A bag-packing mechanism and batch-packing method for neatly arranged roasted eel pieces after roasting

A technology of roasting and roasting eel, applied in the direction of packaging food, wrapping objects, packaging, etc., can solve the problem of unsolved manual loading of materials, and achieve the effect of reducing surface wear and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

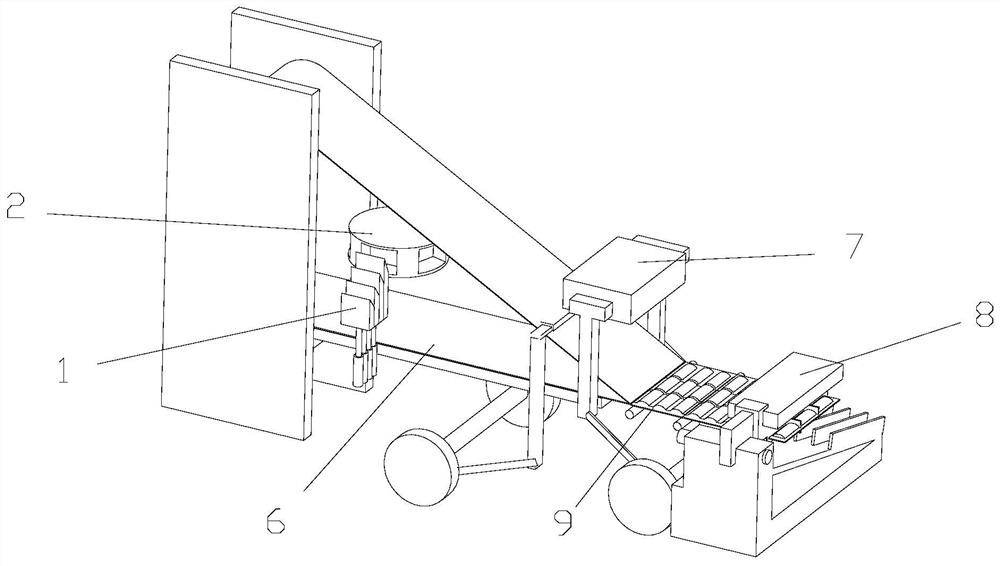

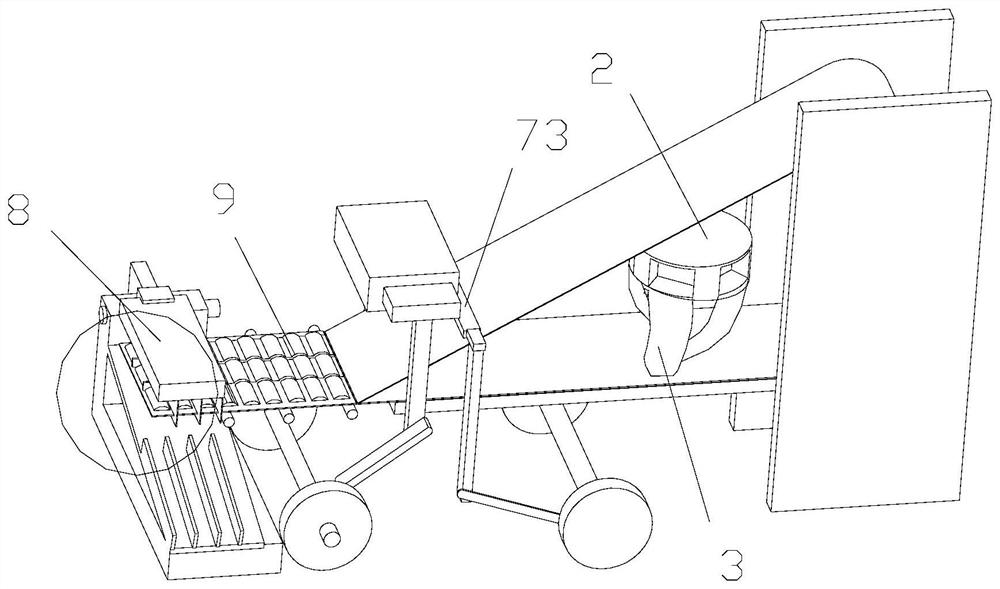

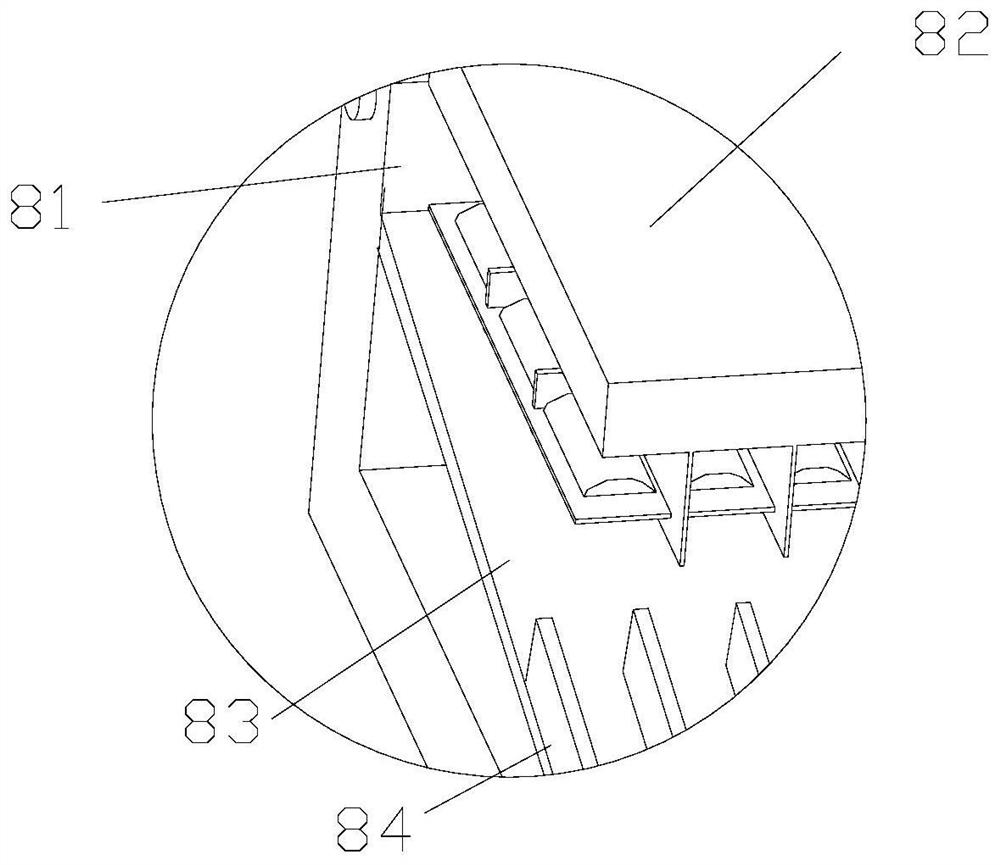

[0052] Such as figure 1 , 2 , 13 shows, this embodiment discloses a roasted eel block neatly arranged in batches into the bag after baking, including a washboard assembly 1, a rotary feeding disc 2, a guide tube 3, an upper film feeding roller 4, a lower Film feeding roller 5, working platform 6, lifting hot pressing part 7, cutting and blanking device 8, conveying platform 9.

[0053] Such as Figure 8 , 9 As shown, the rotary feeding disc 2 includes a disc body, and a feeding bin 21 is opened on the side of the disc body, and a plurality of feeding bins 21 surround the central axis of the disc body at equal intervals to form a ring structure. The bottom of each feed bin 21 is provided with a discharging port, and the discharging port is controlled to open or close by a solenoid valve (not shown in the figure). The washboard assembly 1 is used to feed the roasted eel pieces into the corresponding feeding bin 21 in batches, and one of the feeding bins 21 is also provided with a p...

Embodiment 2

[0061] Such as Figure 5-7 As shown, the difference between this embodiment and the foregoing embodiment is that the washboard assembly 1 includes multiple sets of washboard members, and the washboard members are arranged in order from far to near to the rotary feeding disc 2. Each group of washboards includes a first washboard 11, a second washboard 12 and a lifting device 13. The first washboard 11 and the second washboard 12 have the same structure, and the present invention is introduced with the structure of the first washboard 11 as an object. The first washboard 11 includes a washboard body 111 and a bending plate 112. The top of the washboard body 111 is an inclined surface that gradually decreases in height from left to right. The bending plate 112 includes a first plate body 1121 and a second plate body 1122. The board body 1121 is leaning on the inclined surface, and the second board body 1122 is connected to the right end of the first board body 1121 and inclined u...

Embodiment 3

[0066] Such as Image 6 As shown, the difference between this embodiment and the foregoing embodiment is that the first plate body 1121 is provided with a baffle plate 11211 in the middle section of the top inclined surface. The baffle plate 11211 of the present invention mainly functions as a limiter. Due to the gap between the adjacent washboard bodies 111, the grilled eel block is prevented from sliding down to the gap, which affects the second washboard 12 to move up and down.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com