A multi-structure composite material preform and its composite forming manufacturing method

A composite material and composite forming technology, which is applied in chemical instruments and methods, lamination auxiliary operations, metal layered products, etc., can solve the problems of single material system and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

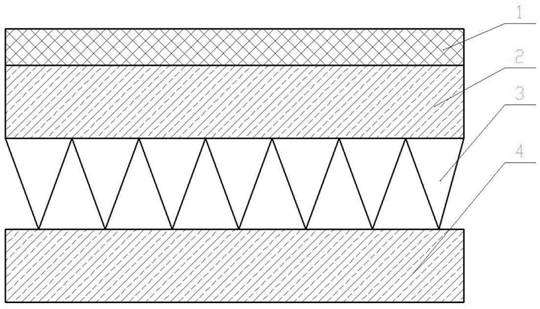

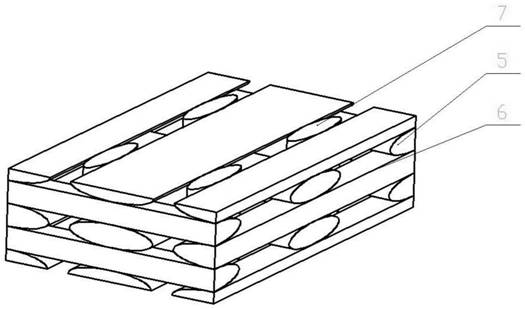

[0032]EXAMPLES: Multi-structure composite prefabrication with a space, 80 mm thick, and a height of 120 mm. The upper woven structure has a thickness of 16mm, X to yarn, Y to the yarn, the fiber specification T300 3K, the layer density 40 layers / cm; Z to the yarn selected carbon fiber, fiber specification T300 6K, 2 joint, Z to the center of the wire 2.0mm from. The bottom layer has a thickness of 10 mm, X-direction fiber, Y to fibers, silicon carbide fibers, fibers 6K, layer density 16 layers / cm; Z to fibers, carbon fibers, fibers T3006K, and Z to 3.0 mm. The medium-level dot matrix structure has a thickness of 50 mm, and the fibers are selected for carbon fibers, and the fiber specification T300 3K, the thermoplastic resin is used to select polypropylene, and the dot matrix type is X-type. Outer short fiber structure thickness 4mm, carbon fiber felt 50g / m2The metal short fiber mass content is 4.1%, and the silicon carbide short fiber mass content is 9.7%.

[0033]Specific imple...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com