A TSV hole filling method

A technology of aperture and blind hole, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as poor effect, low filling rate, and excessively thick surface Cu layer, to simplify operation complexity and reduce processing. Effects of difficulty, good orifice condition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Hereinafter, the present invention will be further described in conjunction with the drawings and specific embodiments.

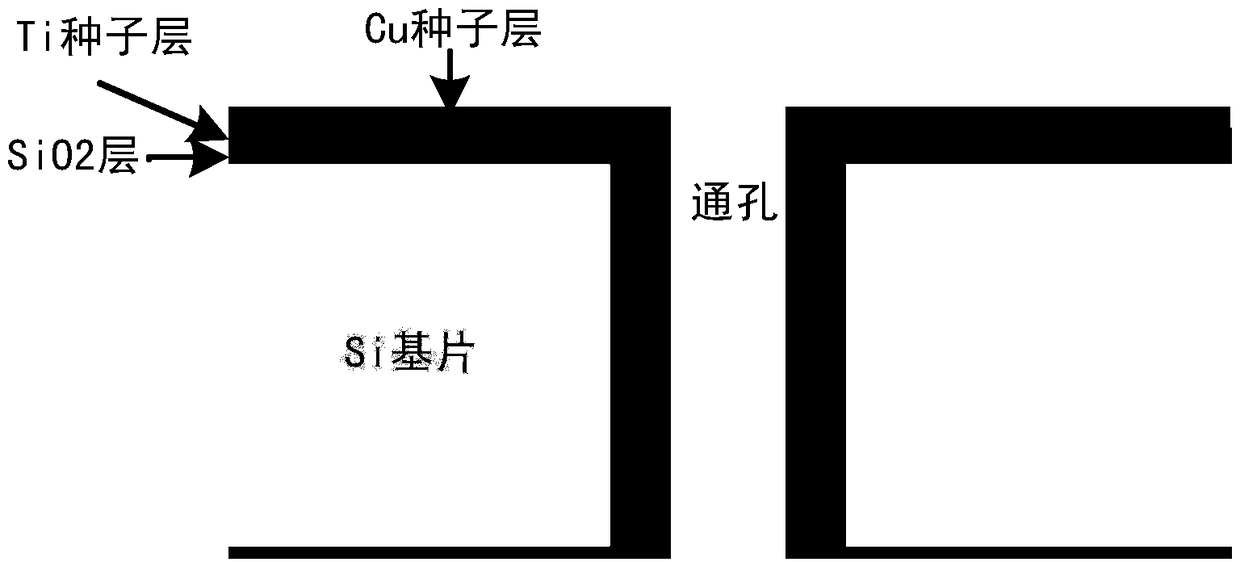

[0045] Such as Figure 1 to 4 As shown, a TSV hole filling method specifically includes the following steps:

