Mobile soil quick dryer suitable for sticky soil

A fast drying and mobile technology, applied in dryers, drying solid materials, drying gas layout, etc., can solve problems such as failure to meet sowing requirements, difficulties in mechanized rotary tillage, and slow soil drying. Drying time and effect, effective control of model volume, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

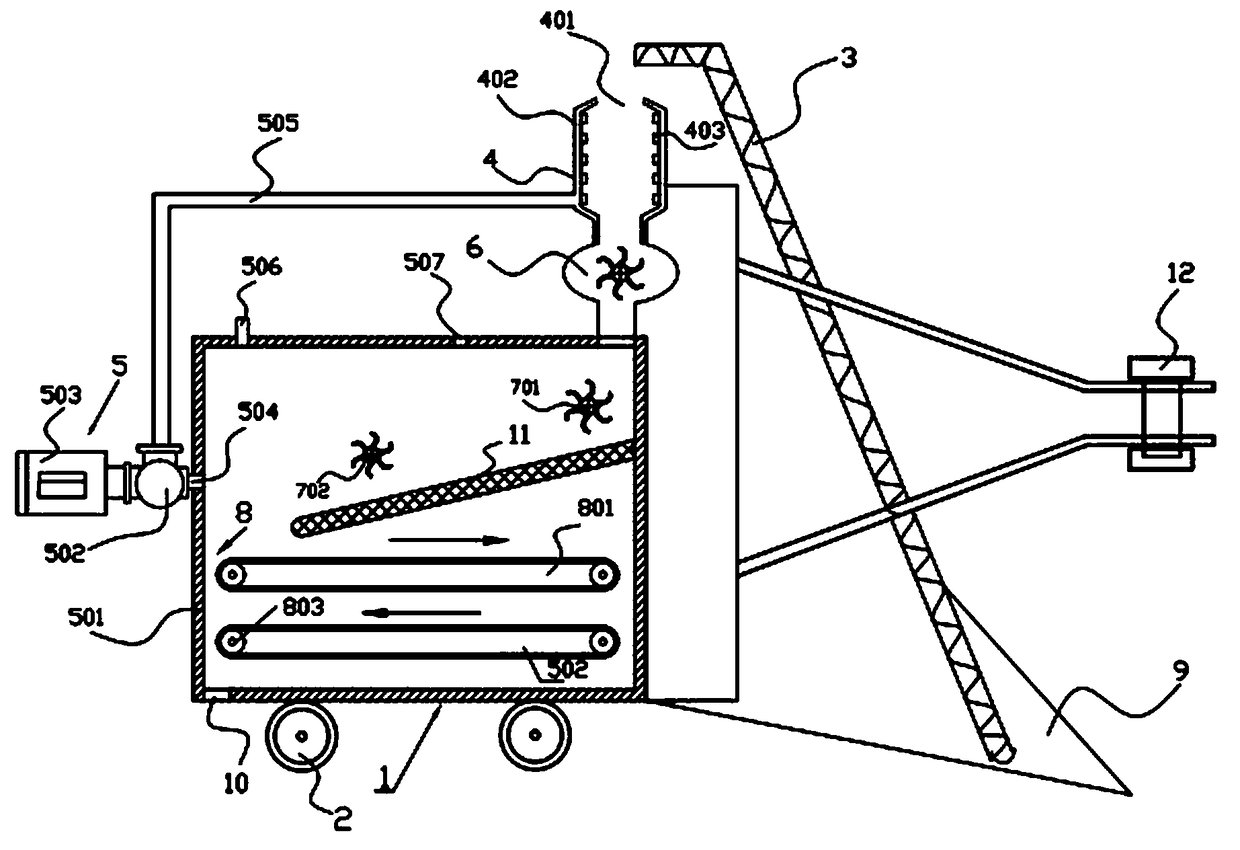

[0031] Such as figure 1 As shown, a mobile soil rapid drying machine suitable for sticky and wet soil, including a body 1 and a walking assembly 2 arranged at the bottom of the body 1, is characterized in that: it also includes a winch arranged in front of the body 1 The dragon conveying assembly 3, the second drying assembly 5 arranged at the rear of the body 1 and the first drying assembly 4 arranged on the upper part of the body 1, a first crushing assembly is arranged between the first drying assembly 4 and the body 1 device 6, the inside of the machine body 1 is provided with a second crushing device 7 and a circuitous soil transport assembly 8, the auger conveying assembly 3 is located between the traction direction of the machine body 1 and the entrance 401 of the first drying assembly 4, the auger One end of the dragon conveying assembly 3 is installed on the bottom of the shovel bucket 9, and the other end is suspended above the entrance 401 of the first drying assemb...

