Ultrasonic vibration-assisted injection molding method and device

An ultrasonic vibration and injection molding technology, applied in the coating and other directions, can solve the problem that the molten plastic cannot meet the shrinkage volume of the plastic part, does not solve the problem of clogging the flow resistance of the molten material, and cannot achieve the design target shape, etc., to shorten the injection molding. cycle, reduce injection time, and improve the effect of molding contour accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

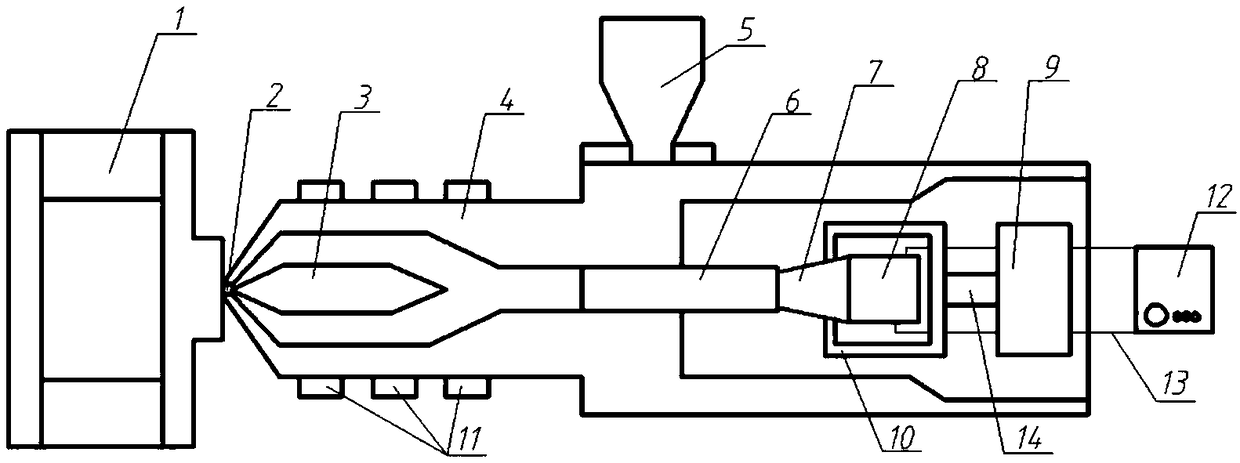

[0033] Embodiment 1 (Ultrasonic Vibration Assisted Plunger Injection Machine Injection Molding)

[0034] Ultrasonic vibration assisted injection molding device, combined with figure 1 As shown, it includes a molding mechanism 1, an injection mechanism and an ultrasonic vibration mechanism. The injection mechanism includes a nozzle 2, a splitter comb 3, a barrel 4, a hopper 5, a plunger 6, a hydraulic device 9 and a heater 11; the ultrasonic vibration mechanism includes a horn 7, a transducer 8, a fixing device 10, a wire 13 and Ultrasonic generator 12.

[0035] The horn 7, the transducer 8 and the fixing device 10 are arranged inside the body of the injection molding machine; the plunger 6 is threaded to the horn 7 through a stud, and the horn 7 is threaded to the transducer 8 through a stud. The transducer 8 is connected to the ultrasonic generator 12 through the wire 13, and the flange of the horn 7 is fixed on the piston rod 14 through the fixing device 10.

[0036] The ...

Embodiment 2

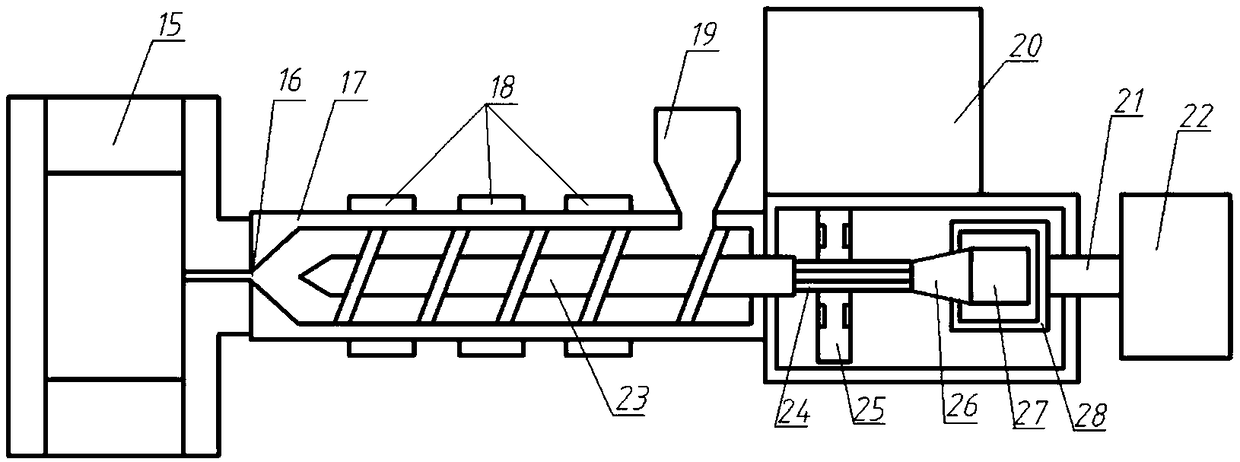

[0039] Embodiment 2 (Ultrasonic Vibration Assisted Screw Injection Machine Injection Molding)

[0040] combined with figure 2 As shown, the device includes a molding mechanism 15, an injection mechanism, a transmission mechanism and an ultrasonic vibration mechanism. The injection mechanism includes a nozzle 16, a barrel 17, a heating ring 18, a hopper 19, a screw 23, a piston rod 21 and a hydraulic device 22; a transmission mechanism includes a gearbox 20, a screw transmission gear 25 and a screw spline 24; the ultrasonic vibration mechanism includes a variable Spindle 26 , transducer 27 and fixture 28 .

[0041] The screw rod 23 is fixedly connected with the screw spline 24, the screw spline 24 is connected with the horn 26, the horn 26 is threaded with the transducer 27 through a stud, and the flange of the horn 26 is fixed on the On the piston rod 21, the screw drive gear 25 is installed on the screw spline 24. The transducer 27 is electrically connected with the ultra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com