Miniature film pretreatment test tank for rapid troubleshooting and analysis of problems

A technology for analyzing problems and testing tanks, applied in the field of thin film pretreatment equipment, can solve problems such as inappropriate ratio, excessive parameters, and quality defects in batch electrophoresis, and achieves the effect of simple operation, simple structure and excellent ergonomics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

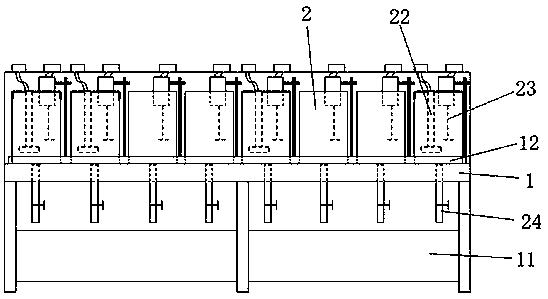

[0020] Please see attached figure 1 , a kind of micro-film pretreatment test tank for rapid investigation and analysis of problems, including a test bench 1, several groups of test tank assemblies and drain tanks 11 installed on the table of the test bench 1; each group of test tank assemblies includes Test tank 21, constant temperature heating device 22, stirring device 23 and drain pipe 24, test tank 21 is installed on the table top of test bench 1, constant temperature heating device 22 is installed in the test tank 21 through bracket, stirring device 23 is passed through motor etc. The control device is arranged in the test tank 21, which is convenient for heating and stirring operations in the pretreatment process; the bottom of the test tank 21 is welded with a drain pipe 24, and the lower part of the test bench 1 is provided with a drain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com