Embodiment 2

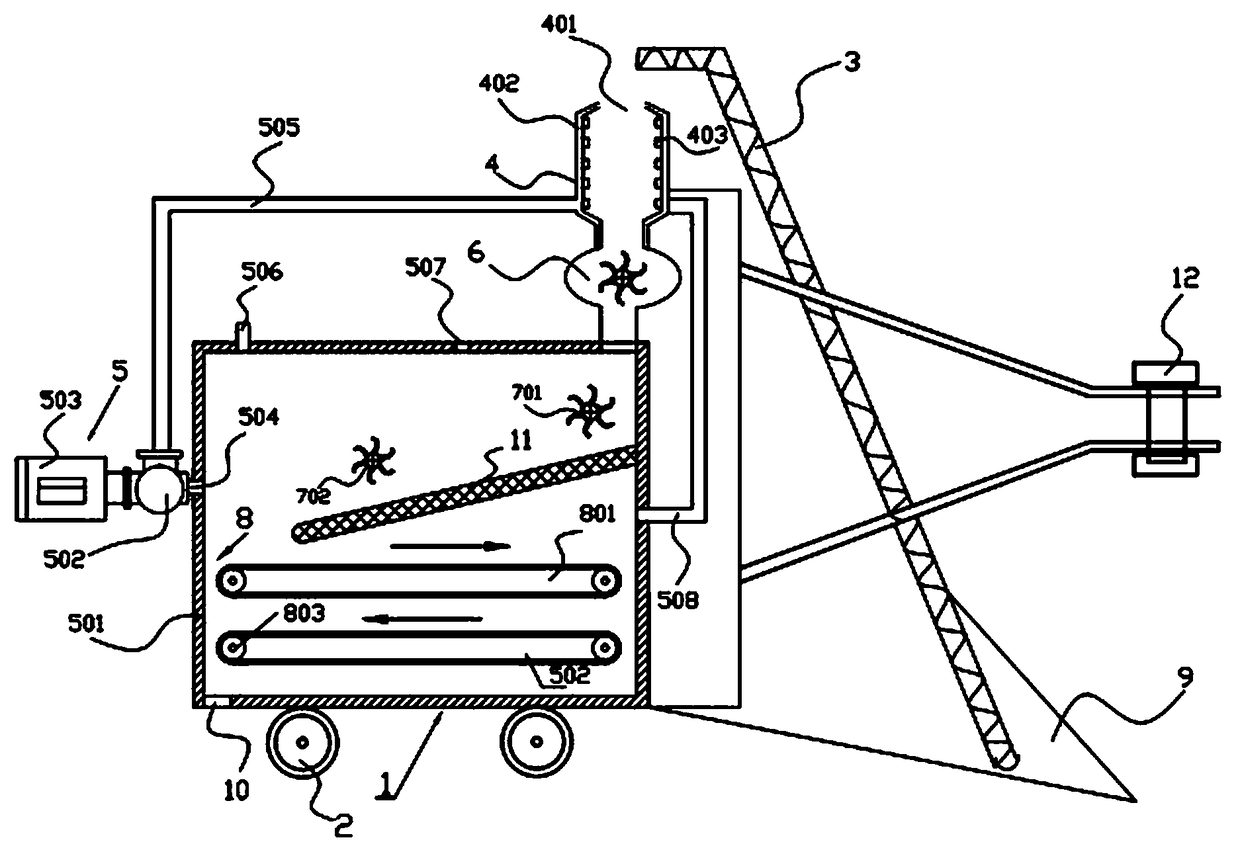

[0043] Such as figure 2 As shown, the difference between embodiment 2 and embodiment 1 is that the exhaust device is set differently. The auxiliary air outlet 508 is connected to the drying cylinder 402, and the heat source can be reused.

