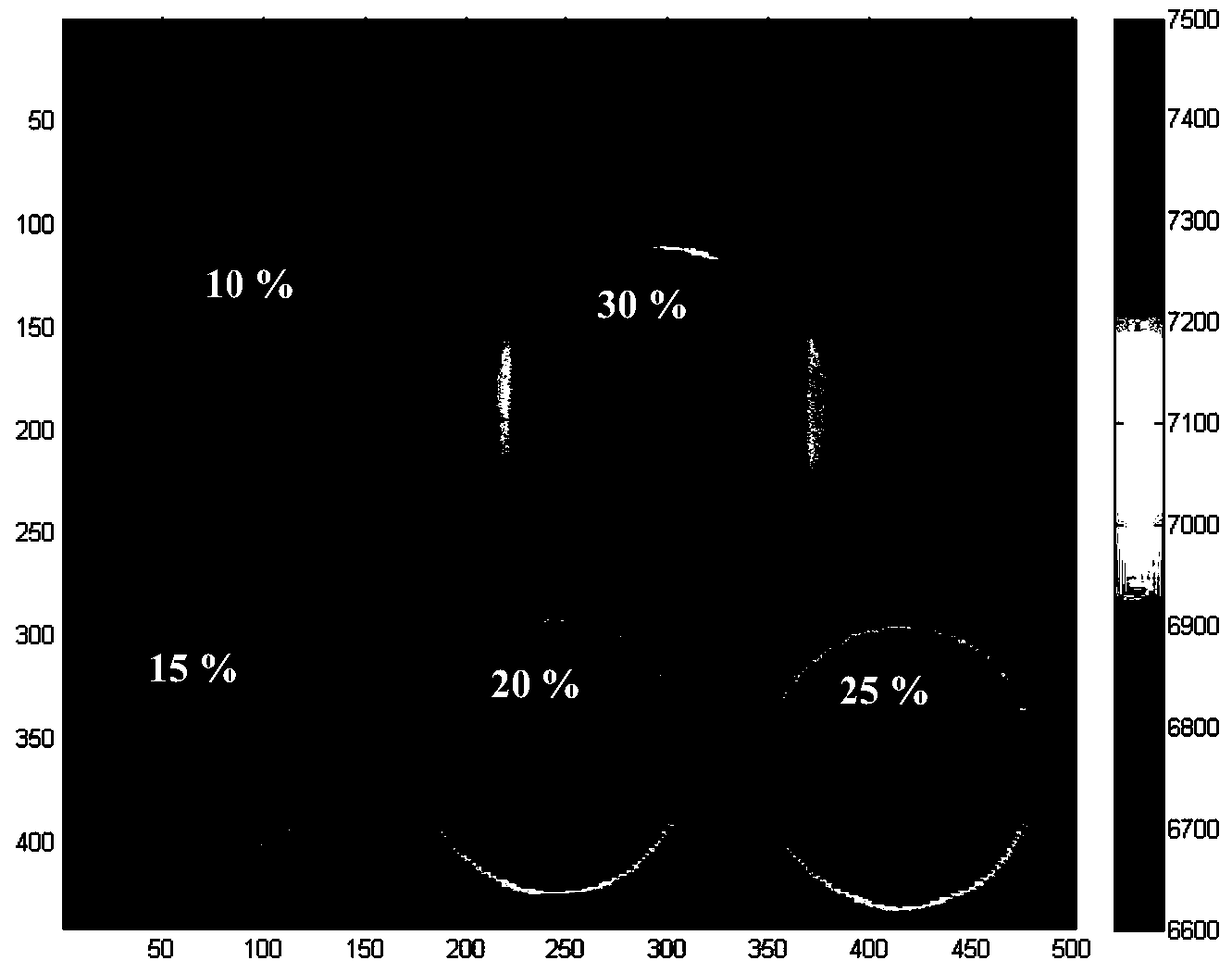

Embodiment 1

[0064] The substrate grade is 6092 SiC particle reinforced aluminum matrix (SiC p / Al) composite material, the particle size of the aluminum powder is 28 μm, the particle size of the SiC particle is 5 μm, the overall size of the composite material is 100×80×60 mm, and the measurement steps of the reinforcement SiC particle content are as follows:

[0065] (1) Preparation of comparison test block

[0066] (1.1) Production of composite blanks with different reinforcement contents

[0067] Using powder metallurgy technology, select aluminum powder with brand name 6092, particle size of 28 μm, and SiC particles with particle size of 5 μm, after accurate weighing, atomize powder, powder mixing, ball milling, drying, sieving, packaging Set, degassing, hot isostatic pressing and other processes to produce a set of SiC with SiC particle volume fractions of 10%, 15%, 20%, 25%, and 30%. p / Al composite blanks, the size of each blank is Φ80×80mm. Ensure that the manufacturing process ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com