Two-dimensional vibrating table for precision ultrasonic machining

A technology of ultrasonic machining and two-dimensional vibration, which is applied in the direction of metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of large grinding force, low workpiece surface processing accuracy, low material removal rate, etc., to improve the applicable sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

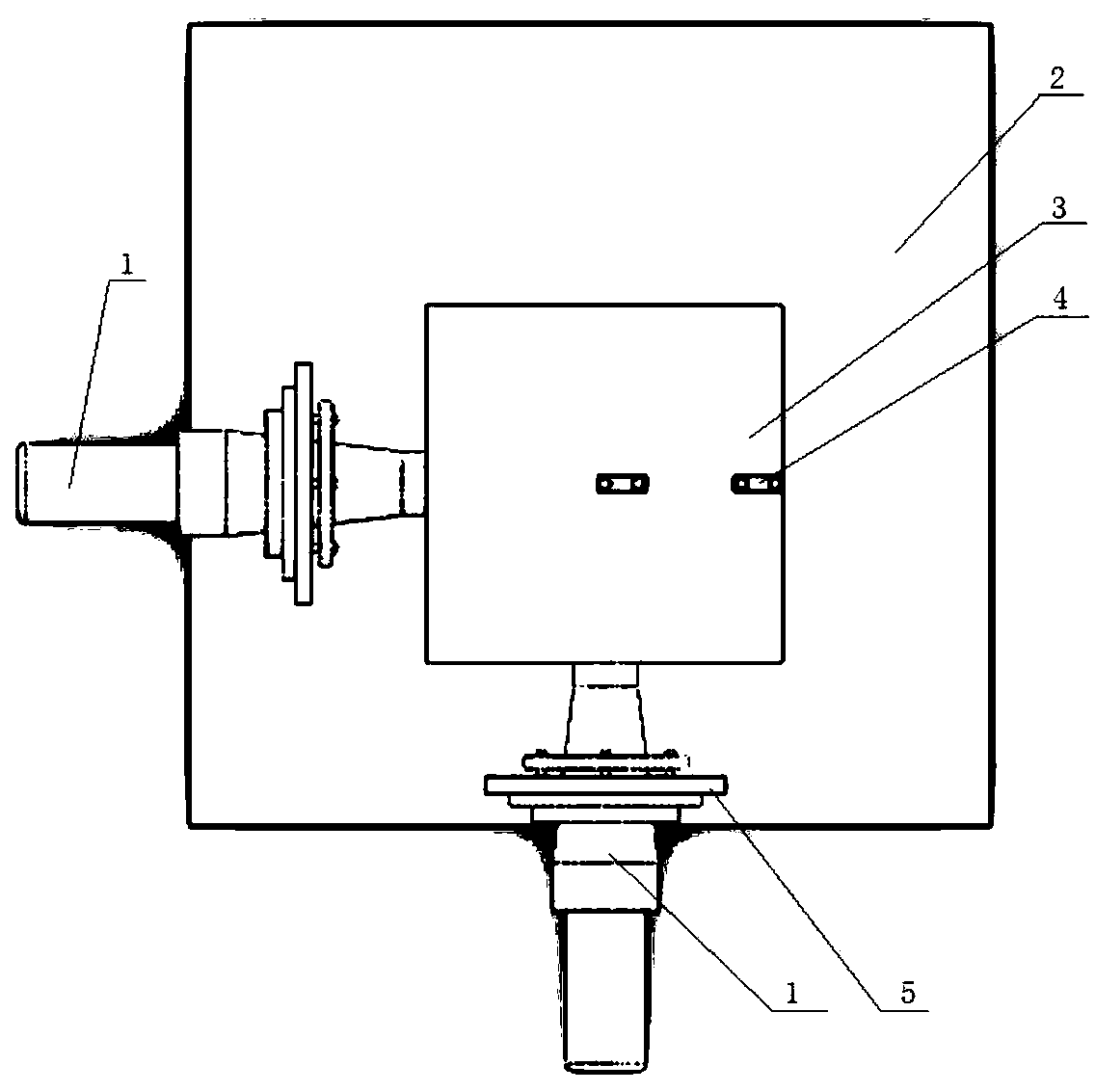

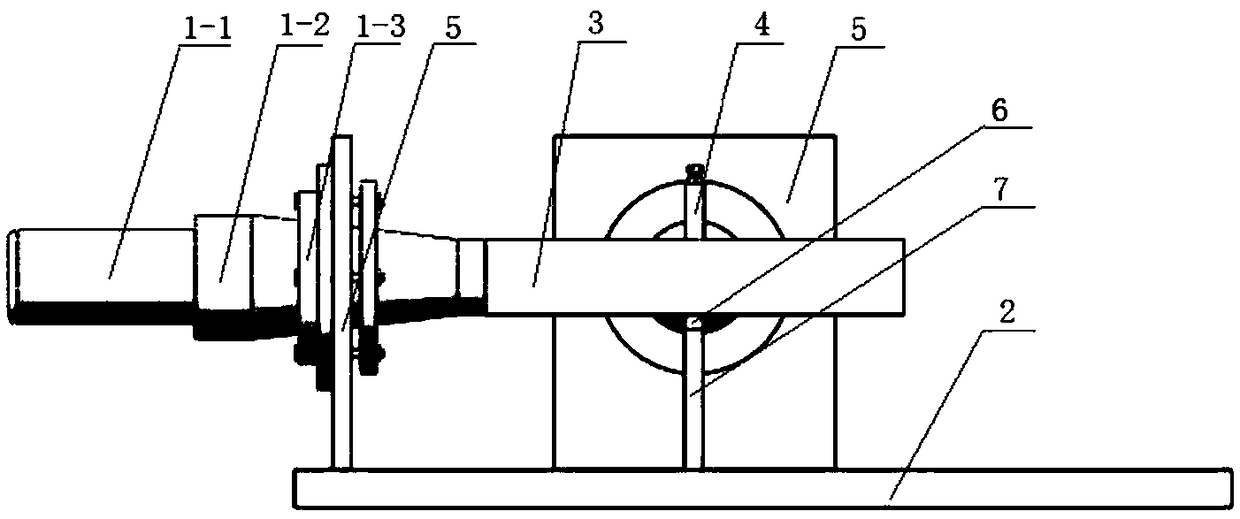

[0029] like figure 1 As shown, the vibrating table supporting frame is installed at the center of the bottom surface of the vibrating table. The vibrating table supporting frame is composed of a column 7 and a supporting ball 6. The supporting ball is fixed on the top surface of the column, and the bottom surface of the column is fixed on the base. The support ball is only in contact with the bottom surface of the vibrating table but is not firmly connected. The column does not press the vibrating table to move upwards, but only provides support in the Z direction.

[0030] The characteristic of this structure is that the supporting frame of the vibrating table and the vibrating table are point supports. Since the contact surface between the supporting frame of the vibrating table and