A superconduct magnet based on a high-temperature superconduct circular ring piece

A superconducting magnet, high temperature superconducting technology, applied in superconducting magnets/coils, magnetic objects, electrical components, etc., can solve the problems of increasing cooling cost, power loss, immature welding process, etc., and achieve convenient manufacturing and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

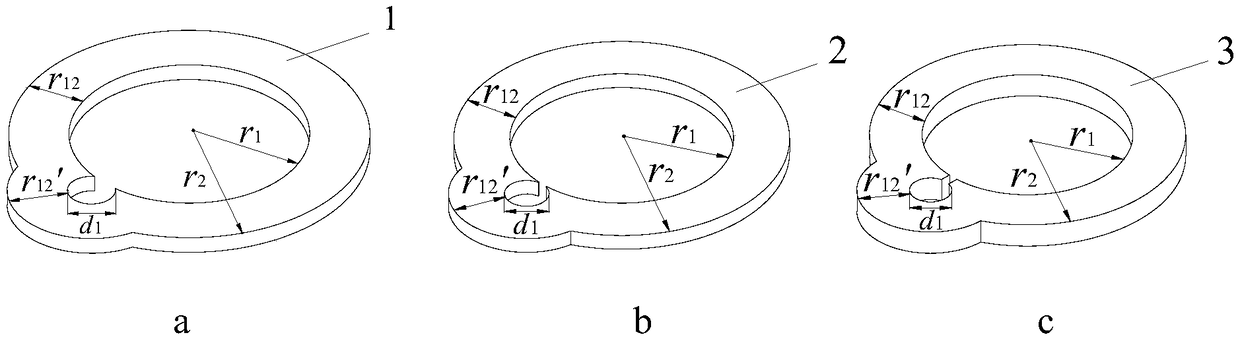

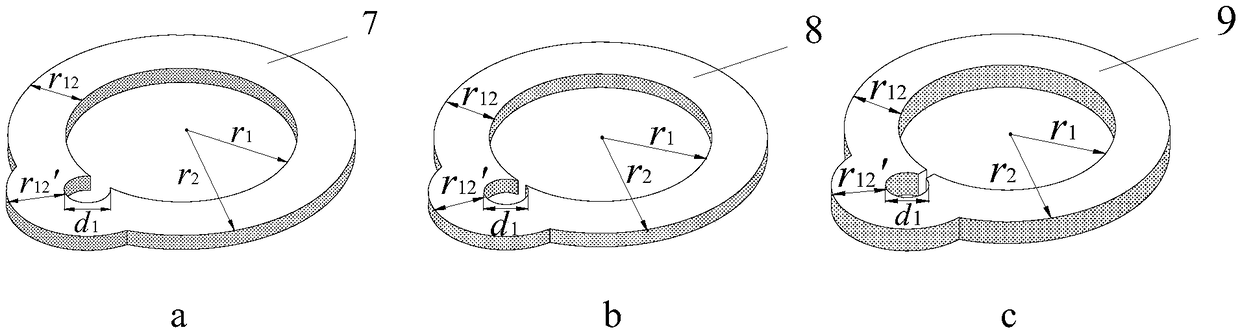

[0026] Embodiment 1: When the inner diameter of the required superconducting magnet is large and the difference between the inner and outer radii of the superconducting ring is small, the superconducting ring should be made wider on one side to ensure that the superconducting ring is cut out after the positioning hole The overall width is the same.

[0027] Firstly, according to the radial width required by the superconducting ring, one side of the superconducting ring is designed to be wider. This side is used to cut out the positioning hole for placing the magnetic flux pump coil. The size of the positioning hole is slightly larger than the outer diameter of the coil. Diameter size. According to the positions of the positioning holes, the superconducting rings are divided into three structures, namely intersecting type, tangent type and phase separation type. Then the part on the line between the center of the positioning hole and the center of the superconducting ring is c...

Embodiment approach 2

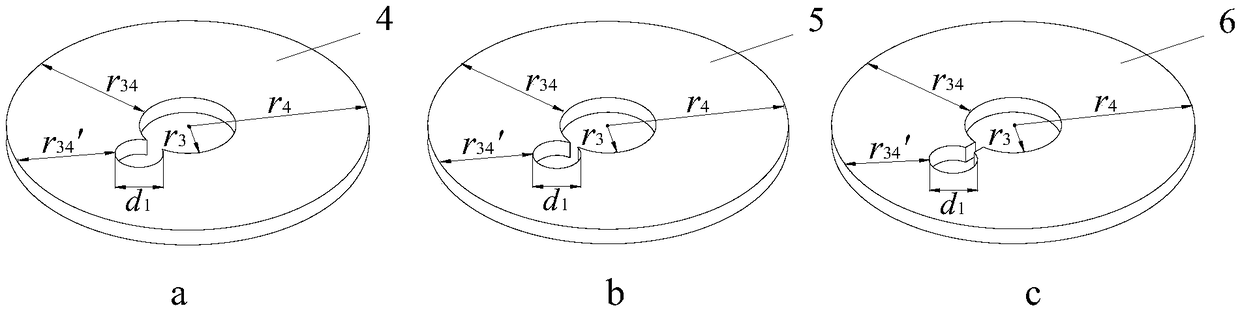

[0028] Embodiment 2: When the inner diameter of the required superconducting magnet is small and the difference between the inner and outer radii of the superconducting ring is large, a positioning hole is cut on the inner diameter side of the superconducting ring.

[0029] Firstly, according to the size required by the superconducting ring, adopt the mature existing cutting process to cut out the fixed positioning hole on the inner diameter side of the produced superconducting ring, and the size of the positioning hole is slightly larger than the outer diameter of the coil part. According to the positional relationship between the positioning hole and the inner ring of the superconducting ring, the superconducting ring is divided into three structures, that is, intersecting, tangent, and separated. Then cut the part on the line between the center of the positioning hole and the center of the circle of the superconducting ring, so that the cutting hole communicates with the ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com