Vibration punning production method for perlite heat preservation board

A technology of perlite thermal insulation board and production method, which is applied in chemical instruments and methods, cement mixing devices, unloading devices, etc., can solve problems such as the reduction of thermal insulation effect of thermal insulation boards, reduce manual operation, improve efficiency, and improve production. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following is further described in detail through specific implementation methods:

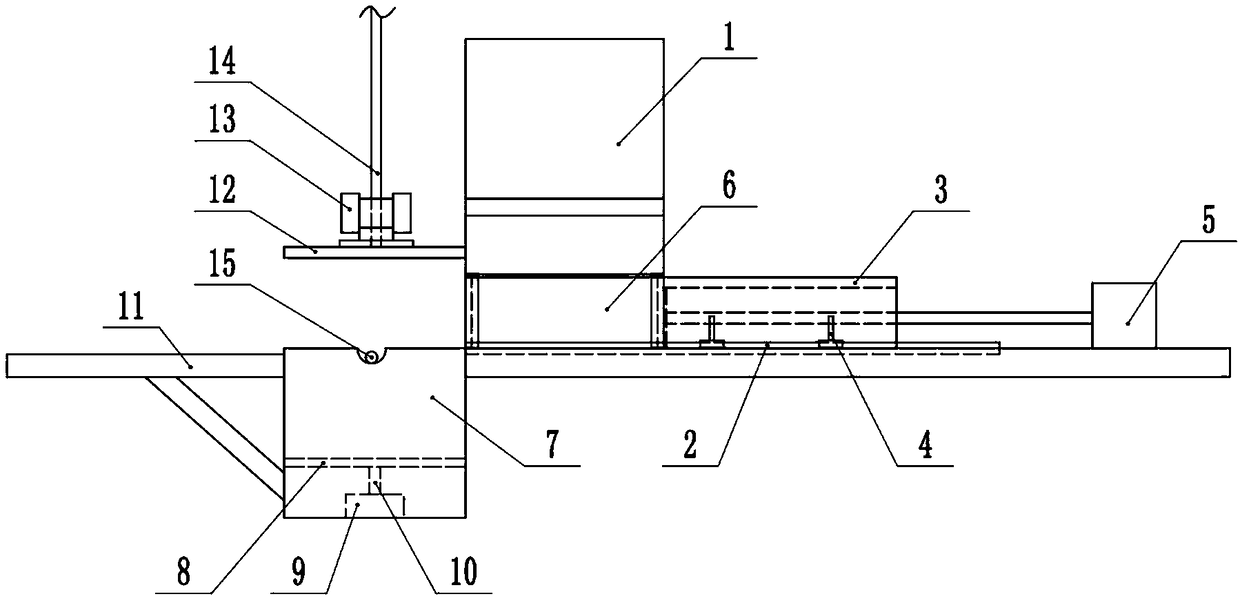

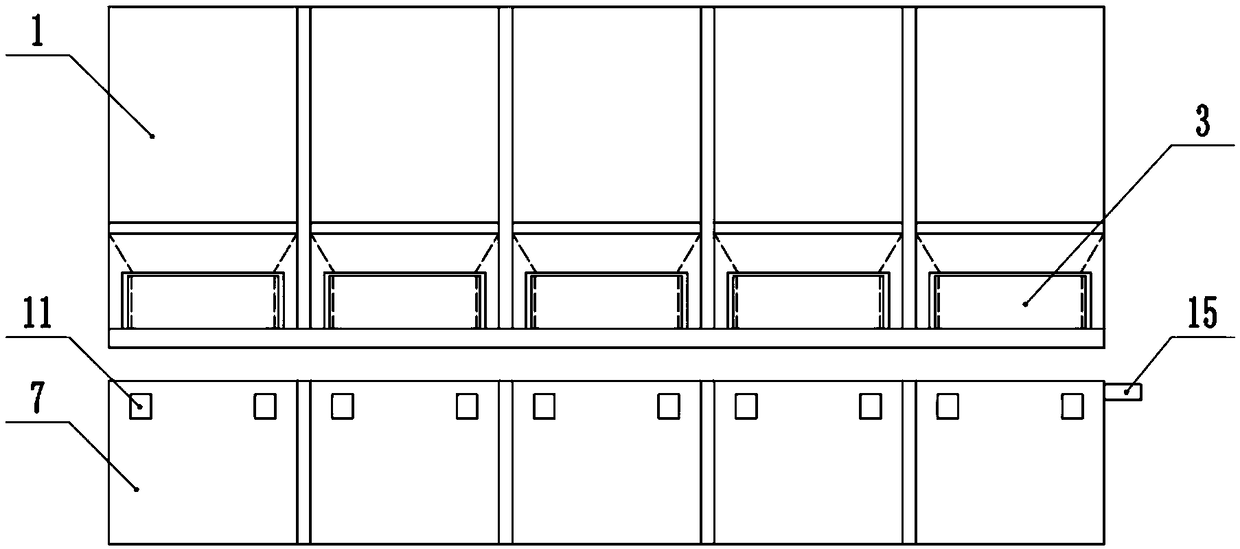

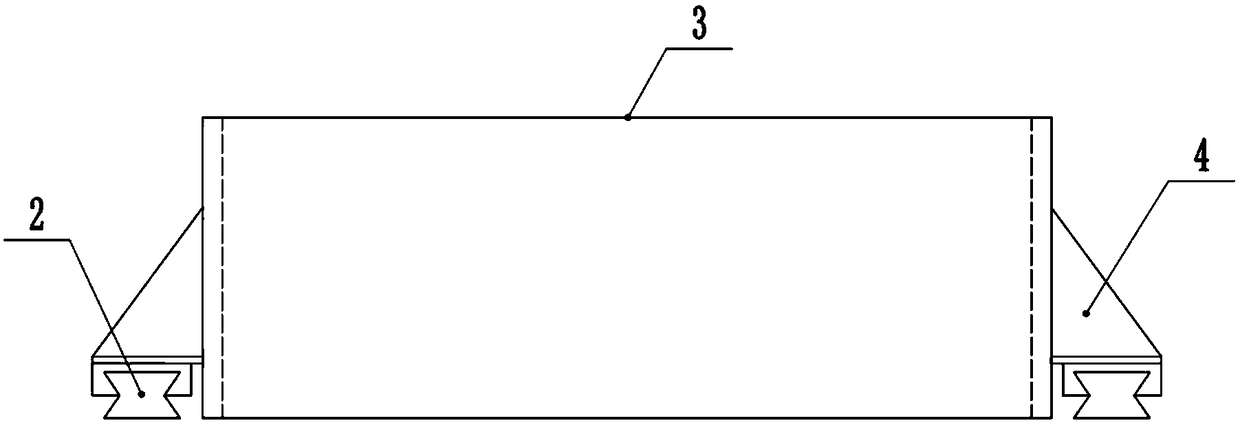

[0027] The reference signs in the accompanying drawings of the description include: storage hopper 1, slide rail 2, material pushing trolley 3, support plate 4, first hydraulic cylinder 5, cavity 6, mold 7, bottom plate 8, second hydraulic cylinder 9, top Rod 10, material guide rod 11, steel plate 12, vibration motor 13, chain 14, limiter 15.

[0028] The embodiment is basically as attached Figure 1 to Figure 3 Shown:

[0029] The vibratory compaction production method of perlite insulation board needs to use a forming and ejecting device for perlite insulation board. The rail 2 and the slide rail 2 are slidably connected with the pusher trolley 3, and the support plate 4 is fixedly connected to the pusher trolley 3, and the support plate 4 is slidably connected with the slide rail 2 through the dovetail groove, and the pusher trolley 3 passes through the first hydraulic cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com