Waterproof coiled material and preparation method thereof

A technology for waterproofing membranes and waterproofing materials, applied in chemical instruments and methods, lamination devices, lamination, etc., can solve the problems of fire resistance, no flame retardant effect, and increased cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

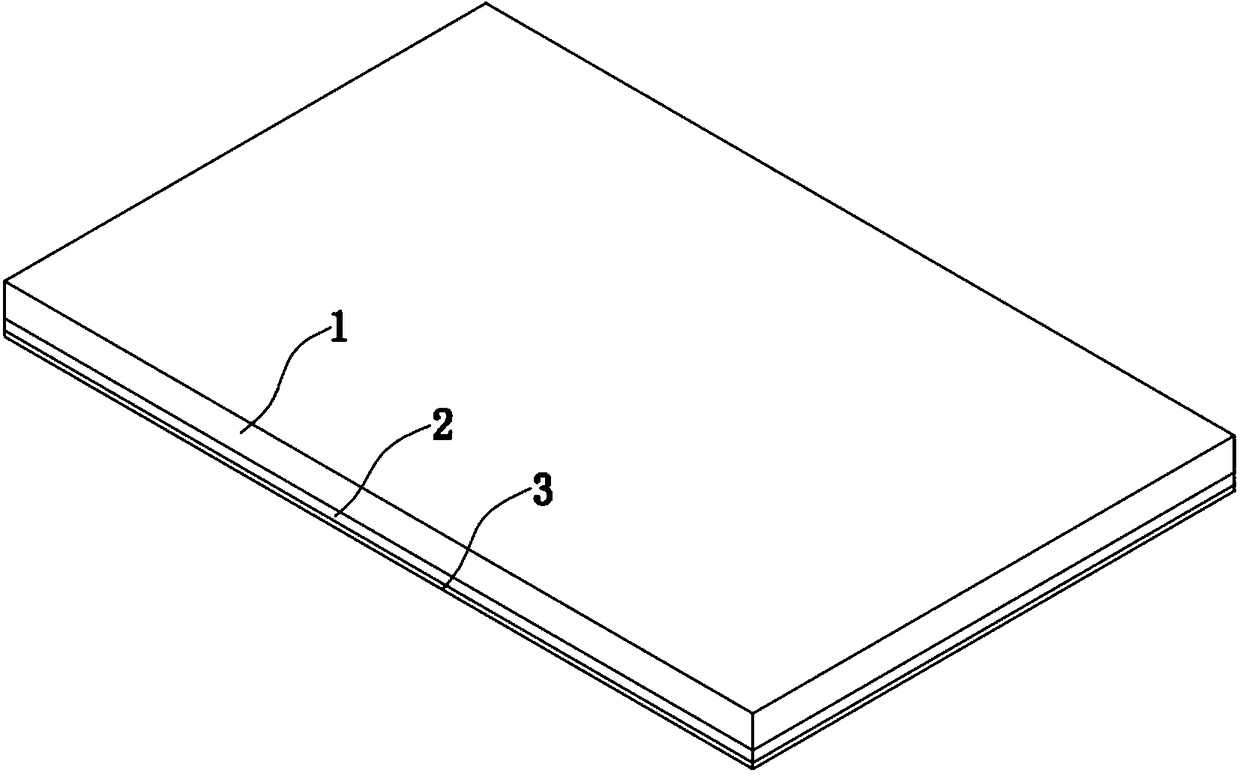

[0026] A waterproof coiled material, comprising a first waterproof layer, a base layer is bonded to the lower part of the first waterproof layer, and a second waterproof layer is bonded to the lower part of the base layer.

[0027] Specifically, the first waterproof layer and the second waterproof layer are made of the same mixed material.

[0028] Specifically, the thickness of the first waterproof layer is 4 mm, the thickness of the base layer is 1 mm, and the thickness of the second waterproof layer is 1 mm.

[0029] A preparation method of a waterproof coiled material, specifically according to the following steps:

[0030] S1: Preparation of modified asphalt. Coal tar pitch is heated to 250°C in a heating furnace, and then put into the oxidation tower for oxidation treatment. Before oxidation treatment in the oxidation tower, diatomite powder is put into the oxidation tower. The diatomite is made of Raymond mill Grinding with a powder machine to obtain diatomite powder w...

Embodiment 2

[0037] A waterproof coiled material, comprising a first waterproof layer, a base layer is bonded to the lower part of the first waterproof layer, and a second waterproof layer is bonded to the lower part of the base layer.

[0038] Specifically, the first waterproof layer and the second waterproof layer are made of the same mixed material.

[0039] Specifically, the thickness of the first waterproof layer is 6 mm, the thickness of the base layer is 1.25 mm, and the thickness of the second waterproof layer is 1 mm.

[0040] A preparation method of a waterproof coiled material, specifically according to the following steps:

[0041] S1: Preparation of modified asphalt. Coal tar pitch is heated to 250°C in a heating furnace, and then put into the oxidation tower for oxidation treatment. Before oxidation treatment in the oxidation tower, diatomite powder is put into the oxidation tower. The diatomite is made of Raymond mill Grinding with a powder machine to obtain diatomite powde...

Embodiment 3

[0048] A waterproof coiled material, comprising a first waterproof layer, a base layer is bonded to the lower part of the first waterproof layer, and a second waterproof layer is bonded to the lower part of the base layer.

[0049] Specifically, the first waterproof layer and the second waterproof layer are made of the same mixed material.

[0050] Specifically, the thickness of the first waterproof layer is 5 mm, the thickness of the base layer is 1.5 mm, and the thickness of the second waterproof layer is 1 mm.

[0051] A preparation method of a waterproof coiled material, specifically according to the following steps:

[0052] S1: Preparation of modified asphalt. The petroleum asphalt is heated to 265°C by a heating furnace, and then put into the oxidation tower for oxidation treatment. Before the oxidation treatment in the oxidation tower, diatomite powder is put into the oxidation tower. The diatomite is made of Raymond mill Grinding with a powder machine to obtain diato...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com