High heat conductivity and low shrinking rate type polyolefin composite material and preparation method thereof

A low-shrinkage, composite material technology, applied in the field of polymer materials, can solve the problems of ordinary polyolefin thermal conductivity and dimensional stability that cannot meet specific needs, achieve good dimensional stability, reduce linear expansion coefficient, and good thermal conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

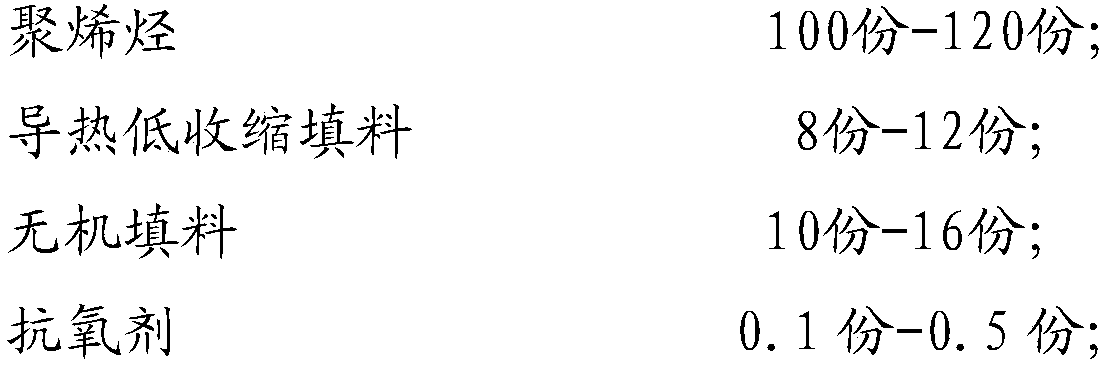

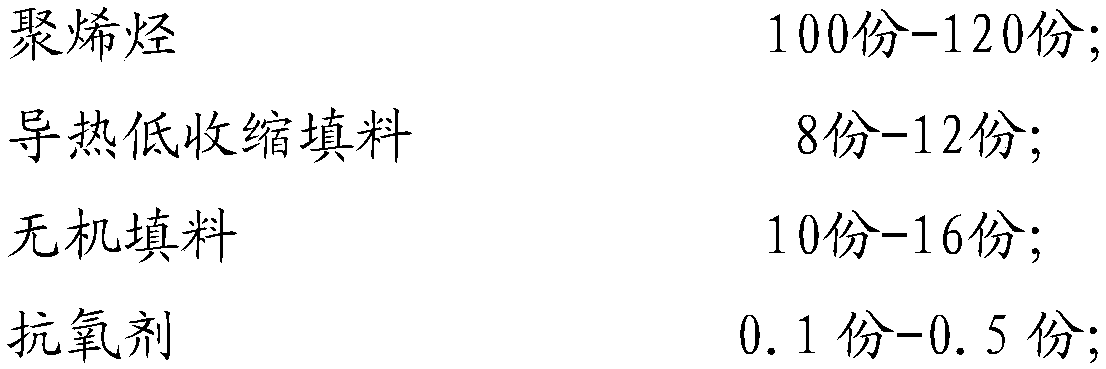

[0038] The preparation method of any one of the above-mentioned polyolefin composite materials with high thermal conductivity and low shrinkage rate comprises the following steps:

[0039] (1) Weigh 100-120 parts of polyolefin, 8-12 parts of thermally conductive low-shrinkage filler, 10-16 parts of inorganic filler, 0.1-0.5 part of antioxidant, mix and stir evenly to obtain a mixture;

[0040] (2) extruding and granulating the mixture obtained in step (1) to obtain a polyolefin composite material.

Embodiment 1

[0042] (1) Weigh 100 parts of PP, 8 parts of thermally conductive low-shrinkage filler, 10 parts of calcium carbonate, and 0.1 part of Irganox1010, mix and stir evenly to obtain a mixture;

[0043] (2) Extrude and granulate the mixture obtained in step (1) to obtain PP composite material P1.

[0044] Among them, the temperature and screw speed of each zone of the twin-screw extruder are respectively: the temperature of the first zone is 170°C, the temperature of the second zone is 230°C, the temperature of the third zone is 230°C, the temperature of the fourth zone is 230°C, the temperature of the fifth zone is 230°C, and the temperature of the sixth zone is 230°C. The zone temperature is 230°C, the head temperature is 230°C, and the screw speed is 220r / min.

Embodiment 2

[0054] (1) Weigh 120 parts of PE, 12 parts of thermally conductive low-shrinkage filler, 16 parts of talcum powder, 0.1 part of Irganox1010, 0.2 part of Irganox1330, 0.2 part of Irganox168 and mix them evenly to obtain a mixture;

[0055] (2) Extruding and granulating the mixture obtained in step (1) to obtain PE composite material P2.

[0056] Among them, the temperature and screw speed of each zone of the twin-screw extruder are respectively: the temperature of the first zone is 120°C, the temperature of the second zone is 180°C, the temperature of the third zone is 180°C, the temperature of the fourth zone is 180°C, the temperature of the fifth zone is 180°C, and the temperature of the sixth zone is 180°C. The zone temperature is 180°C, the head temperature is 180°C, and the screw speed is 300r / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com