Embodiment 3

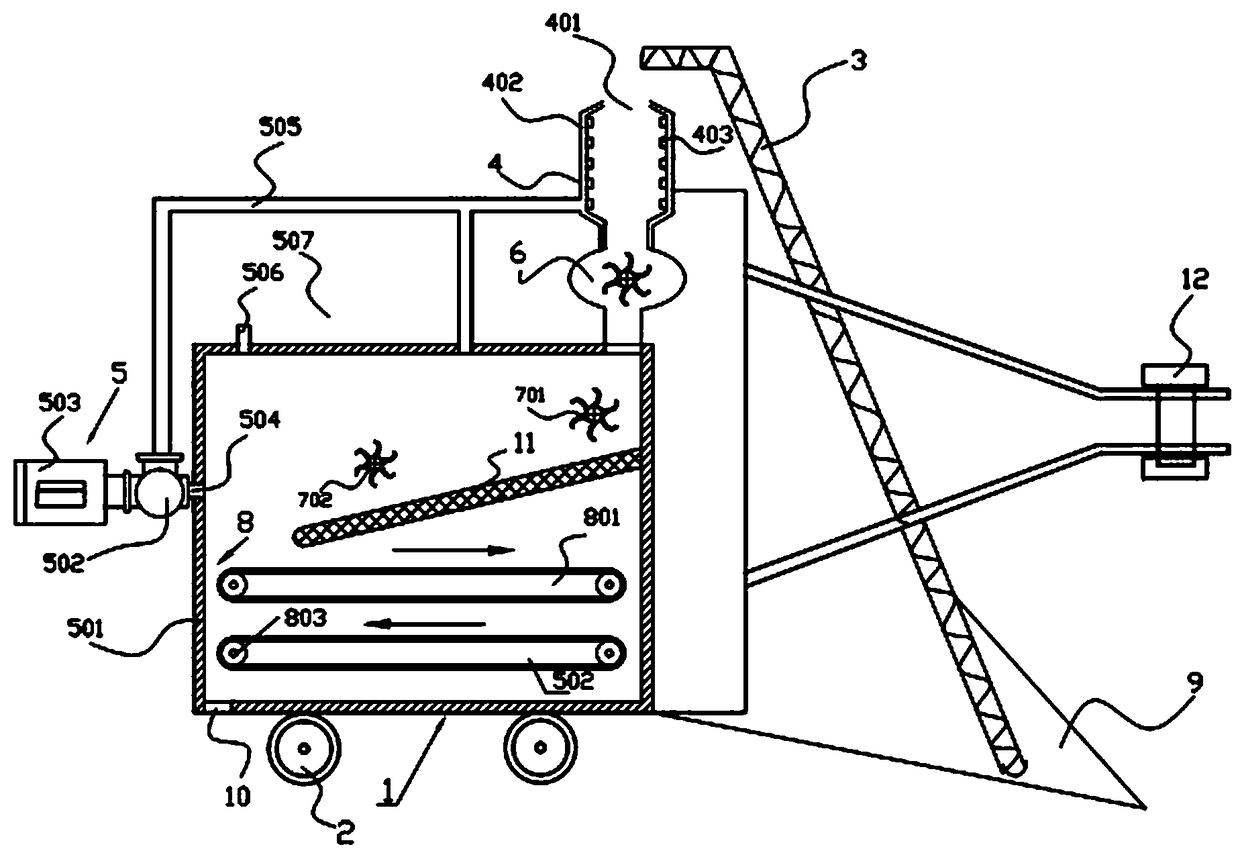

[0045] Such as image 3 As shown, the difference between Embodiment 3 and Embodiment 1 is that the exhaust device is set differently. An auxiliary air outlet 508 is provided at the air outlet 507 of Embodiment 1, and the auxiliary air outlet 508 is communicated with the second hot air pipe 505. Connected, the remaining heat source or waste heat is discharged into the drying cylinder through the second hot air pipe 505 for reuse.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com