Hydrogen production method and device with magnesium hydride as hydrogen storage material

A hydrogen storage material and hydrogen production device technology, applied in the field of hydrogen production, can solve problems such as damage or combustion, affect the quality of hydrogen, and damage the life of fuel cells, so as to promote the hydrolysis reaction, shorten the start of the reaction, and prevent the loss of reaction heat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

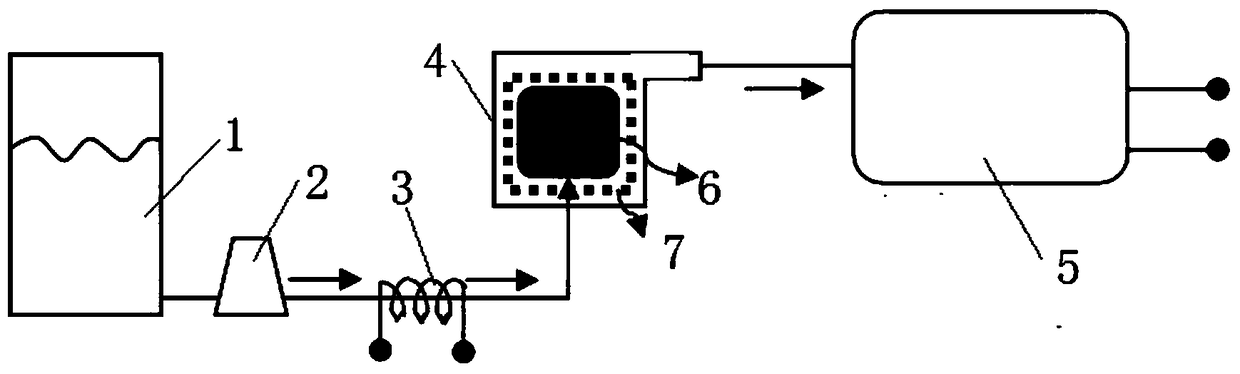

[0035] refer to figure 1, In an embodiment of the present invention, a hydrogen production device using magnesium hydride as a hydrogen storage material includes a water tank 1 , a water pump 2 , a steam generator 3 , and a reaction chamber 4 . The water tank 1 is connected to the water pump 2 through a pipeline, and the water pump 2 is connected to the reaction chamber 4 through a pipeline. The pipeline between the water pump 2 and the reaction chamber 4 is provided with a steam generator 3, and the reaction chamber 4 is connected to the fuel cell. 5 are connected by pipelines, and the reaction chamber 4 is provided with a block-shaped magnesium hydride filler layer 6, and the block-shaped magnesium hydride filler layer 6 is formed by stacking block-shaped magnesium hydride, and the block-shaped magnesium hydride is granular or cake-shaped, Blocky magnesium hydride is mixed and pressed by MgH2 and other chemical substances (M), M is one of Al, Mg, Zn or Fe, the inner wall of ...

