Garbage can cleaning system and using method thereof

A technology of cleaning system and trash can, applied in the field of garbage trucks, can solve the problems of poor cleaning effect, waste of water, single cleaning method, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

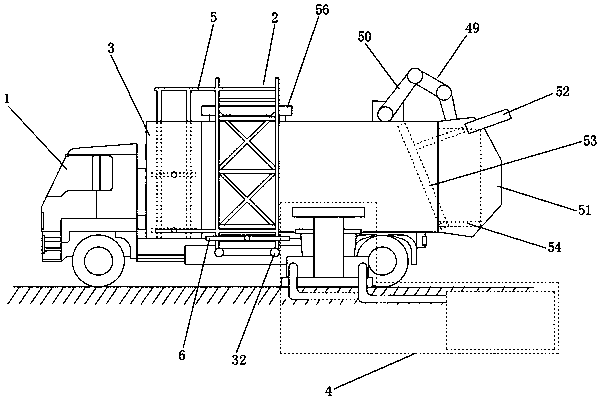

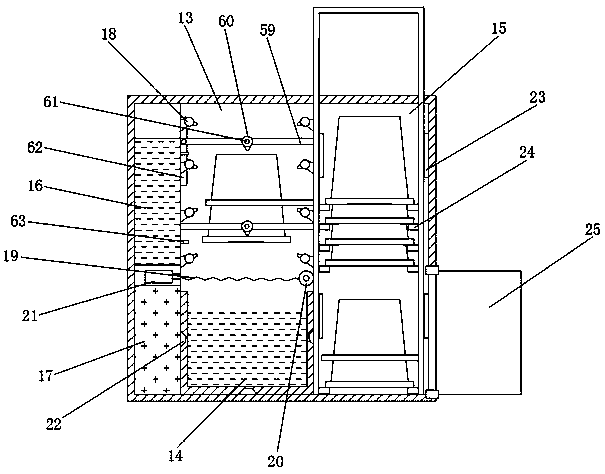

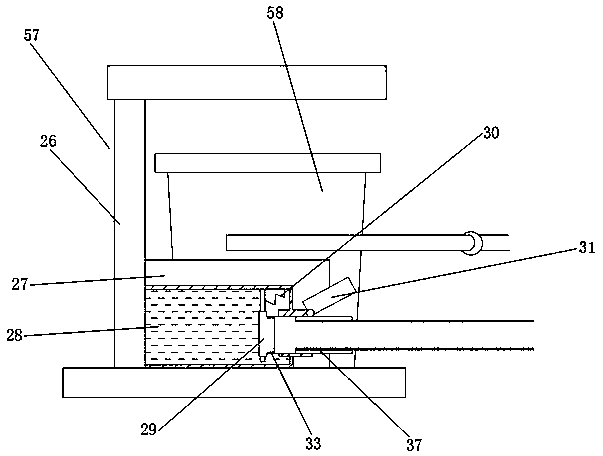

[0040] Embodiment 1: (no anti-slip protrusion 12, no dust cover 31)

[0041] As shown in the accompanying drawings of the description, a garbage can cleaning system includes a car body 1, and also includes a barrel clamping device 2, a cleaning system 3, a sewage purification circulation system 4 and a control system; the top of the car body 1 compartment is provided with a garbage bin The entrance 56 is provided with a garbage compression device 49 at the rear; the cleaning system 3 is arranged at the front end of the car body 1 compartment, close to the garbage inlet 56; the barrel clamping device 2 includes a barrel clamp movable track 5 and a barrel clamp 6 The barrel clip track 5 is a double-track ring-shaped closed track, which is initially arranged on the side of the car body 1 and passes through the cleaning system 3; the barrel clip 6 has two groups, which are placed horizontally on the barrel clip In the middle of the movable track 5; the cleaning system 3 includes a...

Embodiment 2

[0051] Embodiment 2: (with anti-slip protrusion 12, without dust cover 31)

[0052] The second embodiment is basically the same in structure and principle as the first embodiment, except that the bucket clip 6 also includes anti-slip protrusions 12; The anti-slip protrusion 12 plays an anti-skid role when the trash can 58 is clamped.

Embodiment 3

[0053] Embodiment 3: (without anti-skid protrusion 12, with dustproof cover 31)

[0054] Embodiment 3 is basically the same in structure and principle as Embodiment 1, except that a dustproof cover 31 is hinged at the front ends of the clean water port 28 and the sewage port 38 . The dustproof cover 31 acts as a dustproof function for the clean water port 28 and the sewage port 38 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com