Tea fixation and green leaf cooling all-in-one machine

An all-in-one machine and finishing technology, which is applied in tea processing before extraction, etc., can solve the problems of increasing labor procedures, economic losses, time-consuming and laborious, etc., and achieve the effects of reducing labor procedures, uniform temperature and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

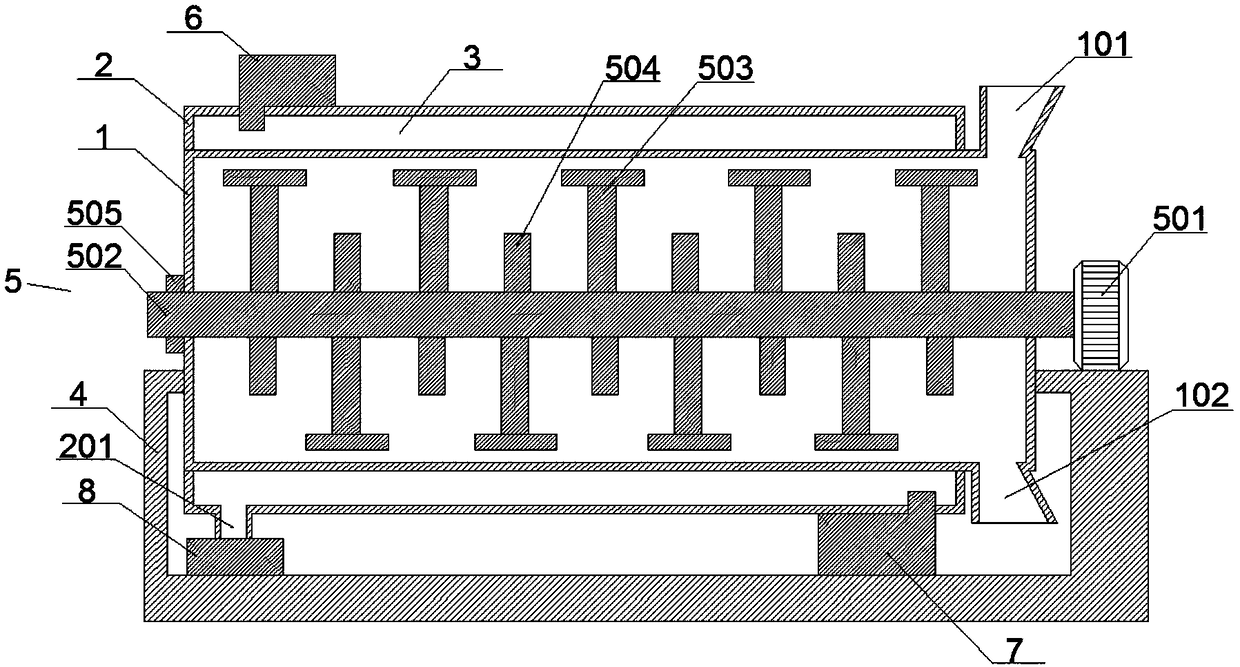

[0022] The structure of this embodiment, such as figure 1 As shown, a kind of integrated machine for fixing and airing tea leaves includes an inner cylinder 1 and a base bracket 4 for supporting, the outer wall of the inner cylinder 1 is covered with an outer sleeve 2, and the outer sleeve 2 and the inner cylinder 1, a cavity 3 is formed, and an air inlet 201 is opened on the wall of the outer sleeve 2, and the air inlet 201 is connected with the air outlet of the steam engine 8, and the outer walls on both sides of the outer sleeve 2 are respectively fixed with extension Enter the first air cooler 6 and the second air cooler 7 in the cavity 3.

[0023] Turn on the steam engine 8 when finishing, and the steam enters the cavity 3 from the air inlet 201, and uniformly heats the inner cylinder 1. After finishing, turn off the steam engine 8, and turn on the first air cooler 6 and the second air cooler 7 at the same time, and the cold air enters The cavity 3 cools the inner cylin...

Embodiment 2

[0025] In this embodiment, on the basis of Embodiment 1, further, the upper and lower side walls of the inner cylinder 1 are respectively provided with a feed port 101 and a discharge port 102, so as to facilitate the feeding and discharging of tea leaves.

Embodiment 3

[0027] In this embodiment, on the basis of Example 1, further, the inner cylinder 1 is provided with a stirring device 5, which is convenient for stirring the tea leaves, so that the temperature of the tea leaves is more uniform, and the effect of killing greens or drying greens is better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com