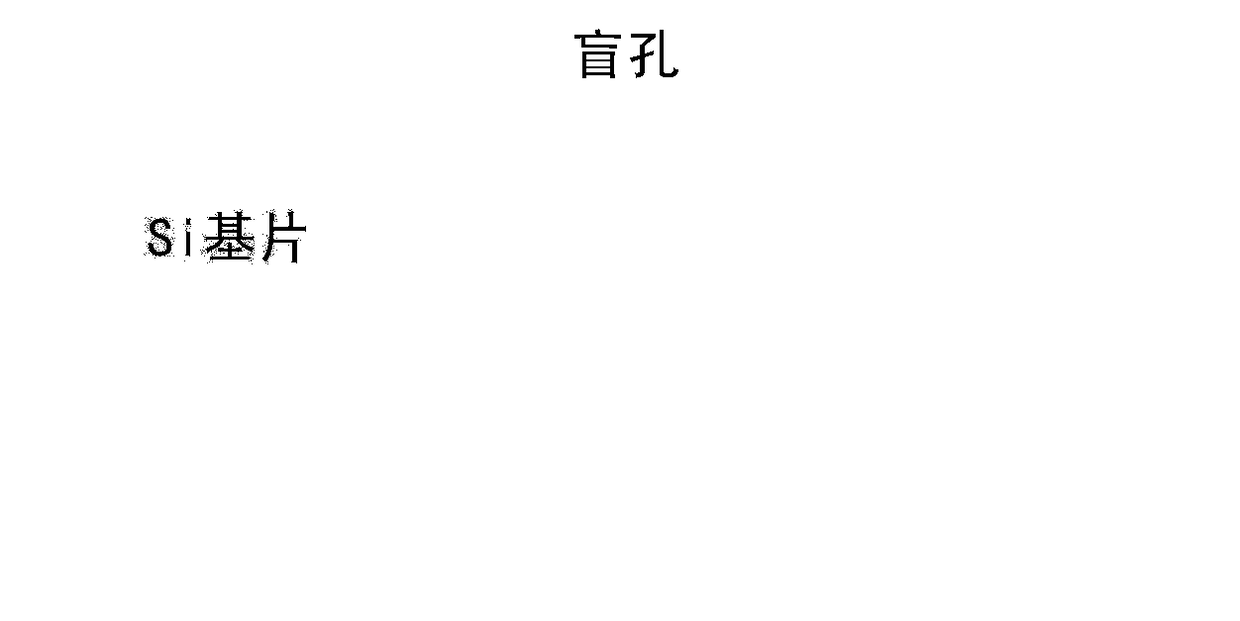

[0046] (1) Perform photolithography and etching on the front surface of the Si substrate to obtain blind holes with a diameter of 5 to 150 μm and a depth of 100 to 350 μm, and then remove the glue. The processed structure is as follows figure 1 Shown

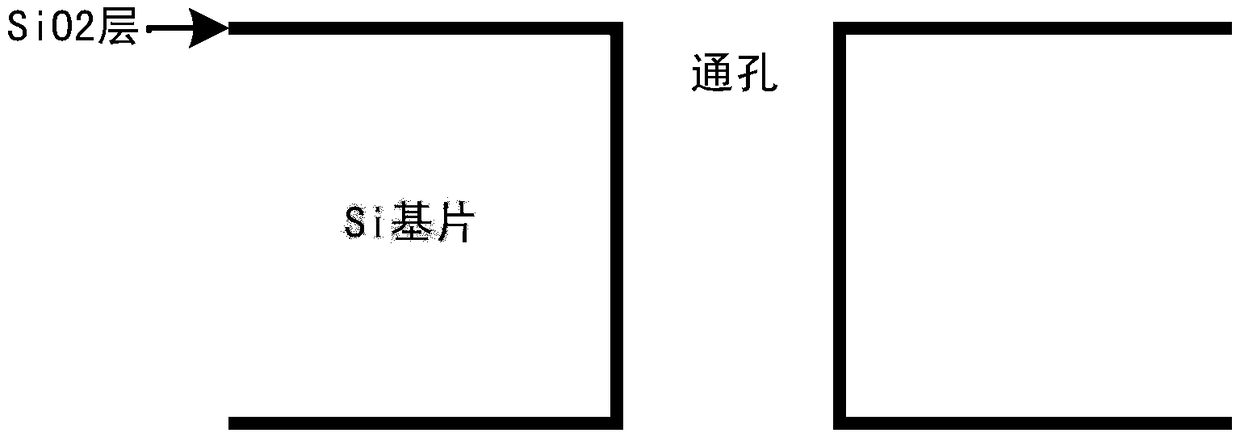

[0047] (2) Grind and polish the back of the substrate treated in step (1) until the etching holes are exposed, clean, dry, and grow SiO on both sides 2 Layer, the processed structure is like figure 2 Shown

[0048] (3) The substrate processed in step (2) is subjected to backside filming treatment;

[0049] When the substrate is subjected to back filming treatment, a filming machine is used to paste UV film, blue film, etc. on the back of the silicon wafer, and the excess film is cut along the edge of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com