Charging silt separation device of plug flow reactor

A sediment separation and reactor technology, applied in biological sludge treatment, settling tanks, etc., can solve the problems of low gas production efficiency, poor separation effect, and reduced effective volume of plug flow reactors, so as to reduce heat loss, The effect of increasing the gas production rate and prolonging the cleaning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

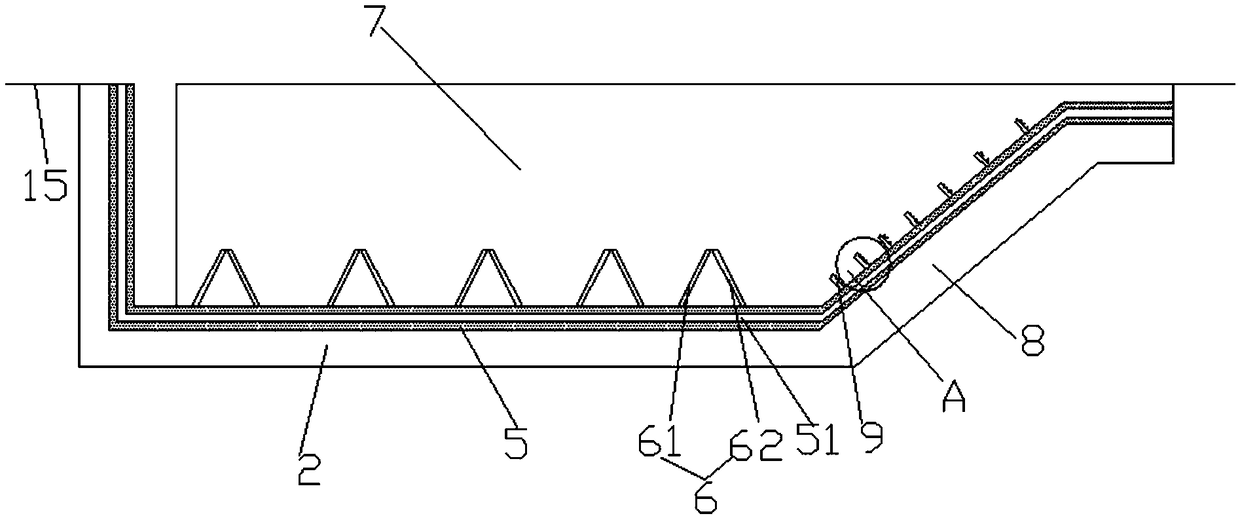

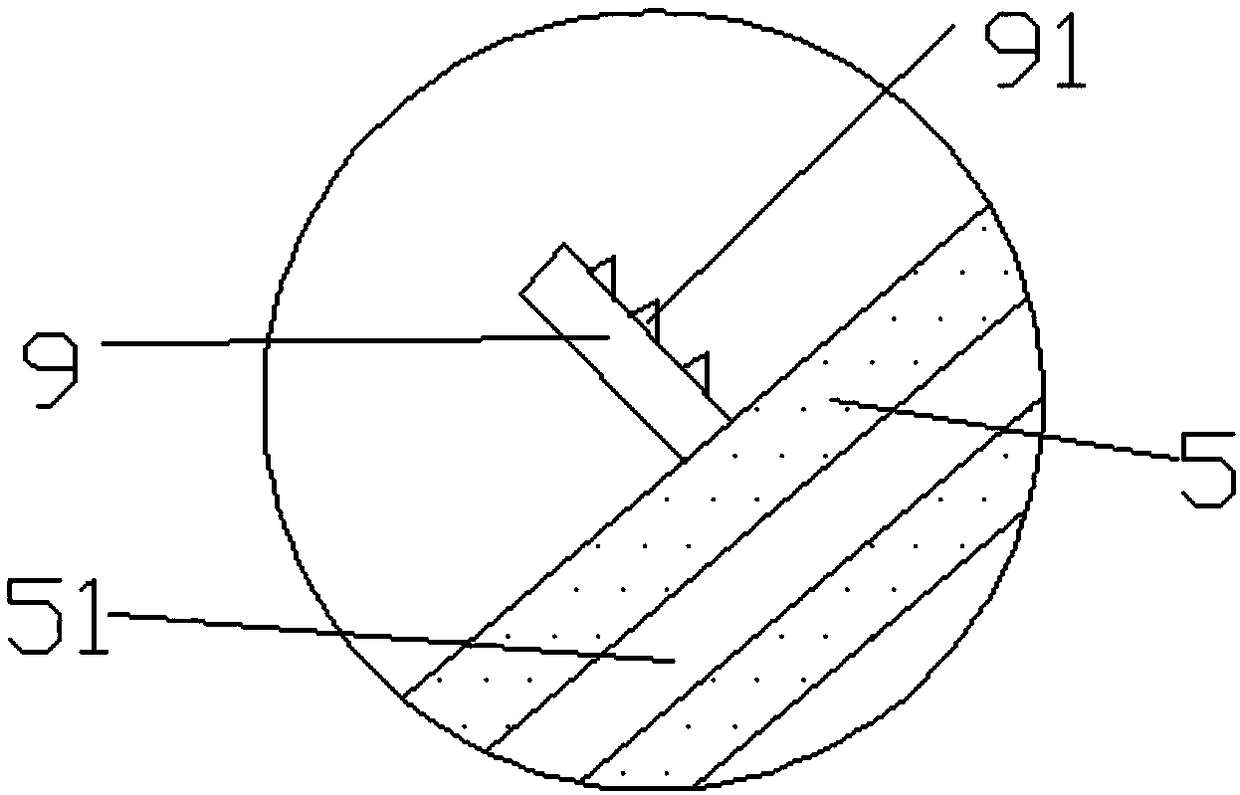

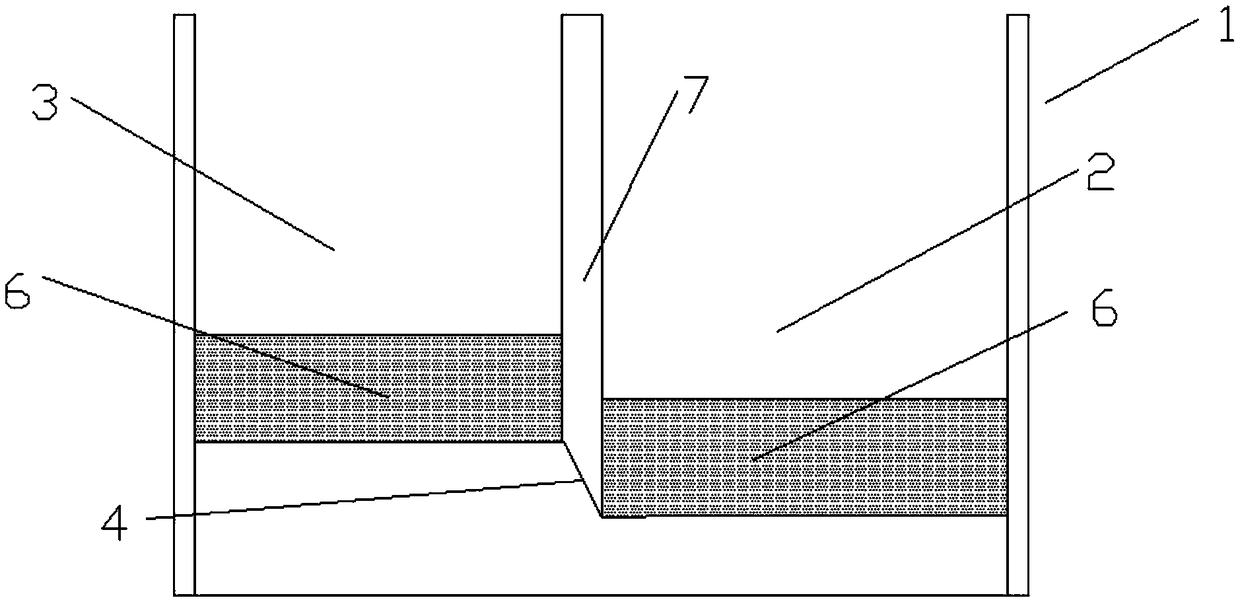

[0023] Such as Figure 1-4 Shown, a kind of plug-flow reactor feeding sediment separation device comprises the settling tank 1 located underground or semi-underground, and the settling tank 1 includes the first settling tank 2 and the second settling tank 3, the first settling tank 2 The feed end of the discharge end and the second settling tank 3 is connected by the transition tank 4, the bottom of the transition tank 4 is inclined, the bottom of the second settling tank 3 is higher than the bottom of the first settling tank 2, and the bottom of the settling tank 1 And the surface of side wall is all provided with thermal insulation layer 5, and thermal insulation layer 5 is provided with vacuum cavity 51, and thermal insulation layer 5 is made of extruded plastic plate, is provided with some baffle plates 6 that can reduce the velocity of sediment flow in the settling tank 1. Wherein, the settlement tank 1 is made of concrete. The invention can realize the sediment separati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com