Prefabricated assembling reinforced concrete component delivery device

A reinforced concrete, prefabricated assembly technology, used in transportation and packaging, internal accessories, containers to prevent mechanical damage, etc., can solve problems such as concrete damage, affecting construction quality, and environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the examples, which are only used to explain the present invention, and do not constitute a limitation to the protection scope of the present invention.

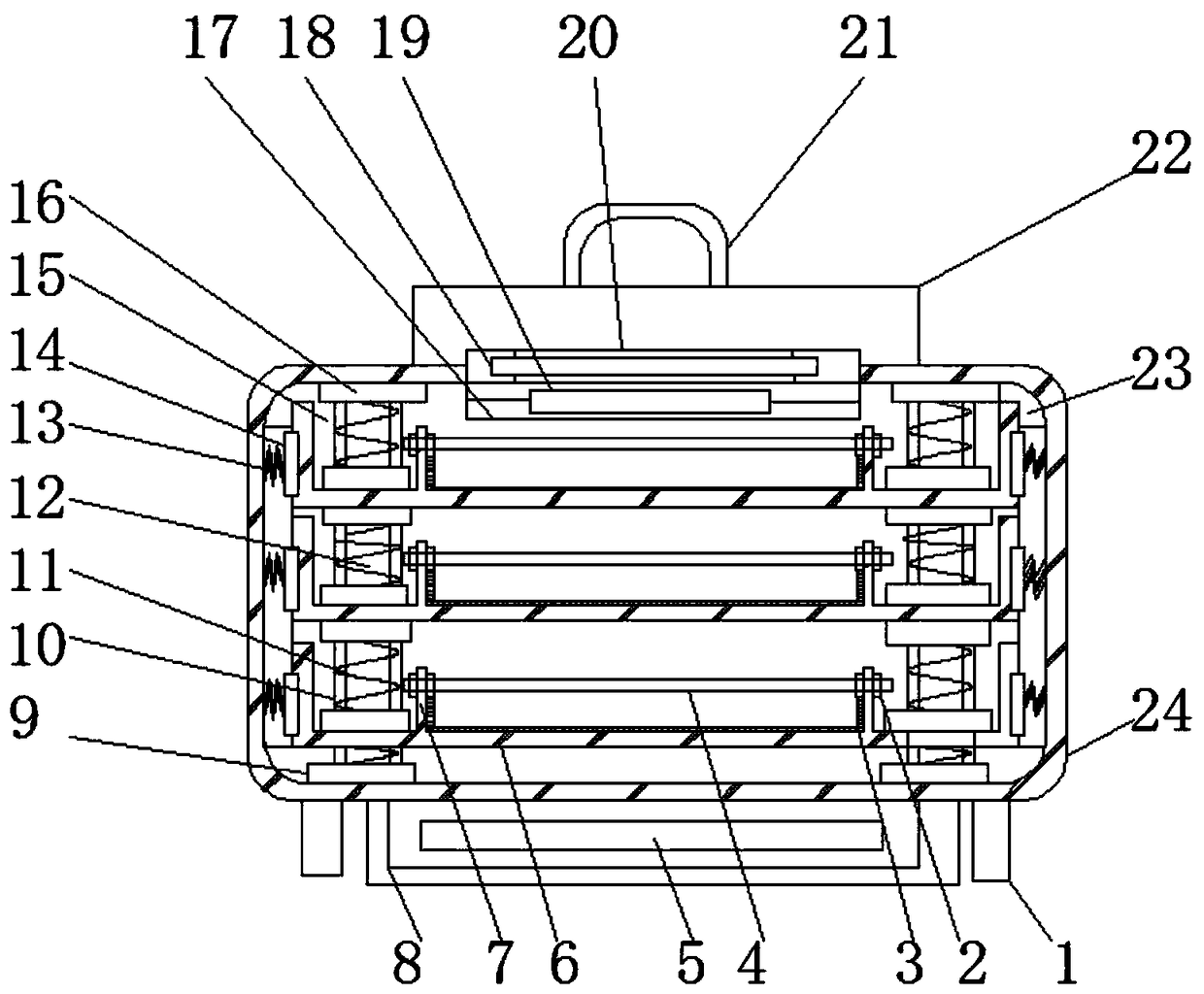

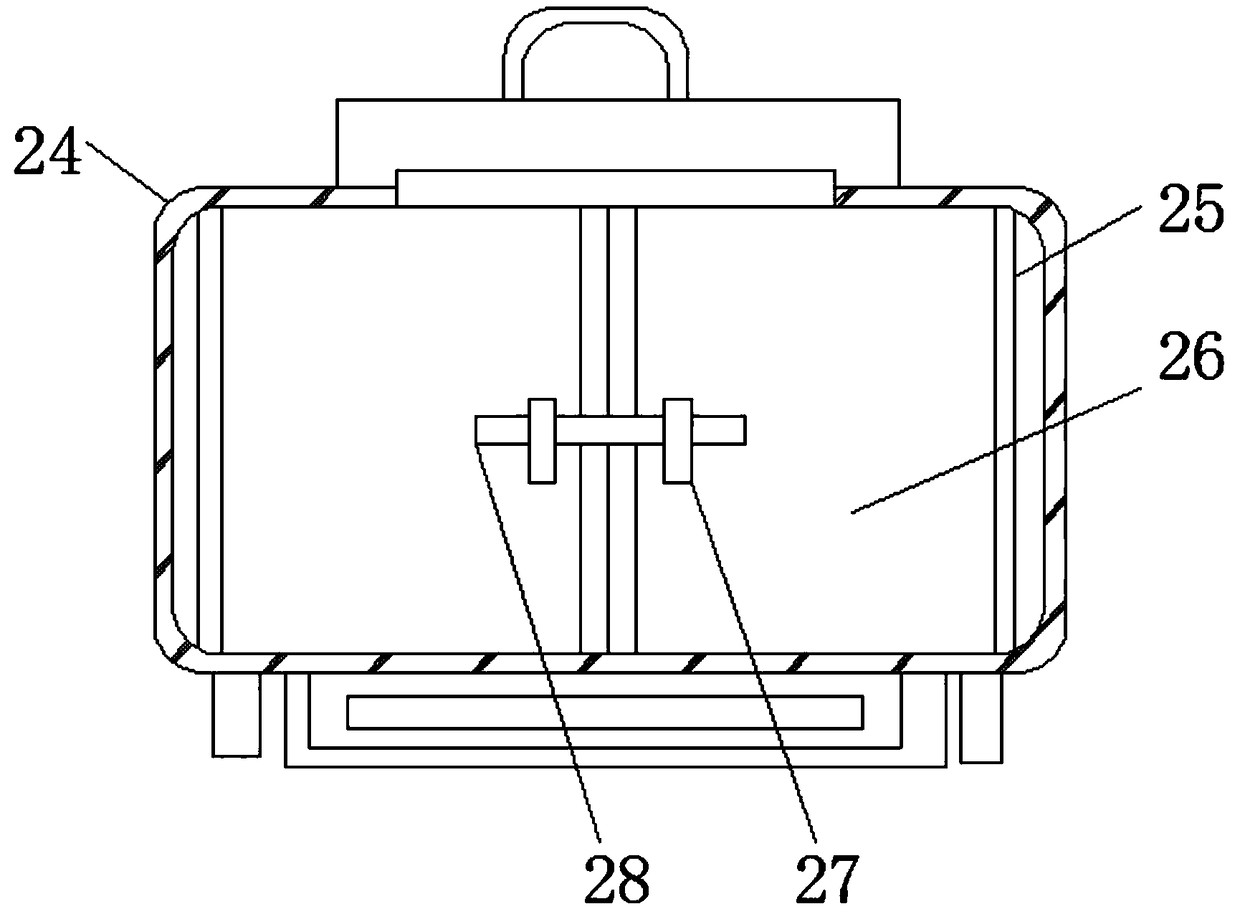

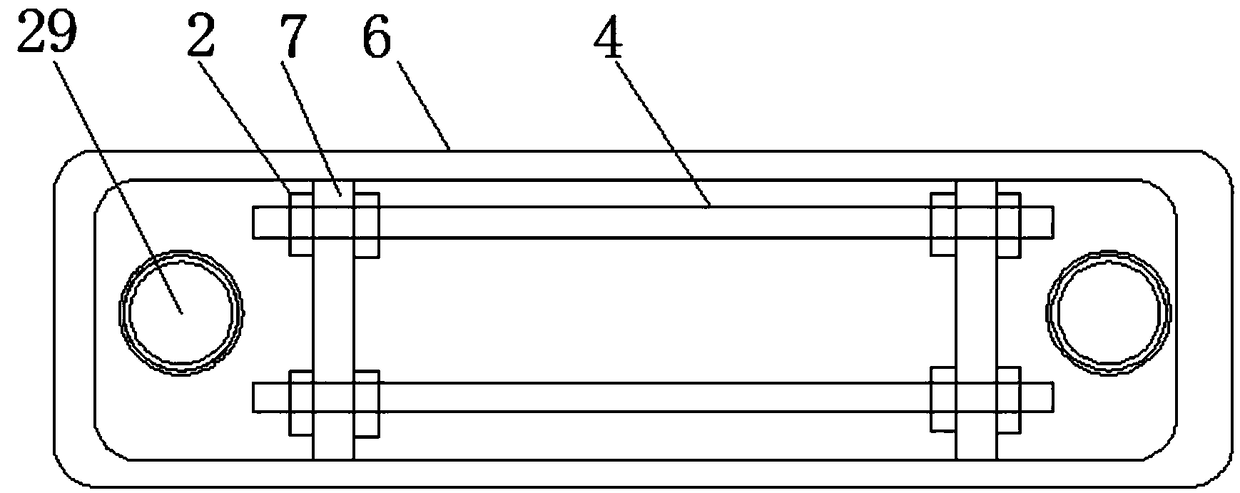

[0025] according to Figure 1-3 A transport device for prefabricated assembled reinforced concrete components is shown, including a load-bearing groove 15, a shock-absorbing buffer column 12, and a transport box 24, and the transportation in the form of a box enables the reinforced concrete components to be fully transported during the entire transportation process. Protection in all aspects, so that the components will not be affected by moisture during transportation, and the quality of use will be affected by factors such as exposure to the sun. The interior of the transportation box 24 is provided with a built-in cavity 23, and both sides of the built-in cavity 23 are provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com