Easy-to-accommodate heat insulation fabric layer structure

A technology of insulating cloth and layer structure, which is applied in the direction of cloth feeding mechanism, protection pipes through heat insulation, heat exchange equipment, etc. Mass production applications, isolation of heat transfer, heat loss reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

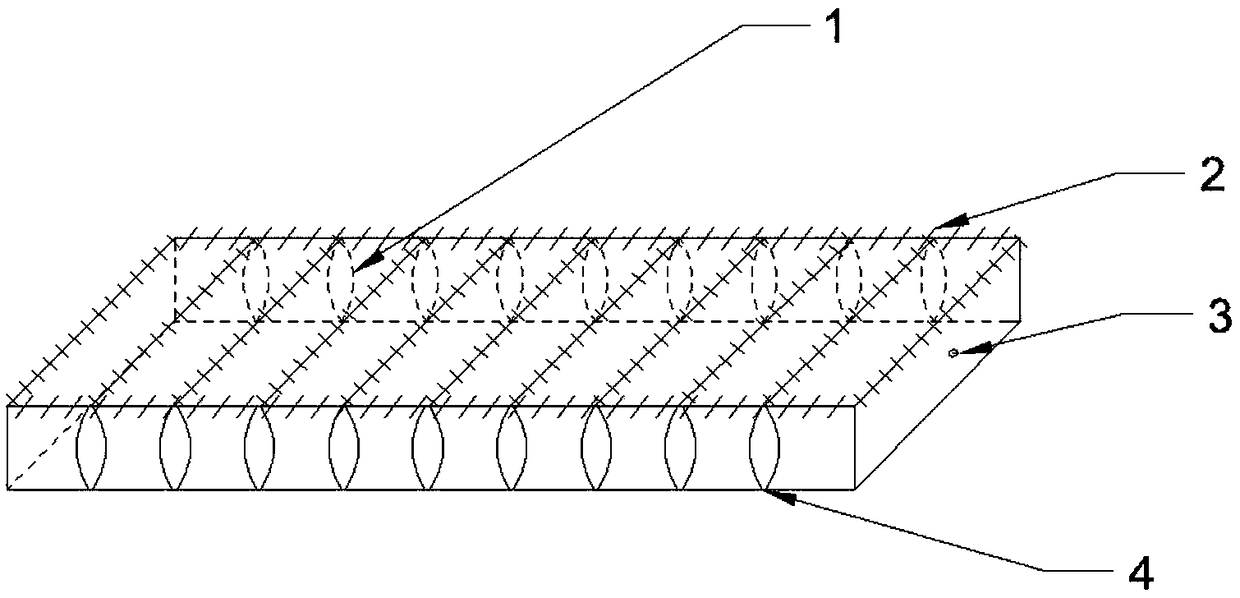

[0022] The invention provides a structure of heat insulation cloth layer structure, such as figure 1 As shown, a preferred embodiment of the present invention is shown, specifically, the outer layer of the heat-insulating cloth layer structure is a sealed cavity structure made of waterproof cloth 1 after cutting and sewing, and the waterproof cloth 1 The cat hair yarn 4 is sewn into the sealed cavity structure, the two ends of the cat wool yarn 4 are sewn on the upper and lower sides of the sealed cavity structure and multiple partitions are formed inside the sealed cavity structure, and the waterproof cloth 1 is provided with an air nozzle 3. The air nozzle 3 is fixed on the waterproof fabric 1 by gluing and sealed with a sealant, and the waterproof fabric 1 and the waterproof fabric 1, and between the waterproof fabr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com