Integrated deep sea hydraulic power source

A hydraulic power source, integrated technology, applied in the direction of fluid pressure actuation device, fluid pressure actuation system components, fuel supply tank device, etc., can solve the problems of large volume and weight, low reliability, system dispersion, etc. Small, large effective compensation, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following describes specific embodiments of the present invention.

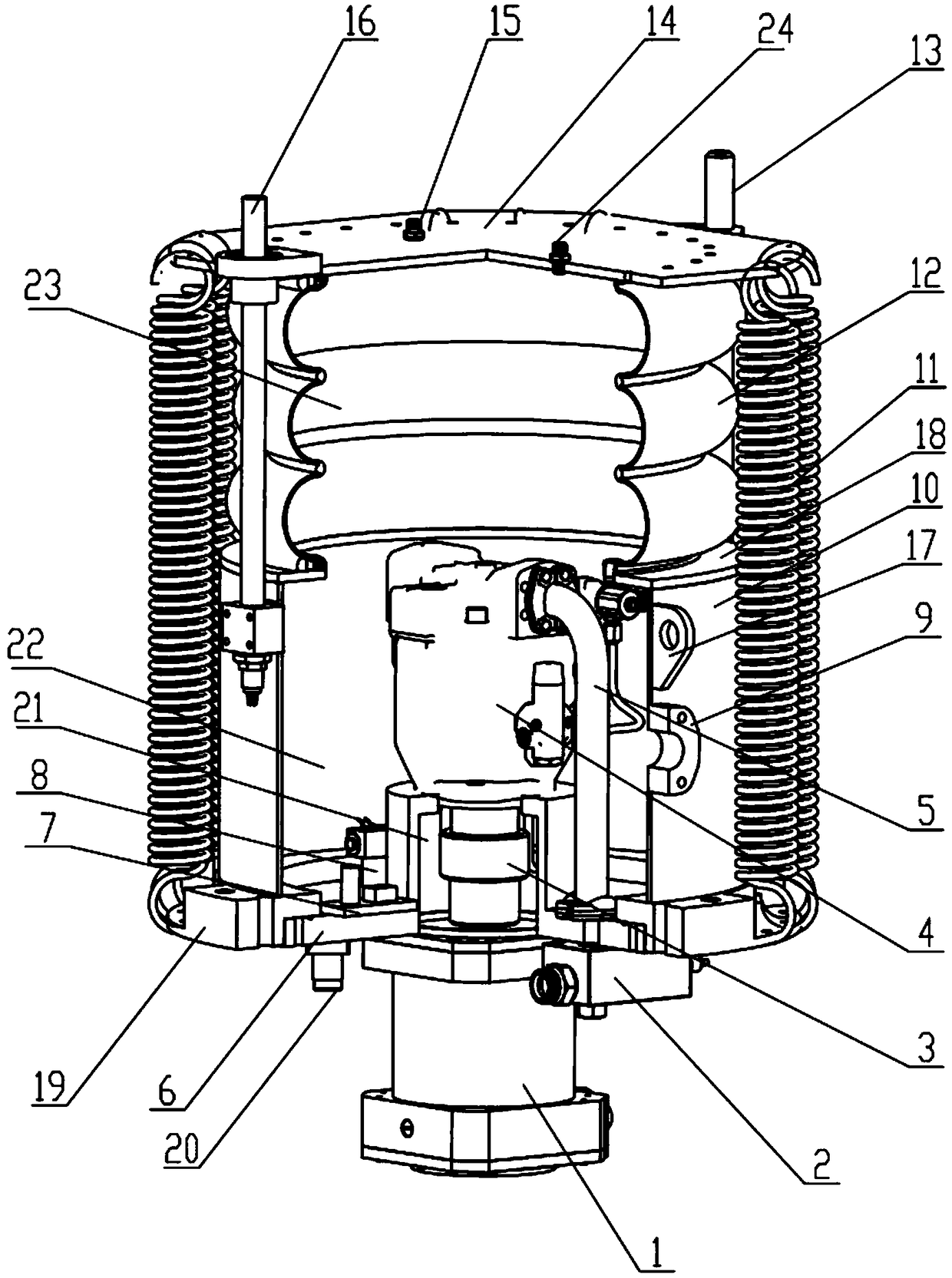

[0025] Such as figure 1 As shown, the integrated deep-sea hydraulic power source includes a deep-sea motor 1, which is a pressure-compensated structure motor, specifically any one of a brushless DC motor, a permanent magnet synchronous motor, or an induction motor. The output end of the deep-sea motor 1 is connected to the oil pump 4 through the coupling 3, and a bell is arranged at the connection between the coupling 3 and the oil pump 4 and the periphery of the coupling 3, and openings are evenly distributed along the outer circumference of the bell. The oil tank bottom plate 6 is connected to form an integrated structure. The first cavity 21 is formed between the oil pump 4 and the deep sea motor 1 inside the integrated structure; an oil tank 10 is arranged on the periphery of the oil pump 4, and one end of the oil tank 10 passes through an oil tank mounting flange 19 is fixed to the surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com