the vibrating table is very close to a point, the energy transmitted by the ultrasonic wave to the supporting frame of the vibrating table will be greatly reduced, and the energy It will be conc...

Embodiment 2

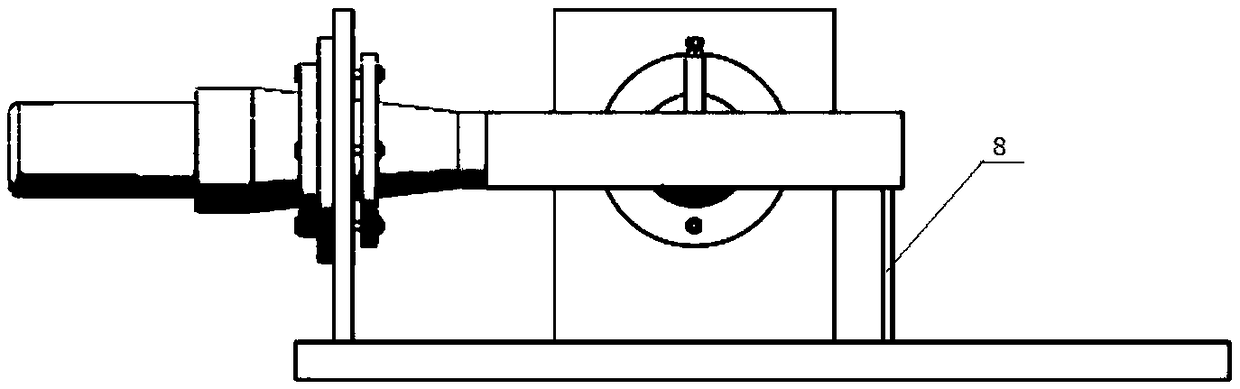

[0032] like image 3 As shown, the vibrating table supporting frame is fixed on one side of the bottom surface of the vibrating table. The vibrating table supporting frame is a support plate 8, the bottom surface of the supporting plate is fixed to the base, and the top surface of the supporting plate only contacts the bottom surface of the vibrating table. But not fixed connection.

[0033] The characteristic of this structure is that: the single support plate of the vibrating table support frame is in contact with the bottom surface of the vibrating table, and the vibrating table supports ultrasonic vibration while the vibrating table support frame does not vibrate. The Z-direction load of the vibration table is supported by a single support plate of the vibration table support frame. This structure is beneficial to reduce the impact of the vibrating table support frame on the overall mode shape of the vibrating table.

[0034] The support plate supporting the vibrating ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com