Advanced drilling tool

A technology of advanced drilling and drill bits, applied in drill bits, drilling equipment, earthwork drilling, etc., can solve the problem of low core coring integrity rate, and achieve the effect of ensuring the integrity rate, ensuring the recovery rate, and reducing scour

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

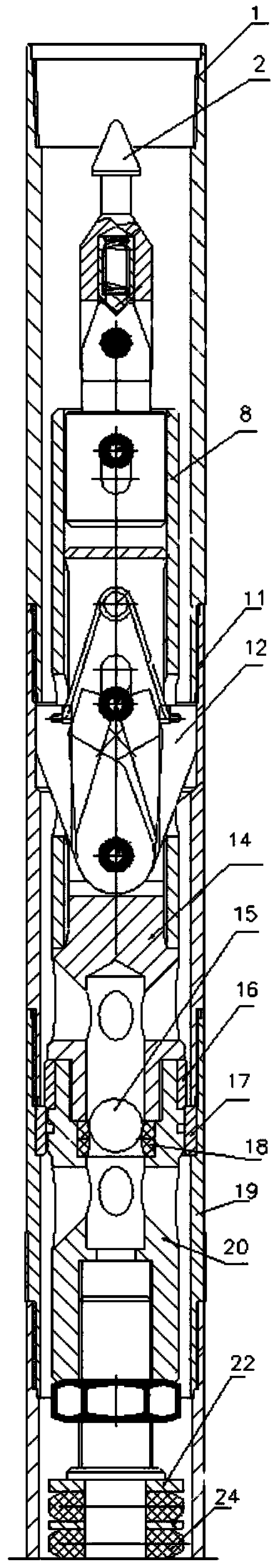

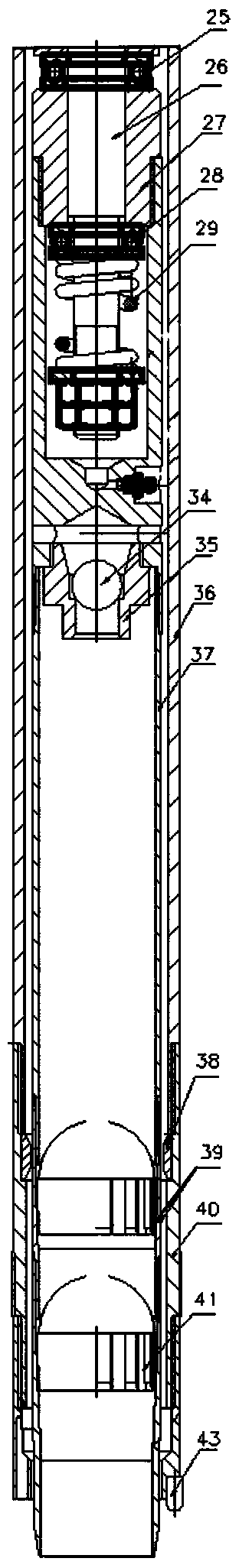

[0039] A kind of advance drilling tool, comprises inner pipe 37 assembly and outer pipe 36 assembly, and described outer pipe 36 assembly comprises bullet stop head 1, bullet chamber 11, seat ring 17, reamer, outer pipe 36 and Drill bit 43; the inner tube 37 assembly includes fishing spear head 2, recovery pipe 8, bullet caliper 12, suspension cup 16, in-position reporting mechanism, blocked signaling mechanism and inner tube 37, and the lower end of the inner tube 37 exceeds the lower end of the drill bit 43 The lower part of the inner tube 37 is provided with a lower stop spring 41 and an upper stop spring 39 .

[0040] The lower end of the inner tube 37 is 20 to 25 mm beyond the lower end of the drill bit 43 .

[0041] The reamers include an upper reamer 19 and a lower reamer 40 .

[0042]The upper end of the recovery pipe 8 is connected to the spear head 2, the lower end of the recovery pipe 8 is connected to the bullet caliper 12, and the bullet caliper 12 cooperates wit...

Embodiment 2

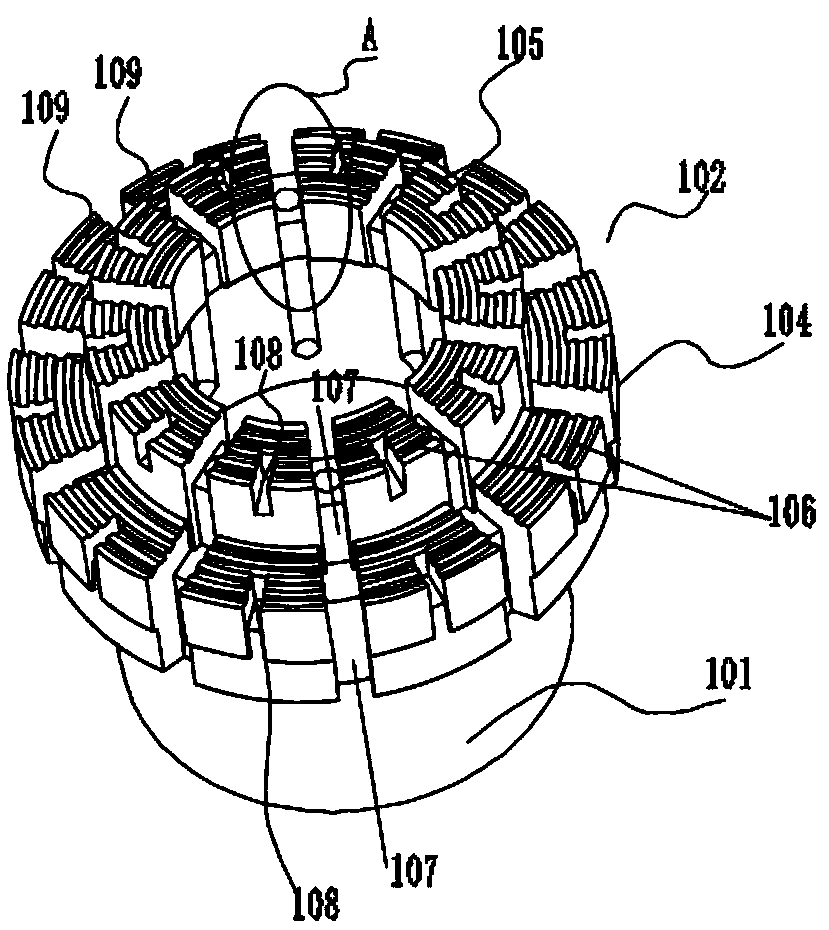

[0054] like Figure 3-Figure 8 As shown, to further optimize the embodiment, the drill bit 43 is a step-shaped drill bit 43, specifically a two-stage drill bit 43, including an outer tube connecting sleeve 101 and an annular drill bit 43 arranged in sequence from the inside to the outside. , the outer pipe connection sleeve 101 and the drill bit 43 are connected through a transition bonding pipe 103; the drill bit 43 includes a second-stage drill bit 104 and a first-stage drill bit 105 from the inside to the outside, and the outer diameter of the first-stage drill bit 105 Smaller than the outer diameter of the second-stage drill bit 104; the second-stage drill bit 104 and the first-stage drill bit 105 are connected to form a coaxial stepped drill bit 43, and the second-stage drill bit 104 and the first-stage drill bit 104 The drill bit 105 is composed of a plurality of cutting teeth 106 of equal height, and the plurality of cutting teeth 106 are evenly distributed around the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com