Catalyst, preparation method thereof, cathode and electrochemical system

A catalyst and electrochemical technology, applied in the fields of materials, energy, and the environment, can solve the problems to be improved, and achieve the effect of avoiding clogging of catalytic sites, good electricity production performance, and avoiding the decrease of electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0130] Embodiment 1 prepares pure carbon fiber (Carbon fiber)

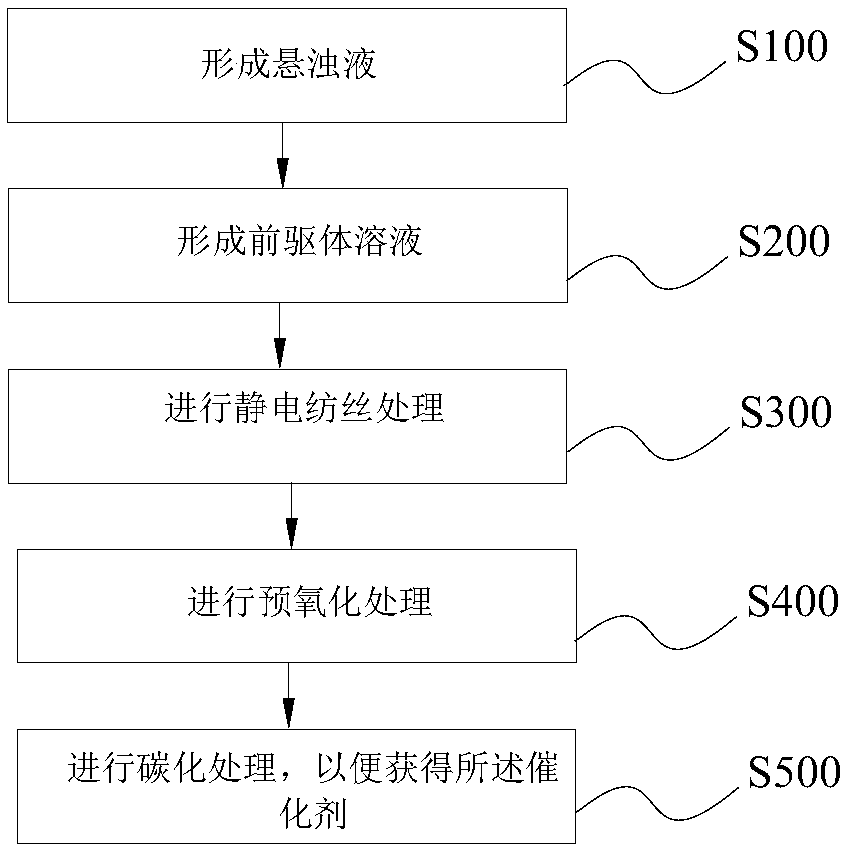

[0131] According to an embodiment of the present invention, the carbon fiber-based material is prepared through an electrospinning-preoxidation-carbonization process, wherein the precursor of the electrospinning is polyacrylonitrile (PAN). The production process of pure carbon fiber catalyst is as follows: take 1g of polyacrylonitrile and dissolve it in 10mL of dimethylformamide (DMF), stir it for about 24 hours to completely dissolve it, and then use this solution to perform electrospinning to obtain fibers. The voltage and negative voltage were 10kV each, a metal plate was used as the receiver, the distance between the needle and the receiver was 15cm, and the flow rate of the syringe was adjusted to 10μL / min. After spinning, the spun fibers were placed in air atmosphere and heated at 280°C for one hour at a heating rate of 1°C / min. After natural cooling, the color turned dark brown, indicating that the pre-oxid...

Embodiment 2

[0132] Embodiment 2 prepares carbon-iron composite fiber (C-Fe fiber)

[0133] Other preparation methods are the same as in Example 1, the difference is that 1g Fe(acac) is added in 10mL spinning precursor solution 3 , that is, iron can be incorporated into the final fiber material.

Embodiment 3

[0134] Embodiment 3 prepares the carbon fiber (Z-C fiber) of ZIF-8 modification

[0135] Other preparation methods were the same as in Example 1, except that 0.59 g of zinc nitrate hexahydrate was dissolved in 4 mL of deionized water; 11.35 g of 2-methylimidazole was dissolved in 40 mL of deionized water; the two were mixed and stirred for 5 minutes to synthesize ZIF-8. After the synthesis, wash with DMF and centrifuge for 2 to 3 times. After washing, take 0.2g of the obtained white powder and ultrasonically disperse it in DMF. After it forms a uniform suspension, weigh 1g of PAN and dissolve it in the solution for spinning. silk can be.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| internal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com