Method for detecting total voltage and insulation resistance of high voltage battery system

A technology of insulation resistance and battery packs, which is applied in the directions of high resistance measurement, current/voltage measurement, resistance/reactance/impedance measurement, etc. It can solve the problems of insulation resistance error, high-voltage detection interference, and susceptibility to interference, etc., to achieve good Accuracy, strong anti-interference ability, and the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

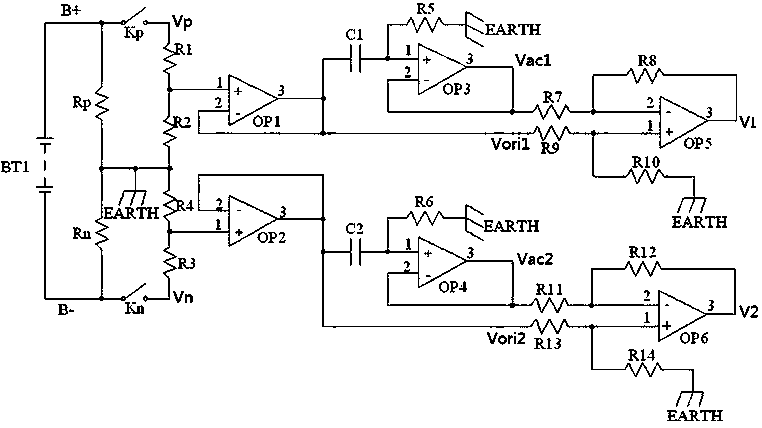

[0036] As an independent module in the electric vehicle BMS (battery management system), the invention communicates with the BMS main control module through the CAN bus, detects the insulation performance of the system in real time, and reports to the main control through the CAN bus, once the insulation is damaged , the main control takes corresponding measures in time, and related actions include: cut off the contactor, sound and light alarm, etc.

[0037]The insulation detection module includes the following parts: battery pack positive and negative buses (B+, B-), high voltage switch (Kp, Kn), resistor network (R1, R2, R3, R4), signal processing circuit (OP1, OP2, OP3 , OP4, OP5, OP6), Dadi (car body). Rp and Rn are the insulation resistance between the positive and negative bus bars and the earth (car body) respectively. It is controlled by an external microcontroller and sampled by AD, and sent to the main control unit through the field bus.

[0038] In this embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com