Embodiment 2

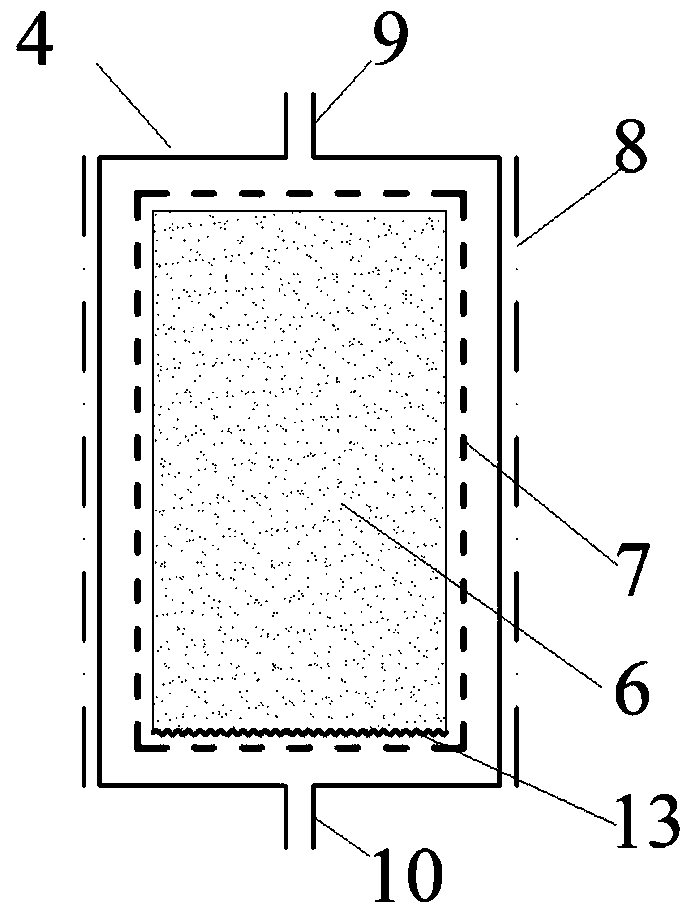

[0042] refer to figure 2 , In an embodiment of the present invention, a hydrogen production device using magnesium hydride as a hydrogen storage material includes a water tank 1 , a water pump 2 , a steam generator 3 , and a reaction chamber 4 . The water tank 1 is connected to the water pump 2 through a pipeline, and the water pump 2 is connected to the reaction chamber 4 through a pipeline. The pipeline between the water pump 2 and the reaction chamber 4 is provided with a steam generator 3, and the reaction chamber 4 is connected to the fuel cell. 5 are connected by pipelines, the inner wall of the reaction chamber 4 is wrapped with a 1-50 mm thick porous heat insulating material 7, the upper and lower ends of the reaction chamber 4 are placed with a 1-50 mm thick porous heat insulating material 7, and the two ends of the reaction chamber 4 are respectively A hydrogen outlet 9 and a steam inlet 10 are set, and a thermal insulation material 8 is arranged outside the reactio...

Embodiment 3

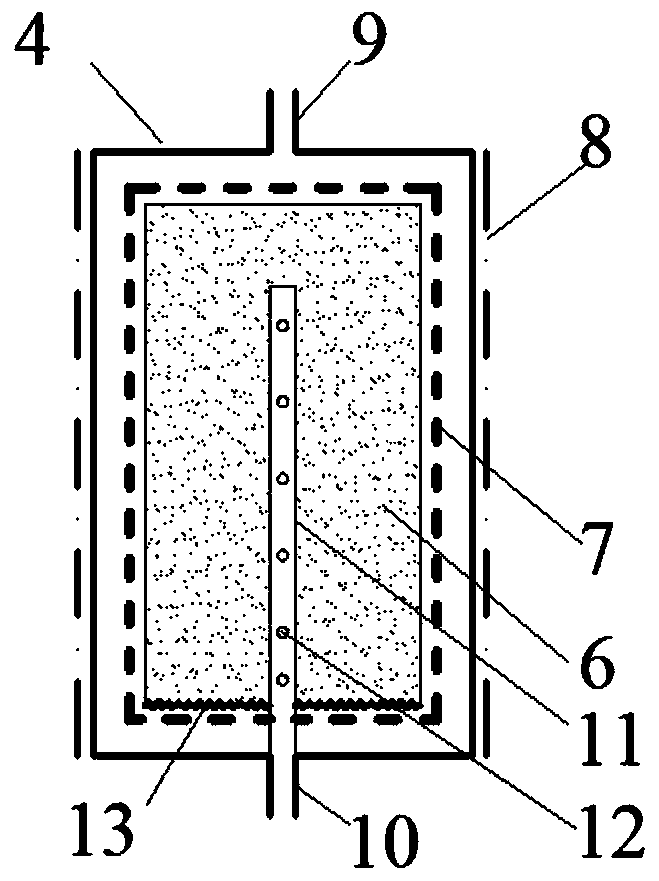

[0049] refer to image 3 , in an embodiment of the present invention, a hydrogen production device using magnesium hydride as a hydrogen storage material includes a water tank 1, a water pump 2, a heater 3, and a reaction chamber 4. The water tank 1 is connected to the water pump 2 through a pipeline, and the The water pump 2 is connected to the reaction chamber 4 through a pipe, a steam generator 3 is arranged on the pipe between the water pump 2 and the reaction chamber 4, and the reaction chamber 4 is connected to the fuel cell 5 through a pipe. The inner wall of the reaction chamber 4 is wrapped with a 1-50mm thick porous insulating material 7, and the upper and lower ends of the reaction chamber 4 are placed with a 1-50mm thick porous insulating material 7, and the two ends of the reaction chamber 4 are respectively provided with a hydrogen outlet 9 and a The steam inlet 10, the heat insulation material 8 is arranged outside the reaction chamber 4, the porous mesh materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com