Wear-resistant middle plate of middle groove of scraper conveyor with low friction coefficient and production method of wear-resistant middle plate

A scraper conveyor, low friction coefficient technology, used in conveyors, transportation and packaging, coating and other directions, can solve the problems of increasing the noise and motor power of scraper conveyors, harsh working environment, and increased surface friction coefficient. The effect of high production efficiency, simple production method and excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] When the present invention is concretely implemented, comprise the following steps:

[0029] 1) Surface treatment of the main body 1 of the center plate to remove oil, oxide and rust impurities on the surface;

[0030] 2) Turn on the CNC plasma middle tank cladding equipment, adjust the air pressure to 0.25~0.5MPa, adjust the flow rate of argon gas to 9L / min, and adjust the flow rate of cooling water to 0.7m 3 / h, adjust the powder feeding speed to 45g / min, adjust the cladding power supply current to 230A, and the cladding speed to 360mm / min;

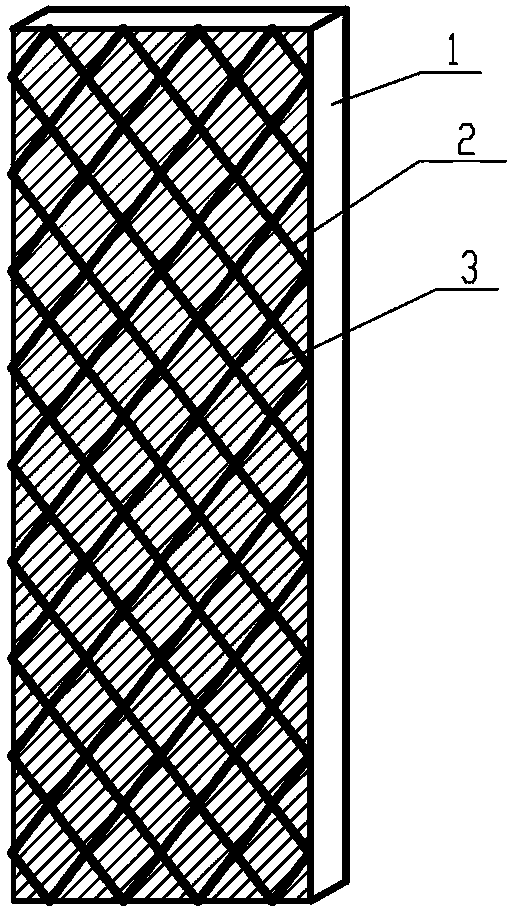

[0031] 3) On the surface of the main body 1 of the middle plate, a grid-shaped alloy wear-resistant layer 2 that is firmly connected together is clad, so that each grid of the alloy wear-resistant layer 2 has a height of 2-3mm and a width of 8-12mm evenly distributed on the middle plate body 1 surface;

[0032] 4) Spread the anti-friction coating material evenly on the grid of the alloy wear-resistant layer 2 to form the anti-f...

Embodiment 2

[0039] When the present invention is concretely implemented, comprise the following steps:

[0040] 1) Surface treatment of the main body 1 of the center plate to remove oil, oxide and rust impurities on the surface;

[0041] 2) Turn on the CNC plasma middle tank cladding equipment or the plasma filling wire injection cladding device with the patent number ZL201721247893.5, adjust the air pressure to 0.25~0.5MPa, adjust the argon gas flow rate to 8L / min, and adjust the cooling water flow rate to 0.9 m 3 / h, adjust the powder feeding speed to 35g / min, adjust the cladding power supply current to 250A, and the cladding speed to 330mm / min;

[0042] 3) On the surface of the main body 1 of the middle plate, a grid-shaped alloy wear-resistant layer 2 that is firmly connected together is clad, so that each grid of the alloy wear-resistant layer 2 has a height of 2-3mm and a width of 8-12mm evenly distributed on the middle plate body 1 surface;

[0043] 4) Spread the anti-friction c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap