micropore manufacturing method and a structure of a PCB substrate

A manufacturing method and microporous technology, applied in printed circuit manufacturing, electrical connection printed components, electrical components, etc., can solve the problems of high R&D and production costs, reduced volume, and no equipment, so as to increase circuit density and reduce hole size , Improve the effect of circuit integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

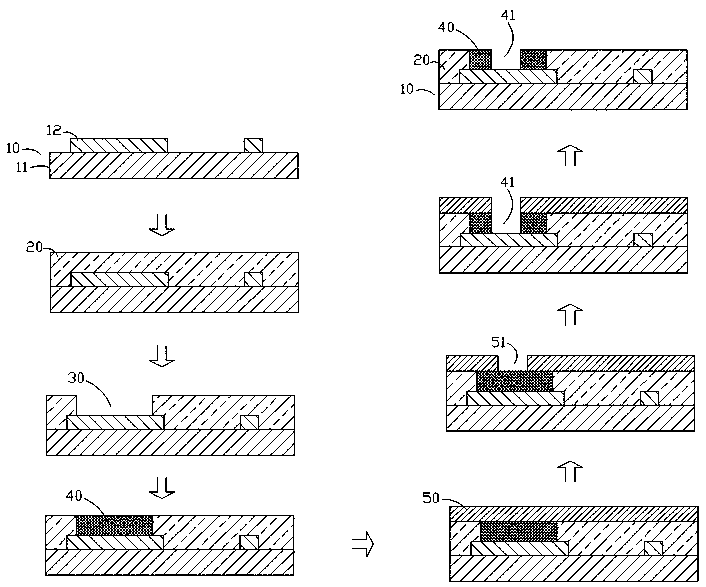

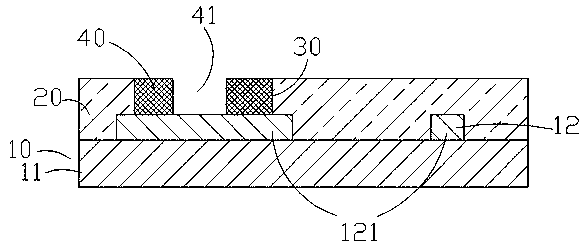

[0018] Such as Figures 1 to 2 As shown, a method for manufacturing microholes on a PCB substrate includes the following steps.

[0019] The first step is to manufacture the circuit board 10 .

[0020] The circuit board 10 includes a substrate layer 11 and a copper-clad circuit layer 12, the copper-clad circuit layer 12 is arranged on the top surface of the substrate layer 11, and the copper-clad circuit layer 12 is pressed on the substrate layer 11 top surface The circuit board 10 is formed on the substrate, the copper-clad circuit layer 12 is processed into a predetermined circuit pattern, and the substrate layer 11 includes a glass fiber layer and an epoxy resin layer.

[0021] In practice, the circuit board layer 10 is formed by laminating the glass fiber layer, the epoxy resin layer and the copper-clad circuit layer 12. The circuit board layer 10 has relevant requirements on the TG value, which is the so-called FR-4 , the TG of general epoxy resin is 120-130°C, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com